Abstract

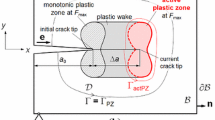

Crack closure is analyzed using an energy approach whereby it is shown that crack closure does not completely shield the input mechanical energy to the crack tip at a load below the crack opening load P op if the compliance below P op is non-zero. An equivalent shielding stress intensity range is defined by the energy release rate against crack closure. From this energy standpoint, the true effective stress intensity range should be defined as ΔK eff=K max−χK op, where χ is the shielding factor. The conventional definition (ΔK eff=K max−K op) is equivalent to the new definition only when the compliance below P op is zero such that χ=1, i.e., for a fully closed crack. The corrected ΔK eff is found to be effective in correlating fatigue crack growth rates (FCGRs) generated in 8090-T8771 aluminum-lithium alloy with and without crack closure. In contrast, the conventional ΔK eff fails to reconcile the FCGR data within an acceptable scatter band.

Similar content being viewed by others

References

W. Elber, Engineering Fracture Mechanics 2 (1970) 37–45.

W. Elber, ASTM STP 486 (1970) 230–241.

R.S. Vecchio, J.S. Crompton and R.W. Hertzberg, International Journal of Fracture 31 (1986) R29-R33.

R.W. Hertzberg, C.H. Newton and R. Jaccard, ASTM STP 982 (1988) 139–148.

R. Murakami, Y-H Kim and W.G. Ferguson, Fatigue and Fracture of Engineering Materials and Structures 14 (1991) 741–748.

B.K. Parida and T. Nicholas, International Journal of Fracture 52 (1991) R51-R54.

R.E. Garz and M.N. James, International Journal of Fatigue 11 (1989) 437–440.

S.A. Seetharam and P.K. Dash, International Journal of Fracture 53 (1992) R53-R58.

N. Louat, K. Sadanada, M. Duesbery and A.K. Vasudevan, Metallurgical Transactions A 24 (1993) 2225–2232.

S. Suresh and R.O. Ritchie, in Fatigue Crack Growth Threshold Concepts, D. Davidson and S. Suresh (eds.) The Metallurgical Society of AIME (1984) 227–261.

G.R. Irwin and J.E. Kies, Welding Journal 33 (1954) 193–198.

J.C. Newman, Jr., ASTM STP 637 (1977) 56–80.

M.D. Raizenne, An MTS Basic 770 Computer Program for Automated Fatigue Crack Growth Rate Testing, NRC-LTR-ST 1538, National Research Council of Canada (1986).

K.T. Venkateswara Rao, W. Wu and R.O. Ritchie, Metallurgical Transactions A 19A (1988) 563–568.

D.A. Hull, The Effect of Constant and Variable Amplitude Loading on Aluminum-Lithium Fatigue Crack Growth, Crack Deflection and Surface Roughness, IAR-CR-26, National Research Council of Canada, Ottawa (1994).

X.J. Wu, W. Wallace, A.K. Koul and M.D. Raizanne, Metallurgical Transactions A (1995) in press.

X.J. Wu, W. Wallace and A.K. Koul, Fatigue and Fracture of Engineering Structures and Materials 18 (1995) 833–845.

Author information

Authors and Affiliations

Additional information

The Canadian Government's right to retain a non-exclusive, royalty-free licence in and to any copyright is acknowledged.

Rights and permissions

About this article

Cite this article

Wu, X.J. An energy approach to crack closure. Int J Fract 73, 263–272 (1995). https://doi.org/10.1007/BF00037647

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00037647