Abstract

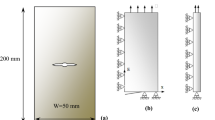

The fatigue crack propagation relation da/dN = f(R)ΔK2 can be derived with three assumptions: small scale yielding, material homogeneity and that crack tip stresses and strains are not strongly affected by plate thickness. f(R) is a constant at a given stress ratio, R. The effects of plate thickness and stress ratio on crack tip deformation and fatigue crack growth in 2024-T351 aluminum alloy were studied. High ΔK level in a thin specimen causes crack tip necking. Necking is more pronounced at high stress ratio. Necking causes high maximum strain near a crack tip, εmax, and fast crack growth rate. In order to avoid the effects of crack tip necking, plates thicker than 2.5 (ΔK/σY(c))2 should be used.

Résumé

La relation de propagation des fissures de fatigue peut être obtenue à partir de trois hypothèses: déformations plastiques de faible étendue, homogénéité du matériau, et relative indifférence à l'épaisseur de la tole des contraintes et déformations à la pointe de la fissure, f(R) est une constante à rapport des contraintes R fixé.

On a étudié les effets de l'épaisseur de la tole et du rapport des contraintes sur la déformation à l'extrémité de la fissure et sur la propagation de la fissure de fatigue, dans le cas de l'alliage d'aluminium 2024-T351. On constate que des valeurs élevées de ΔK appliquées à des échantillons minces produisent une striction aux extrémités de la fissure. Cette striction est plus prononcée aux valeurs élevées de R, et produit une déformation maximum εmax élevée au voisinage de la pointe de la fissure, ainsi qu'une vitesse de propagation élevée.

Pour éviter les effets perturbateurs de la striction aux extrémités d'une fissure, il conviendrait d'utiliser des éprouvettes dont l'épaisseur soit plus forte que 2,5 (ΔK/σY(c))2.

Zusammenfassung

Die Gleichung da/dN = f(R)ΔK2 für Müdigkeitsrißausdehnung kann mittels drei Hypothesen zugestellt werden: kleine plastische Verformungen, Homogenität des Materials, und daß die Spannungen und Verformungen an der Rißspitze nicht stark von der Plattendicke beeinflußt werden. f(R) ist eine Konstante für ein gegebenes Spannungs-verhältnis R. Man untersucht den Einfluß der Plattendicke und des Spannungsverhältnisses auf die Verformungen der Spitze des Risses und der Müdigkeitsrißausdehnung in einer Aluminiumlegierung 2024-T351. Ein hoher ΔK Wert in einer dünnen Probe führt zu Striktion an der Rißspitze. Die Striktion ist stärker für hohe Spannungsverhältnisse. Die Striktion verursacht eine große Höchstspannung E max in der Nähe einer Rißspitze und einen schnellen Rißwachstumsgrad. Zur Vermeidung der Einflüsse der Rißspitzestriktion soll man Platten benutzen die dicker sind als 2,5 (ΔK/σY(c))2.

Similar content being viewed by others

References

P. C. Paris, M. P. Gomez and W. E. Anderson, A Rational Analytic Theory of Fatigue, The Trend in Engineering, 13 (1961) 9.

P. C. Paris and F. Erdogan, A Critical Analysis of Crack Propagation Laws, An ASME publication, Paper No. 62-WA-234.

Herbert H. Johnson and P. Paris, Sub-Critical Flaw Growth, Engineering Fracture Mechanics, 1, 1 (1968).

Kenneth R. Lehr and H. W. Liu, Fatigue Crack Propagation and Strain Cycling Properties, International Journal of Fracture Mechanics, 5, 1 (1969).

H. W. Liu and N. Iino, A Mechanical Model for Fatigue Crack Propagation, Fracture: Proceedings of the Second International Conference on Fracture, Brighton, April 1969.

P. C. Paris, The Fracture Mechanics Approach to Fatigue, Tenth Sagamore Materials Research Conference, Fatigue—An Interdisciplinary Approach, Syracuse University Press, 1964.

B. A. Bibly, A. H. Cottrell and K. H. Swinden, The Spread of Plastic Yield From a Notch, Proc. Roy. Soc. Lond., A272 (1963) 304.

F. A. McClintock, On the Plasticity of the Growth of Fatigue Crack, Fracture of Solids, Met. Soc. AIME Conf., Interscience, New York (1963).

