Abstract

A compact model II fracture specimen was previously analyzed and employed to determine the mode II fracture toughness K IIc , of perspex. In employing this specimen for a more ductile material such as aluminium, it was observed that the load vs. crack sliding displacement record becomes nonlinear for small loads. Thus, concepts of linear elastic fracture mechanics cannot be employed. To this end, the specimen was calibrated for J-integral testing, so that J IIc mesurements can be performed.

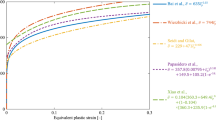

In this study, mode I and II tests are carried out on an aircraft aluminium alloy, AI 7075-T7351. First, standard K Ic tests are performed leading to a value of 27.9 15-1 which would be equivalent to a J Ic of 10.7 kN/m. Then standard J Ic tests are carried out on this material with specimen thicknesses, of 5, 7.5 and 9.9 mm, leading to an average J Ic value of 10.5 kN/m. Methods for J II testing are proposed; a series of specimens of six thicknesses between 5 and 16 mm are employed for testing. An average J IIc value was found to be 40.2 kN/m which yields a K IIc value of 54.1 15-2. Thus, K IIc is seen to be approximately twice that of K Ic for this material.

Similar content being viewed by others

References

L. Banks-Sills and M. Arcan, in Fracture Mechanics: Seventeenth Volume, ASTM-STP 905, American Society for Testing and Materials, Philadelphia (1986) 347–363.

L. Banks-Sills and D. Sherman, International Journal of Fracture 46 (1990) 105–122.

J.R. Rice, P.C. Paris and J.M. Merkle, in Progress in Flaw Growth and Fracture Toughness Testing, ASTM-STP 536, American Society for Testing and Materials, Philadelphia (1973) 231–245.

H. Ernst, P.C. Paris, M. Rossow and J.W. Hutchinson in Fracture Mechanics, ASTM-STP 677, American Society for Testing and Materials, Philadelphia (1979) 581–599.

C.E. Turner, in Fracture Mechanics, Twelfth Conference, ASTM-STP 700, American Society for Testing and Materials, Philadelphia (1980) 314–337.

“Standard Test Method for Plane Strain Fracture Toughness of Metallic Materials”, E 399-83, 1986 Annual Book of ASTM Standards, Vol. 03.01, American Society for Testing and Materials, Philadelphia (1986), 522–557.

“Standard Test Method for J Ic , A Measure of Fracture Toughness”, E 813-81, 1986 Annual Book of ASTM Standards, Vol. 03.01, American Society for Testing and Materials, Philadelphia (1986) 768–786.

J.R. Rice, in Fatigue Crack Propagation, ASTM-STP 415, American Society for Testing and Materials, Philadelphia (1967) 247–311.

D.C. Leigh, Nonlinear Continuum Mechanics, McGraw-Hill Book Company, New York (1968) 184.

R.M. McMeeking, Journal of the Mechanics and Physics of Solids 25 (1977) 357–381.

“Standard Practice for Plane Strain Fracture Toughness Testing of Aluminium Alloys”, B 645-84, 1986 Annual Book of ASTM Standards, Vol. 03.01, American Society for Testing and Materials, Philadelphia (1986) 97–104.

C.A. Griffis and G.R. Yoder, Journal of Engineering Materials and Technology 98 (1976) 152–158.

F. Erdogan and G.C. Sih, Journal of Basic Engineering 85 (1963) 519–527.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Banks-Sills, L., Sherman, D. J II fracture testing of a plastically deforming material. Int J Fract 50, 15–26 (1991). https://doi.org/10.1007/BF00035166

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00035166