Abstract

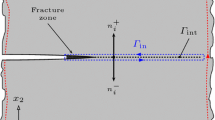

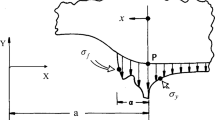

Two different constitutive models are employed to describe creep crack growth under small-scale creep conditions theoretically. The first model combines elastic/nonlinear viscous deformation fields (% MathType!MTEF!2!1!+-% feaafiart1ev1aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn% hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr% 4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq-Jc9% vqaqpepm0xbba9pwe9Q8fs0-yqaqpepae9pg0FirpepeKkFr0xfr-x% fr-xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGafqyTduMbai% aacqGH9aqpcuaHdpWCgaGaaiaac+cacaWGfbGaey4kaSIaamyqaiab% eo8aZnaaCaaaleqabaGaamOBaaaaaaa!4077!\[\dot \varepsilon = \dot \sigma /E + A\sigma ^n \]) with a critical-strain criterion, % MathType!MTEF!2!1!+-% feaafiart1ev1aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn% hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr% 4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq-Jc9% vqaqpepm0xbba9pwe9Q8fs0-yqaqpepae9pg0FirpepeKkFr0xfr-x% fr-xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeqyTduMaey% ypa0JaeqyTdu2aaSbaaSqaaiaadogaaeqaaaaa!3B55!\[\varepsilon = \varepsilon _c \], to be satisfied at a structural distance x c ahead of the crack. The deformation fields are characterized by three singular fields — the remote elastic field, the HRR field in the creep zone, if one exists, and the Hui-Riedel (HR) field near the growing crack tip. At small stress intensity factors, crack growth is found to become irregular and to tend to instabilities. This is a consequence of the properties of the HR field.

The second model is based on continuum damage mechanics. Creep strain rates are modified by a Kachanov-type denominator, % MathType!MTEF!2!1!+-% feaafiart1ev1aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn% hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr% 4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq-Jc9% vqaqpepm0xbba9pwe9Q8fs0-yqaqpepae9pg0FirpepeKkFr0xfr-x% fr-xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGafqyTduMbai% aacqGH9aqpcuaHdpWCgaGaaiaac+cacaWGfbGaey4kaSIaamyqaiab% eo8aZnaaCaaaleqabaGaamOBaaaakiaac+cacaGGOaGaaGymaiabgk% HiTiabeM8a3jaacMcadaahaaWcbeqaaiaad6gaaaaaaa!4722!\[\dot \varepsilon = \dot \sigma /E + A\sigma ^n /(1 - \omega )^n \], where ω is a damage parameter which obeys a second differential equation in time. Solutions of these constitutive equations for crack geometries contain crack growth automatically, where ω=1. It could not finally be decided whether a solution of this model for steady-state crack growth exists, but if it exists, the growth rate must be % MathType!MTEF!2!1!+-% feaafiart1ev1aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn% hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr% 4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq-Jc9% vqaqpepm0xbba9pwe9Q8fs0-yqaqpepae9pg0FirpepeKkFr0xfr-x% fr-xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGabmyyayaaca% Gaaeiiaiabg2Hi1kaabccacaWGlbWaa0baaSqaaiaaigdaaeaacaaI% Yaaaaaaa!3C16!\[\dot a{\text{ }} \propto {\text{ }}K_1^2 \] for dimensional reasons in contrast to % MathType!MTEF!2!1!+-% feaafiart1ev1aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn% hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr% 4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq-Jc9% vqaqpepm0xbba9pwe9Q8fs0-yqaqpepae9pg0FirpepeKkFr0xfr-x% fr-xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGabmyyayaaca% Gaaeiiaiabg2Hi1kaabccacaWGlbWaa0baaSqaaiaadMeaaeaacaWG% Ubaaaaaa!3C60!\[\dot a{\text{ }} \propto {\text{ }}K_I^n \] in the first model. For non-steady growth, the crack tip and the process zone may either be contained within the creep zone or may grow outside the creep zone. Corresponding to these cases, two types of similarity solutions can be obtained, in which the crack length, the process zone size and the creep zone size increase smoothly as a function of time with no tendency to instabilities. This difference to the first model arises since the HR field is displaced by the process zone. Only for crack growth within the creep zone do the results of the two models coincide (apart from numerical factors) if the stress intensity factor is high enough % MathType!MTEF!2!1!+-% feaafiart1ev1aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn% hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr% 4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq-Jc9% vqaqpepm0xbba9pwe9Q8fs0-yqaqpepae9pg0FirpepeKkFr0xfr-x% fr-xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaaiikaiaadU% eadaWgaaWcbaGaaGymaaqabaGccuGH+aGpgaGhaiaabccacaWGfbGa% eqyTdu2aaSbaaSqaaiaadogaaeqaaOWaaOaaaeaacaWG4bWaaSbaaS% qaaiaadogaaeqaaaqabaGccaGGPaaaaa!4091!\[(K_1 \underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle\thicksim}$}}{ > } {\text{ }}E\varepsilon _c \sqrt {x_c } )\].