J. R. Rice, Plastic Yielding at a Crack Tip, The First International Conference on Fracture, Sendai, Japan (1965) 283.

J. R. Rice, Mechanics of Crack Tip Deformation and Extension by Fatigue, Fatigue Crack Propagation, ASTM STP 415 (1967) 247.

V. Weiss, Notch Analysis of Fracture, Fracture, An Advanced Treatise, Edited by H. Kiebowitz, Academic Press, New York, 111 (1971) 227.

J. Weertman, Rate of Growth of Fatigue Cracks Calculated From the Theory of Infinitesmal Dislocations Distributed on a Plane, The First International Conference on Fracture, Sendai, Japan (1965) 153.

B. Tomkins, Fatigue Crack Propagation—An Analysis, Phil. Mag., 18, 155 (1968) 1041.

N. E. Frost and J. R. Dixon, A Theory of Fatigue Crack Growth, Intern. Jour. of Fracture Mechanics. 3 (1967) 301.

D. Broek and J. Schijve, The Effect of Sheet Thickness on the Fatigue-Crack Propagation in 2024-T3 Alclad Sheet Material, NLR-TR M 2129, April (1963).

J. M. Krafft, On Prediction of Fatigue Crack Propagation Rate From Fracture Toughness and Plastic Flow Properties, Trans., ASM, 58 (1965) 691.

R. J. Donahue, H. McI. Clark, P. Atanmo, R. Kumble and A. J. McEvily, Crack Opening Displacement and the Rate of Fatigue Crack Growth, IMS Report, Institute of Materials Science, The University of Connecticut (1972).

Maria Roney, Fatigue of High-Strength Materials, Fracture, An Advanced Treatise, Edited by H. Liebowitz, Vol. III, Academic Press (1971).

H. W. Liu, Analysis of Fatigue Crack Propagation, NASA Contractor Report, NASA CR-2032, May 1972.

M. L. Williams, On the Stress Distribution at the Base of A Stationary Crack, Jour. of Applied Mech., (1957) 109–114.

G. R. Irwin, Analysis of Stresses and Strains Near the End of a Crack Traversing a Plate, Jour. of Appl. Mech., (1957) 361–364.

John M. Barsom, Investigation of Sub-critical Crack Growth, Doctoral Dissertation, University of Pittsburgh (1969).

B. J. Schaeffer, H. W. Liu and J. S. Ke, Deformation and the Strip Necking Zone in a Cracked Steel Sheet, Experimental Mechanics, April 1971.

W. G. Clark, Jr. and H. E. Trout, Jr., Influence of Temperature and Section Size on Fatigue Crack Growth Behavior in Ni-Mo-V Alloy Steel, Engineering Fracture Mechanics, 2, 2 (1970).

C. A. Sciammarella and A. J. Durelli, Moiré Fringes as a Means of Analysing Strains, J. Eng. Mech. Div., Proc. of ASCE, Feb. (1961).

A. J. Durelli and V. J. Parks, Moiré Analysis of Strain, Prentice-Hall, Inc. Englewood Cliffs, N. J. (1970).

C. M. Hudson and J. T. Scardina, Effect of Stress Ratio on Fatigue-Crack Growth in 7075-T6 Aluminum Alloy Sheet, Eng. Fracture Mech., 1 (1969) 429.

W. G. Clark, Jr. and E. T. Wessel, Interpretation of the Fracture Behavior of 5436-H321 Aluminum with WOL Toughness Specimens, Westinghouse Research Lab. Scientific Paper 67-ID6-BTLFR-P4, Sept. (1967).

T. S. Kang and H. W. Liu, Fatigue Crack Tip Deformation and Fatigue Crack Propagation, NASA CR-120890. Feb. (1972).

J. L. Swedlow, M. L. Williams and W. H. Yang, Elasto-Plastic Stresses and Strains in Cracked Plates, Proc. First International Conf. on Fracture, Sendai, Japan 1 (1965) 259.

J. Kershaw and H. W. Liu, Electron Fractography and Fatigue Crack Propagation in 7075-T6 Aluminum Sheet, Int. Jour. of Fracture Mechanics, 7 (1971) 269–276.

G. T. Hahn, M. Sarrate and A. R. Rosenfield, Local Yielding Attending Fatigue Crack Growth, Metallurgical Transaction, 3, May (1972).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kang, T.S., Liu, H.W. Fatigue crack propagation and cyclic deformation at a crack tip. Int J Fract 10, 201–222 (1974). https://doi.org/10.1007/BF00113926

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00113926