Abstract

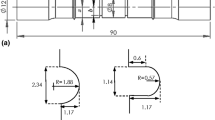

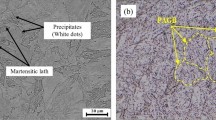

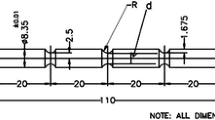

Notched tubular components of a ferritic oxide-dispersion-strengthened material, MA 956, were subjected to multiaxial creep loading at 1100°C by applying a constant internal pressure. The components proved to be extremely insensitive to circumferential notches of up to 80 percent of the wall thickness due to the high axial creep rupture strength of this material. However, the components were sensitive to both externally and internally axially aligned notches, and displayed similar stress rupture behaviour but consistently longer rupture lives than plane components at the same ligament stress level. Failure was found to be due to strain controlled cavitation in the ligament rather than as a consequence of creep crack growth from the notch. A direct current/potential drop method was shown to provide a reasonable indication of the development of cavitation in these tests. It is shown that the low ductility failure of notched MA 956 components is best described by a creep fracture mechanism rather than by fracture mechanics.

Similar content being viewed by others

References

J.D. Whittenberger, Tensile and creep properties of the experimental oxide dispersion strengthened iron-base sheet alloy MA 956E at 1365K Metallurgical Transactions A 9A (1978) 101–110.

M. Rees, J.D. Parker and R.C. Hurst, Creep of advanced ferritic oxide dispersion strengthened alloys for high temperature tubular heat exchangers. In D. Coutsouradis et al. (eds) Materials for Advanced Power Engineering 1994. Kluwer Academic Publishers (1994) II pp. 1573–1582.

M. Rees, J.C. Healy, R.C. Hurst and J.D. Parker, Creep Behaviour of Candidate Tubular Ferritic Oxide-Dispersion-Strengthened Heat Exchanger Components. In the proceedings of the Sixth International Conference on Creep and Fatigue, 15–17 April, 1996, London, UK, pp. 153–163. Published by Mechanical Engineering Publications Limited, 1996.

M. Rees, J.C. Healy, R.C. Hurst and J.D. Parker, Uniaxial and Multiaxial Creep Behaviour of a Tubular Ferritic Oxide Dispersion Strengthened Alloy at 1100°C. Submitted to Materials at High Temperatures.

G.A. Webster, Crack growth at high temperature. In Wilshire and Owen (eds.) Engineering Approaches to High Temperature Design Pineridge Press, U.K. (1983) pp. 1–55.

C.P. Hunter, Creep and creep crack growth in alloy 800H tubes at 800°C, Ph. D. thesis, University of Dublin, Ireland (1990).

A code of practice for internal pressure testing of tubular components at elevated temperatures, pub. by NPL, UK (1989).

R.A. Ainsworth and M.C. Coleman, Example of an application of an assessment procedure for defects in plant operating in the creep range. Fatigue and Fracture of Engineering Materials and Structures 10 (1987) 129–140.

M. Rees, The suitability of ferritic oxide dispersion strengthened tubular components for heat exchanger applications, Ph. D. thesis, University of Swansea, Wales (1995).

J.F. Kiefner, W.A. Maxey, R.J. Eiber and A.R. Duffy, Failure stress levels in pressurized cylinders. In Progress in Flaw Growth and Failure Toughness Testing ASTM STP 536 Philadelphia, Pa. (1973) pp. 161–481.

G.G. Chell, A Computer Program for Assessing Defects in Spheres and Shells, Nuclear Electric report no. TPRD/L/MT/0237/M84 ADISC.

G.G. Chell, Private Communication.

D.J.F. Ewing, The Plastic Collapse of a Thin-Walled Pressurised Pipe with an Axial Crack, CEGB report no. TPRD/L/2566/N83 (1983).

R.G. Sim, Evaluation of reference parameters for structures subject to creep Journal of the Mechanical Engineering Science 13 (1971) 47–50.

I.S. Raju and J.C. Newman, Stress-intensity factors for internal surface cracks in cylindrical pressure vessels Journal of Pressure Vessel Technology 104 (1982) 293–298.

S. Floreen, The creep fracture of wrought nickel-base alloys by a fracture mechanics approach Metallurgical Transactions A 6 (1975) 1741–1749.

M.J. Siverns and A.T. Price, Crack propagation under creep conditions in a quenched 2.25 Cr-1 Mo steel International Journal of Fracture 9 (1973) 199–207.

R.A. Ainsworth, G.G. Chell, M.C. Coleman, I.W. Goodall, D.J. Gooch, J.R. Haigh, S.T. Kimmins and G.J. Neate, CEGB assessment procedure for defects in plant operating in the creep range Fatigue and Fracture of Engineering Materials and Structures 10 (1987) 115–127.

K.M. Nikbin, D.J. Smith, and G.A. Webster, Influence of creep ductility and state of stress on creep crack growth. In D.A. Woodford and J.R. Whitehead (eds) Advances in Life Prediction Methods at Elevated Temperatures ASME, New York (1983) pp. 249–258.

D.R. Hayhurst, P.R. Dimmer and C.J. Morrison, Development of continuum damage in the creep rupture of notched bars Philosophical Transactions of the Royal Society London A 311 (1984) 103–129.

M.S. Loveday and B.F. Dyson, Creep deformation and cavitation damage in Nimonic 80A under a triaxial tensile stress. In K.J. Miller and R.F. Smith (eds) Mechanical Behaviour of Materials — III, 2 Pergamon, UK (1980) pp. 213–222.

R.D. Nicholson and C.L. Formby, Validity of various fracture-mechanics methods at creep temperatures International Journal of Fracture 20 (1975) 595–604.

A. Saxena, T. Hollstein, G.A. Webster and T. Yokobori, Intercomparison of creep crack growth data. In M.S. Loveday and T.B. Gibbons (eds) Harmonisation of Testing Practice for High Temperature Materials, Elsevier Applied Science, UK (1992) pp. 221–240.

K. Sadananda and P. Shahinian, Review of the fracture mechanics approach to creep crack growth in structural alloys Engineering Fracture Mechanics 15 (1981) 327–342.

H. Riedel, Fracture at High Temperatures, Springer-Verlag, 1987.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rees, M., Healy, J.C., Hurst, R.C. et al. Assessment of notched tubular ferritic oxide-dispersion-strengthened components subjected to multiaxial creep loading at 1100°C. Int J Fract 82, 115–129 (1996). https://doi.org/10.1007/BF00034659

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00034659