Abstract

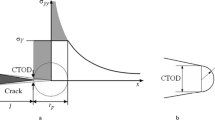

The maximum shear stress theory of failure is extended to consider the crystallographic orientation in a polycrystalline material. At a given point, the angular regions, within which the shear stress is higher than the critical shear stress of the crystal, are calculated and the probability of slip for this crystal is obtained. Since there is little plastic flow associated with fatigue, the stresses can be obtained from theory of elasticity. The probability of failure of components are then calculated from the probability of slip of the individual crystals. Using fatigue results for notched specimens, it is concluded that a propagating crack will only form if a number of neighboring crystals are all orientated to slip.

Résumé

La théorie de la limite critique de l'effort maximum de cisaillement s'étend à l'étude de l'orientation cristallographique d'une matière polycristalline. A un point donné, les parties angulaires où l'effort de cisaillement est plus élevé que l'effort de cisaillement critique du cristal, sont calculées et la probabilité de glissement pour ce cristal est obtenue. Puisqu'un glissement plastique pen important accompagne la fatigue, on peut estimer les efforts d'après la Théorie de l'Elasticité. La probabilité de rupture des composants est alors calculée d'après la probabilité de glissement de chaque cristal. En utilisant les résultats indiquant le degré de fatigue pour des specimens entaillés, on conclue qu'une fissure ne se propage que si un certain nombre de cristaux avoisinants sont tous orientés dans la direction du glissement.

Zusammenfassung

Die maximale Scherkraft Theorie des Bruches ist erweitert um die kristallographische Orientierung in emem aus mehreren Kristallen bestehenden Material zu untersuchen. An einer gegebenen Stelle werden die Winkelbereiche berechnet, in denen die Scherkraft größer ist als die Schubfestigkeit des Kristalles, und die Schiebungswahrscheinlichkeit für diesen Kristall wird erhalten. Da wenig plastische Ausweitung mit Ermüdung verbunden ist, können die Kräfte aus der Elastizitätstheorie erhalten werden. Die Bruchwahrscheinlichkeit der Teile kann dann aus der Schiebungswahrscheinlichkeit der einzelnen Kristallen berechnet werden. Von den Ermüdungsergebnissen für Kerbproben ist zu schließen ein fortschreitender Riß nur entsteht wenn eine Anzahl benachbarter Kristallen alle zur Schiebung orientiert sind.

Similar content being viewed by others

Abbreviations

- σ x :

-

Principal stress in x-direction

- σ y :

-

Principal stress in y-direction

- σ z :

-

Principal stress in z-direction

- α:

-

Angle from x-axis to perpendicular on arbitrary plane

- β:

-

Angle from y-axis to perpendicular on arbitrary plane

- γ:

-

Angle from x-axis to perpendicular on arbitrary plane

- l :

-

cos α, direction cosine

- m :

-

cos β, direction cosine

- n :

-

cos γ, direction cosine

- σ:

-

Direct stress on arbitrary plane

- τ:

-

Shear stress on arbitrary plane

- P A :

-

Angular probability

- τc :

-

Critical shear stress for ductile materials α1 and α2 are values of α at boundary of slip region β1 and β2 are values of β at boundary of slip region

- p 1 :

-

Number of slip planes with lowest critical shear stress

- q :

-

Number of regions of slip in the hemisphere

- I :

-

q 1 \(\int_{\beta _1 }^{\beta _2 } {\int_{\alpha _1 }^{\alpha _2 } {} }\) dαdβ

- V :

-

Volume of overstressed material

- ν :

-

Average crystal volume

- P n1 :

-

Probability of failure of a fatigue specimen

- n 1 :

-

Minimum number of neighboring crystals with continuous slip bands required to form a propagating crack

- A,B,C :

-

Coefficients

- m 1 :

-

cos β1

- m 2 :

-

cos \gB2

- ν:

-

Angle

- M xx :

-

Bending moment on section x−x of fatigue specimen

- d :

-

Diameter of section x−x

- σn :

-

Nominal stress

- r :

-

Notch radius

References

S. Timoshenko, Strength of Materials, Part II, 3rd ed., D. van Nostrand Co., Inc., New York (1956).

G. Sines and J. L. Weisman (eds.), Metal Fatigue, McGraw-Hill Book Co., Inc., New York (1959).

A. E. H. Love, A Treatise on the Mathematical Theory of Elasticity, 4th ed., Cambridge University Press (1952).

M. T. Huber, Czasopismo Technizne, Lwov (Lemberg) (1904).

R. von Mises, Göttinger Nachrichten, Math. Phys. Kl., (1913) 582.

A. Eichinger, Proc. 2nd Inter. Congr. Appl. Mech., Zürich, (1926) 325.

C. S. Barrett, Structure of Metals, McGraw-Hill Book Co., Inc., New York (1952).

A. J. Opinsky and J. Smoluchowski, Appl. Phys., 22 (1951) 1488.

J. M. Hedgepeth, “Theoretical Distribution of Slip Angles in an Aggregate of Face-Centered Cubic Crystals,” NACA TN 2777 (1952).

E. Maurer and R. Mailänder, Stahl und Eisen, 45, (1925) 409.

S. Timoshenko, Theory of Elasticity, McGraw-Hill Book Co., Inc., New York (1934).

T. H. Lin and M. Ito, J. Mech. Phys. Solids, 13 (1965) 103–115.

N. E. Frost and D. S. Dugdale, J. Mech. Phys. Solids, 5 (1957) 182–192.

N. E. Frost, J. Mech. Phys. Solids, 9 (1961) 143–151.

W. Sawert, Z. ver. deut. Ing., 87 (1943) 39/40, 609–615.

H. F. Moore, Proc. ASTM, 45 (1945) 508–522.

H. F. Moore and D. Morkovin, Proc. ASTM, 43 (1943) 109.

R. E. Peterson and A. M. Wahl, J. Appl. Mech., 3–5, A-15 (1936–38).

H. F. Moore and R. L. Jordan, Proc. 5th Inter. Congr. Appl. Mech., John Wiley and Sons, New York (1939).

American Society for Testing and Materials, Manual on Fatigue Testing, ASTM, Cleveland, 101.

H. Neuber, Theory of Notch Stresses, J. W. Edwards Publisher Inc., Ann Arbor, translation (1946).

M. A. Grossman and E. C. Bain, Principles of Heat Treatment, ASM, Metals Park, Ohio (1964).

T. H. Lin and S. Uchiyama, J. Mech. Phys. Solids, 11, (1963) 327–343.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ørbeck, F. A theory of failure based on probability for fatigue of ductile materials. Int J Fract 5, 85–99 (1969). https://doi.org/10.1007/BF00187206

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00187206