Abstract

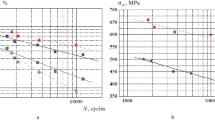

Literature (mainly in Japan) relating to fatigue-crack-growth-data at R=0 in an air environment for a wide range of steels is reviewed with particular attention to the threshold stress intensity, ΔK th. The collected data are analyzed in terms of the exponent, m(the slope of the linear portion of the log(da/dN)-logΔD relationship) by taking account of microstructure, material strength, fracture toughness and specimen thickness. The mean rate of fatigue crack growth for ductile steels in the range from the intermediate growth rate to threshold level and the relevant threshold values at R=0, ΔK th0, can be represented asda/dN = 1.700 × 10-4(ΔK103.6)m - 10-6andΔK th0 = 103.6(5.88 × 10-3)1/m,where (da/dN) and ΔK are measured by the units of mm/cycle and kgf/mm3/2, respectively. Contrary to this, in the case of extremely brittle steels with K IC-value below 200 kgf/mm3/2 (the fracture occurs by the intergranular separation), the relationships are given byda/dN = 2.893 × 10-5(ΔK/49.94)m - 2.5 × 10-7andΔK th0 = 49.94(8.64 × 10-3)1/m.

Résumé

La littérature, principalement japonaise, relative aux données sur la propagation des fissures de fatigue pour R=0 dans un environnement d'air et pour une large catégorie d'aciers fait l'objet d'une revue avec une attention particulière pour l'intensité de contrainte de seuil, K th. Les données collectées sont analysées en terme de l'éxposant m (qui représente la pente de la portion linéaire de la relation log(da/dN)-log ΔK, en tenant compte de la microstructure, de la résistance du matériau, de la ténacité à la rupture et de l'épaisseur de l'éprouvette. La vitesse moyenne de propagation d'une fissure de fatigue dans le cas des aciers ductiles dans la fourchette entre la vitesse intermédiaire de fissuration et le niveau critique, et les valeurs correspondantes de seuil à R=0, ΔK th0 peuvent être représentées par la relation:da/dN = 1.700 × 10-4(ΔK103.6)m - 10-6etΔK th0 = 103.6(5.88 × 10-3)1/m,où (da/dN) et ΔK sont mesurés en unités de mm/cycle et en kgf/mm3/2 respectivement. En contraste, dans le cas d'aciers extrèmement fragiles avec des valeurs K IC en dessous de 200 kgf/mm3/2 (la rupture se produit par une séparation intergranulaire), ces relations sont données par:da/dN = 2.893 × 10-5(ΔK/49.94)m - 2.5 × 10-7etΔK th0 = 49.94(8.64 × 10-3)1/m.

Similar content being viewed by others

References

C.J. Beevers, Proceedings, International Conference on Fracture 4, Waterloo, Canada, 1 (1977) 239.

P.C. Paris and F. Erdogan, Journal of Basic Engineering, Transactions ASME, D85 (1963) 528.

R.O. Ritchie, Metal Science, 11 (1977) 368.

M. Klesnil and P. Lukas, Materials Science and Engineering, 9 (1972) 231–240.

E. Sasaki, A. Ohta and M. Kosuge, Transactions National Research Institute for Metals, 19 (1977) 183–199.

R.J. Cooke, P.E. Irving, G.S. Booth, and C.J. Beevers, Engineering Fracture Mechanics 7 (1975) 69.

H. Kitagawa and M. Misumi, Proceedings, International Conference on Mechanical Behaviors of Materials, Kyoto, 2 (1972) 218.

H. Koshiga and M. Kawahara, (in Japanese), Journal of the Society of Naval Architects of Japan 153 (1973) 305–312.

T. Yokobori, I. Kawada and H. Hata, Research Institute for the Strength of Fracture of Materials, 9 (1973) 35–64.

T. Yokobori and T. Aizawa, Research Institute for the Strength of Fracture of Materials, 9 (1973) 65–67.

K. Tanaka and S. Matsuoka, International Journal of Fracture, 13 (1977) 563–583.

P.N. Thielen and M.E. Fine, Metallurgical Transactions 6 (1975) 2133.

A.A. Antil and E.B. Kula, ASTM STP 462 (1971) 297.

G.A. Miller, Transactions ASM, 61 (1968) 442–448.