Résumé

On recourt à deux modèles constitutifs différents pour décrire la croissance théorique d'une fissure de fluage dans des conditions de micro-fluage. Le premier modèle est une combinaison des champs de déformation élastique et visqueuse non-linéaire et d'un critère de déformation critique, qui doit être satisfait à une certaine distance en avant de la fissure. Les champs de déformation sont caractérisés par trois champs singuliers: le champs élastique lointain, le champs HRR dans la zone de fluage, et le champ de Hui-Riedel (HR) au voisinage de l'extrémité de la fissure en croissance. Pour de faibles facteurs d'intensité de contraintes, on constate que la croissance de la fissure devient irrégulière et fait état d'instabilités. Ceci est une conséquence des propriétés du champ HR.

Le second modèle est basé sur la mécanique d'endommagement d'un milieu continu. Les vitesses de fluage sont modifiées par un dénominateur de type Kachanov, fonction d'un paramètre d'endommagement qui dépend du temps selon une équation différentielle du second ordre. Lorsque ce paramètre vaut l'unité, les solutions de ces équations constitutives relatives aux géométries de la fissure contiennent automatiquement leur propagation. On ne peut définitivement décider s'il existe une solution de ce modéle pour une fissure en croissance stable, mais, si elle existe, la vitesse de croissance doit être proportionnelle au carré de K I, et non à sa puissance n comme dans le premier modèle. Pour une croissance instable, l'extrémité de la fissure et la zone de détérioration peuvent être contenues dans la zone de fluage, ou peuvent croître en dehors de cette zone. Dans ces cas, deus solutions de similitude peuvent être proposées. Pour autant que le facteur d'intensité de contraintes soit suffisament grand, les deux modèles ne coïncident aux facteurs numériques près que si la croissance de la fissure s'effectue dans la zone où règne le processus décrit.

Similar content being viewed by others

References

H. Riedel, Fracture at High Temperatures, Springer-Verlag, Berlin-Heidelberg-New York (1987).

H. Riedel, in Fracture Mechanics: Perspectives and Directions, ASTM STP 1020 (R.P. Wei and D. Ganglolff, eds.) American Society for Testing and Materials (1989) 101–126.

K. Ohji, K. Ogura and S. Kubo, Preprint of Japanese Society of Mechanical Engineers, No. 640–11 (1974) 207 (in Japanese).

J.D. Landes and J.A. Begley, in Mechanics of Crack Growth, ASTM STP 590, American Society for Testing and Materials (1976) 128–148.

R. Koterazawa and T. Mori, Transactions ASME, Journal of Engineering Materials Technology 99 (1977) 298–305.

S. Taira, R. Ohtani and T. Kitamura, Transactions ASME, Journal of Engineering Materials Technology 101 (1979) 154–161.

K. Ohji, K. Ogura, S. Kubo and Y. Katada, in Proceedings of the International Conference on Engineering Aspects of Creep, Sheffield, Vol. 2, The Institution of Mechanical Engineers, London (1980) 9–16.

T. Hollstein and R. Kienzler, Journal of Strain Analysis 23 (1988) 87–96.

A. Saxena, in Fracture Mechanics: Seventeenth Volume, ASTM STP 905 (J.H. Underwood et al., eds.) American Society for Testing and Materials (1986) 185–201.

H. Riedel and V. Detampel, International Journal of Fracture 33 (1987) 239–262.

H. Riedel and W. Wagner, in Advances in Fracture Research '84 — Proceedings of ICF6, Vol. 3 (S.R. Valluri et al., eds.) Pergamon Press, Oxford (1984) 2199–2206.

