Abstract

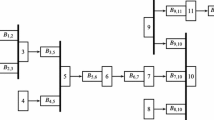

We consider an assembly line with m stations in series having finite-capacity buffers. Blocking occurs when buffers are full. There are M different types of products to be assembled, each with its own processing requirements. There is a production target set for each type. We give tight bounds on how long it takes such a system to reach steady state for a given cyclic schedule.

Similar content being viewed by others

References

AhoA.V., HopcroftJ.E. and UllmanJ.D., The Design and Analysis of Computer Algorithms, Addison-Wesley, Reading, MA (1974).

AkellaR., ChoongY.F. and GershwinS.B., “Performance of Hierarchical Production Scheduling Policy,” IEEE Transactions on Components, Hybrids, and Manufacturing Technology, CHMT-7, Vol. 3, pp. 225–240 (1984).

BoxmaO.J., “On a Tandem Queueing Model with Identical Service Times at Both Counters,” Advanced Applied Probability, Vol. II, pp. 616–689 (1979).

Cohen, G., Dubois, D., Quadrat, J.P. and Viot, M., “A Linear-System-Theoretic View of Discrete Event Processes,” Proceedings of the 22nd IEEE Conference on Decision and Control, San Antonio, TX (1983).

Cunninghame-GreenR.H., “Describing Industrial Processes and Approximating Their Steady State Behavior,” Operations Research Quarterly, Vol. 13, pp. 95–100 (1962).

Cunninghame-GreenR.H., “Projections in a Max-Min Algebra,” Mathematical Programming Vol. 10, pp. 111–123 (1976).

GershwinS., AkellaR., and ChoongY.F., “Short Term Scheduling of an Automated Manufacturing Facility,” IBM Journal of Research and Development, Vol. 29, pp. 392–400 (1985).

HitzK.L., “Scheduling of Flexible Flow Shops,” Report No LIDS-TH-1063, Laboratory for Information and Decision Systems, Massachusetts Institute of Technology, Cambridge, MA (1979).

HitzK.L., “Scheduling of Flow Shops. II,” Report No. LIDS-R-879, Laboratory for Information and Decision Systems, Massachusetts Institute of Technology, Cambridge, MA (1980).

JohnsonL.A., and MontgomeryD.C., Operations Research in Production Planning, Scheduling and Inventory Control, Wiley, New York (1974).

LevnerE.M., “Optimal Planning of Parts Machining on a Number of Machines,” Automation and Remote Control, Vol. 12, pp. 1972–1981 (1969).

McCormickS.T., PinedoM.L., ShenkerS., and WolfB., “Sequencing in an Assembly Line with Blocking to Minimize Cycle Time,” Operations Research, Vol. 37, pp. 925–935 (1989).

WittrockR.J., “Scheduling Algorithms for Flexible Flow Lines,” IBM Journal of Research and Development, Vol. 29, pp. 401–412 (1985).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

McCormick, S.T., Pinedo, M.L., Shenker, S. et al. Transient behavior in a flexible assembly system. Int J Flex Manuf Syst 3, 27–44 (1991). https://doi.org/10.1007/BF00167524

Issue Date:

DOI: https://doi.org/10.1007/BF00167524