R.O. Ritchie and J.F. Knott, Acta Metallurgica 21 (1973) 639–648.

C.E. Richards and T.C. Lindley, Engineering Fracture Mechanics 4 (1972) 951–978.

S. Horibe, R. Sagawa, T. Fujita and T. Araki, (in Japanese), Tetsu-to-Hagane (Journal of the Iron and Steel Institute of Japan), 64 (1978) 84–93.

S. Horibe, Y. Seki, T. Fujita and T. Araki, Tetsu-to-Hagane (Journal of the Iron and Steel Institute of Japan), 64 (1978) 94–103.

M. Kikukawa, M. Jono, K. Tanaka and M. Takatani, (in Japanese) Journal of the Society for Material Science (Japan), 25 (1976) 899–903.

C. Masuda and S. Nishijima, Journal of the Society for Material Science (Japan), 27 (1978) 59–63.

R. Murakami, H. Kobayashi, and H. Nakazawa, (in Japanese), Reprints of Japanese Society of Mechanical Engineers, No. 750-13 (1975) 303.

R. Murakami, H. Kobayashi, A. Komine, and H. Nakazawa, Ibid., No. 760-2 (1976) 233–244.

R. Murakami, H. Kobayashi, and H. Nakazawa, Ibid., No. 770-2 (1977) 151–158.

E. Shibuya, H. Kobayashi, and H. Nakazawa, Ibid., No. 760-13 (1976) 191–193.

K. Fujita, H. Kobayashi, A. Komine and H. Nakazawa, Ibid., No. 760-13 (1976) 216–218.

H. Kobayashi, Ibid., No. 760-9 (1976) 1.

Y. Kitsunai and M. Tanaka, Ibid., No. 760-2 (1976) 229 and No. 760-9 (1976) 35.

H. Nishitani and M. Murata, Ibid., No. 760-2 (1976) 217.

H. Kitagawa and S. Takahashi, Ibid., No. 760-2 (1976) 213.

A. Otsuka, K. Mori, and K. Kawamura, Ibid., No. 760-13 (1976) 249.

C.J. Beevers, R.J. Cooke, J.F. Knott, and R.O. Ritchie, Metal Science, 9 (1975) 119.

C.M. Branco, J.C. Radon and L.E. Culver, Metal Science, 10 (1976) 149.

P.E. Irving and L.N. McCartney, Metal Science, 11 (1977) 351.

R. Mclester, Metal Science, 11 (1977) 303.

R.J. Cooke and C.J. Beevers, Materials Science and Engineering 13 (1974) 201

L.P. Pook, ASTM STP513, (1972) 106–124.

P.C. Paris, R.J. Bucci, E.T. Wessel, W.G. Clark, and T.R. Mager, Ibid., (1972) 141.

J. Masounave and J.P. Bailon, Scripta Met., 9 (1975) 723–730 and 10 (1976) 165–170.

K. Sumida and I. Uchiyama, Unpublished work in NRIM.

T.R. Gurney, Metal Const., 1 (1969) 91–96.

S.J. Maddox, Welding Institute Research Report E/48/72 (1972).

J.M. Barsom, E.J. Imnof and S.T. Rolfe, Engineering Fracture Mechanics, 2 (1971) 301.

K. Kobayashi, A. Narumoto, T. Funakoshi, and Hirai, (in Japanese), Kawasaki Steel Technical Report, 8 (1976) 336.

H. Kitagawa and T. Matsumoto, (in Japanese), Journal of the Japanese Society of Mechanical Engineers, 43 (1977) 2421.

P. Lukas and M. Klesnil, Engineering Fracture Mechanics 8 (1976) 621–629.

W. Elber, ASTM STP 486, (1971) 230–242.

V. Weiss and D.N. Lal, Metallurgical Transactions 5 (1974) 1946–1949.

S. Majumdar and JoDean Morrow, ASTM STP 559, (1974) 159–182.

T. Yokobori, A.T. YokoboriJr., and A. Kamei, International Journal of Fracture, 11 (1975) 781–788.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tanaka, K. A correlation of ΔK th-value with the exponent, m, in the equation of fatigue crack growth for various steels. Int J Fract 15, 57–68 (1979). https://doi.org/10.1007/BF00115909

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00115909