H. Riedel and J.R. Rice, in Fracture Mechanics: Twelfth Conference, ASTM STP 700 (P.C. Paris, ed.), American Society for Testing and Materials (1980) 112–130.

K. Ohji, K. Ogura and S. Kubo, Japanese Society of Materials Science, Japan 29, No. 320 (1980) 465–471.

S. Kubo, K. Ohji and K. Ogura, Engineering Fracture Mechanics 11 (1979) 315–329.

H. Riedel, in Creep in Structures (A.R.S. Ponter and D.R. Hayhurst, eds.) Springer-Verlag, Berlin (1981) 504–519.

J.L. Bassani, in Creep and Fracture of Engineering Materials and Structures (B. Wilshire and D.R.J. Owen, eds.) Pineridge Press, Swansea (1981) 329–344.

D.S. Wilkinson and V. Vitek, Acta Metallurgica 30 (1982) 1723–1732.

C.Y. Hui and H. Riedel, International Journal of Fracture 17 (1981) 409–425.

C.Y. Hui, in Elastic-Plastic Fracture, Second Sypposium, Vol. I — Inelastic Crack Analysis, ASTM STP 803 (C.F. Shih and J.P. Gudas, eds.) American Society for Testing and Materials (1983) I-573–I-593.

H. Riedel and W. Wagner, in Advances in Fracture Research, Proceedings of ICF5, Vol. 2 (D. Francois et al., eds.) Pergamon Press, Oxford (1981) 683–688.

F.-H. Wu, J.L. Bassani and V. Vitek, Journal of Mechanics and Physics of Solids 34 (1986) 455–475.

J.L. Bassani, D.E. Hawk and F.-H. Wu, Crack Growth in Small-Scale Creep, in Third International Conference on Nonlinear Fracture Mechanics, ASTM STP, American Society for Testing and Materials, to appear.

D.R. Hayhurst, P.R. Brown and C.J. Morrison, Philosophical Transactions of the Royal Society London A 311 (1984) 131–158.

L.M. Kachanov, The Theory of Creep, English translation edited by A.J. Kennedy, Boston Spa, Wetherby (1960).

D.R. Hayhurst and F.A. Leckie, in Mechanical Behaviour of Materials, Proceedings of ICM4, Vol. 2 (J. Carlsson and N.G. Ohlson, eds.) Pergamon Press, Oxford (1984) 1195–1212.

H. Riedel, in Fundamentals of Deformation and Fracture (B.A. Bilby, K.J. Miller and J.R. Willis, eds.) Cambridge University Press, Cambridge (1985) 293–309.

J.L. Bassani and D.E. Hawk, in Proceedings of MECAMAT, International Seminar on High Temperature Fracture Mechanisms and Mechanics, Dourdan, France (P. Bensussan et al., eds.) Mecamat, Moissy-Cramayet (1987) 19–40.

J.L. Bassani and D.E. Hawk, International Journal of Fracture 42 (1990) 157–172.

V. Tvergaard, International Journal of Fracture 31 (1986) 183–209.

V. Tvergaard, International Journal of Fracture 42 (1990) 145–155.

F.Z. Li, A. Needleman and C.F. Shih, International Journal of Fracture 38 (1988) 241–273.

J.W. Hutchinson, Acta Metallurgica 31 (1983) 1079–1088.

J.R. Rice, in Fracture, An Advanced Treatise (H. Liebowits, ed.) Vol. 2, Academic Press, New York (1968) 191–311.

J.W. Hutchinson, Journal of the Mechanics and Physics of Solids 16 (1968) 13–31.

J.R. Rice and G.F. Rosengren, Journal of the Mechanics and Physics of Solids 16 (1968) 1–12.

C.F. Shih, Tables of the Hutchinson-Rice-Rosengren Singular Field Quantities, Brown University Report MRL E-147, Providence, RI (1983).

E.W. Hart, International Journal of Solids and Structures 16 (1980) 807–823.

J.L. Bassani and F.A. McClintock, International Journal of Solids and Structures 17 (1981) 479–492.

C.Y. Hui and K.-C. Wu, International Journal of Fracture 31 (1986) 3–16.

C.Y. Hui and V. Banthia, International Journal of Fracture 25 (1984) 53–67.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Riedel, H. Creep crack growth under small-scale creep conditions. Int J Fract 42, 173–188 (1990). https://doi.org/10.1007/BF00018385

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00018385