Abstract

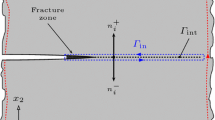

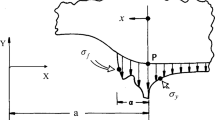

An equation is derived for the crack growth rate under creep conditions. In the model, the propagation of a grain boundary crack is controlled by the plastic growth of cavities located in the grain boundaries ahead of the crack. It is assumed that the cavities grow by power law creep in the elastic crack tip stress field. Hence, the stress dependence of the crack velocity is provided through the elastic stress intensity factor, i.e., dC/dt=BK p I .

The cavity spacing, λ, appears as an important factor in the coefficient,B ∝ λ−(p−2)/2. At large values of λ, corresponding to less severe creep damage in the grain boundaries, the above equation would predict very low values for the crack velocity. Under such conditions, we suggest that another mechanism, whose stress dependence is provided through the net section stress, becomes active, i.e., dC/dt=B′σ p′net . Since λ increases with decreasing applied stress, one should observe the σnet correlation at low stresses. The results of recent creep crack growth experiments which tend to support this hypothesis are presented.

Résumé

On dérive une équation décrivant la vitesse de propagation d'une fissure dans les conditions de fluage. Dans ce modèle, la propagation d'une fissure aux frontières de grains est contrôlée par la croissance dans le domaine plastique de cavités situées aux frontières de grains en avant de la fissure.

On suppose que les cavités s'étendent dans le champ de contraintes élastiques situées à l'extrémité de la fissure en suivant une loi de fluage parabolique. Dès lors, la dépendance de la vitesse de la fissuration en fonction de la contrainte est fournie par un facteur d'intensité de contrainte élastique, c'est-à-dire dC/dt=BK p I .

L'espace entre les cavités, λ, apparaît être un facteur important dans les coefficientsB. Pour de grandes valeurs de λ, qui correspondent à un dommage moins sévère par fluage aux frontières des grains, l'équation ci-dessus permettrait de prédire des valeurs très faibles de la vitesse de fissuration.

Sous ces conditions, il est suggèré qu'un autre mécanisme, dont la dépendance de la contrainte est fournie par la contrainte agissant sur la section droite, devient plus actif; on a alors dC/dt=B′σ p′nette .

Comme λ augmente lorsque la contrainte appliquée diminue, on devrait observer une corrélation de σ nette à basses contraintes.

Les résultats d'essais de croissance de fissure sous des conditions de fluage effectués récemment tendent à supporter cette hypothèse et sont présentés.

Similar content being viewed by others

References

M. J. Siverns and A. T. Price, Nature, 228 (1970) 760.

C. B. Harrison and G. N. Sandor, Engineering fracture Mechanics, 3 (1971) 403.

M. J. Siverns and A. T. Price, International Journal of Fracture, 9 (1973) 199.

G. J. Neate and M. J. Siverns, “The Application of Fracture Mechanics to Creep Crack Growth,” ASME,Conference on Creep and Fatigue in Elevated Temperature Applications, Philadelphia, PA (1973).

L. A. James, International Journal of Fracture Mechanics, 8 (1972) 347.

E. G. Ellison and D. Walton, “Fatigue, Creep, and Cyclic Creep Crack Propagation in a 1Cr-Mo-V Steel,”Conference on Creep and Fatigue in Elevated Temperature Applications, Philadelphia, PA (1973).

R. Koterazawa, International Journal of Fracture, 11 (1975) 1060.

J. L. Kenyon, G. A. Webster, J. C. Radon, and C. E. Turner, “An Investigation of the Application of Fracture Mechanics to Creep Cracking,”Conference on Creep and Fatigue in Elevated Temperature Applications, Philadelphia, PA (1973).

S. Floreen, Metallurgical Transactions Act., 6A (1975) 1741.

R. D. Nicholson and C. L. Formby, International Journal of Fracture, 11 (1975) 595.

J. A. Williams and A. T. Price,Transactions of the ASME, Series H 97 (1975) 214.

J. T. Barnby, Engineering Fracture Mechanics, 7 (1975) 229.

N. J. Hoff, Quantum Applied Mathematics, 12 (1954) 49.

P. W. Davies and B. Wilshire, “Structural Processes in Creep,” Iron and Steel Institute (1961).

H. E. Evans and J. S. Waddington, Philosophical Magazine, 20 (1969) 1075.

D. Hull and D. E. Rimmer, Philosophical Magazine, 4 (1959) 673.

R. L. Player and G. Brinson, Journal Aust. Inst. Materials, 20 (1975) 226.

M. V. Speight and J. E. Harris, Met. Science Journal, 1 (1967) 83.

J. Weertman, Metallurgical Transactions, 5 (1974) 1793.

W. D. Nix, D. K. Matlock, and R. J. DiMelfi, Acta Metallurgica, in press.

J. Finnie and W. R. Heller,Creep of Engineering Materials, McGraw Hill (1959) 168.

J. A. H. Hult, Creep in Engineering Structures, Blaisdell, London (1966) 86.

K. Hellan, International Journal Mech. Science 17 (1975) 369–374.

D. S. Wilkinson and M. F. Ashby,Pressure Sintering by Power Law Creep, Cambridge University Report # CUID/C-Mats/TR.22 (1975).

E. S. Machlin, Transactions Met. Society AIME, 206 (1956) 106.

R. P. Skelton, Philosophical Magazine, 15 (1967) 405.

A. F. Rowcliffe, Journal of Nuclear Materials, 15 (1966) 60.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Dimelfi, R.J., Nix, W.D. The stress dependence of the crack growth rate during creep. Int J Fract 13, 341–348 (1977). https://doi.org/10.1007/BF00040148

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00040148