Abstract

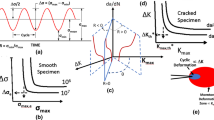

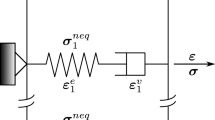

The fatigue process, viewed as a sequence of slow growth periods, is described by a non-linear differential equation of the first order which includes the “creep component” of crack growth in a visco-elastic solid. It is shown that fracture in a rate sensitive medium may extend even under sustained or decreasing loads. The total rate of growth consists therefore of two terms where the first term is a familiar power law, valid for a high-cycle range and limited plasticity effects, while the second one accounts for the time-dependent contribution. Here f denotes frequency, Y is the yield stress, Kcdenotes fracture toughness, ΔK stands for the stress intensity range while the crack closure correction α, the rate sensitivity C and the constant R * are defined in the text.

Résumé

Le processus de fatigue, lorsqu'on le considère comme une séquence de périodes de croissance lente de microfissures, peut être décrit par une équation différentielle non linéaire du premier ordre, qui comporte la composante “fluage” de la croissance de la fissure dans un solide viscoélastique. On montre que la rupture dans un corps sensible à la vitesse de sollicitation peut s'étendre même sous des charges à amplitude constante, voire décroissante.

La vitesse totale de croissance la fissure comporte donc deux termes

Le premier est la relation parabolique familière, valable pour le domaine d'endurance où la plasticité n'a que des effets limités. Le second exprime la contribution du facteur temps. La fréquence est représentée par f, la limite élastique par Y, et la ténacité par Kc; ΔK désigne la variation du facteur d'intensité des contraintes α la correction de fermeture de la fissure, C la sensibilité à la vitesse de déformation et R une constante. Ces trois derniers paramètres sont définis dans le texte.

Zusammenfassung

Der Müdigkeitsvorgang, bestehend aus einer Reihenfolge von langsamen Wachstumsperioden, wird durch eine nicht lineare Gleichung vom ersten Grad, die die “Kriechkomponente” der Rißausbreitung in einem zähflüssig elastischen Körper enthält, dargestellt. Man zeigt daß der Bruch sich, in einem Geschwindigkeits empfindlichen Medium, auch unter Dauerlast oder abnehmender Last ausbreiten kann. Daher besteht die Wachstumsgeschwindigkeit aus zwei Begriffen wovon der erste ein bekanntes Leistungsgesetz ist gültig im Dauerfestigkeitsbereich und für beschränkte plastische Effekte, weil der zweite den zeitabhängigen Anteil berücksichtigt. Mit f=Frequenz, Y=Elastizitätsgrenze, Kc=Bruchzähigkeit, ΔK=Bereich der Spannungsintensität während die Rißschliessungskorrektur α, die Geschwindigkeitsempfindlichkeit C und die Unveränderliche R im Text bestimmt werden.

Similar content being viewed by others

References

S. Arad, J. C. Radon and L. E. Culver, Fatigue Crack Propagation in Polymethylmethacrylate; The Effect of the Man Value of Stress Intensity Factor, J. Mech. Eng. Science, 13, (1971) 75–81.

S. Arad, J. C. Radon and L. E. Culver, Design Against Fatigue Failure in Thermoplastics, Eng. Fracture Mech., 4 (1972) 511–522.

J. M. Barsom, Corrosion-Fatigue Crack Propagation Below KISCC, Eng. Fracture Mechanics, 3 (1971) 15–25.

H. F. Borduas, L. E. Culver and D. J. Burns, Fracture Mechanics Analysis of Fatigue Crack Propagation in PMMA, J. Strain Analysis, 3, 3 (1968) 193.

G. P. Cherepanov, H. Halmonov, On the Theory of Fatigue Crack Growth, Eng. Fracture Mechanics, 4 (1972) 219–230.

W. Elber, Fatigue Crack Closure Under Cyclic Tension, Eng. Fracture Mechanics, 2 (1970) 37–45.

R. G. Forman, V. E. Kearny and R. M. Engle, Numerical Analysis of Crack Propagation in Cyclic-Loaded Structures, J. Basic Engng., Trans. AMSE, 89 (1967) 459.

J. M. Krafft, Strain-Hardening vs. Stress-Relaxation Effects on Fatigue Crack Propagation, Report of NRL Progress, July 1971.

R. W. Hertzberg, J. A. Manson and W. C. Wu, Structure of Polymers and Fatigue Crack Propagation, Tech. Report of Materials Res. Center, Lehigh University, presented at Int. Comf. on Dynamic Crack Propagation, July, 1972.

H. W. Liu, Fracture Criteria of Cracked Metallic Plates, Int. J. Fracture Mech., 2 (1966) 393.

B. Mukherjee, L. E. Culver and D. J. Burns, Growth of Part-through and Through-thickness Fatigue Cracks in Sheet Glassy Plastics, Expl. Mechanics, 9, 2 (1969) 90.

H. Nakazowa, T. Koizumi, H. Honma and H. Sayanaghi, The Effect of Mean Stress on Fatigue Crack Initiation and Propagation, Bull. Japan Soc. Mech. Engrs., 12, 53 (1969) 958.

P. C. Paris, The Fracture Mechanics Approach to Fatigue, Proceedings 10th Sagarnore Army Materials Research Conference, Syracuse University, 1964.

P. C. Paris and G. C. Sih, Stress Analysis of Cracks, ASTM, STP 381, Fracture Toughness Testing and Its Application, 1965, p. 30.

S. Pearson, The Effect of Mean Stress on Fatigue Crack Propagation in Half Inch Thick Specimens of Aluminium Alloys of High and Low Fracture Toughness, RAW Tech. Report 68297 (1968).

B. I. Sandor, Cyclic Stress and Strain, The Univ. of Wisconsin Press, (1972) 85–112.

N. H. Watts and D. J. Burns, Fatigue Crack Propagation in PMMA, Polym. Engng. Sci., 7 (1967) 90.

M. P. Wnuk, Sub critical Growth of Fracture (Inelastic Fatigue), Annual Progress Report prepared at South Dakota State University for the U.S. Navy, Office of Naval Research, August 1970, also Int. J. Fracture Mechanics, 7, 4 (1971) 383–407.

M. P. Wnuk, Prior-to-Failure Extension of Flaws Under Monotonic and Pulsating Loadings, Annual Progress Report prepared for NASA at the S.D.S. University, 1971, also Eng. Fracture Mechanics, in print.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wnuk, M.P. Fatigue in rate sensitive solids. Int J Fract 10, 223–226 (1974). https://doi.org/10.1007/BF00113927

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00113927