Abstract

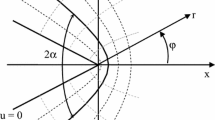

The slip-line field solutions for three-point bend specimens are reviewed for both deep and shallow notches. Plastic constraint factors, hydrostatic stress at the notch root and rotation constant to enable the crack upp opening displacement to be determined are given for a wide range of notch geometries. These values can be used in the fracture analysis of low strength metal specimens.

Résumé

On passe en revue les solutions décrivant les champs de bandes de glissement dans des éprouvettes de flexion sur trois appuis, dans les deux cas d'entailles peu profondes. On fournit pour une large gamme de géométries d'entaille les facteurs de retraint plastique, les contraintes hydrostatiques à la racine de l'entaille et la constante de rotation permettant de déterminer le COD à l'extrémité de la fissure. Ces valeurs peuvent être utilisées pour l'analyse de la rupture des éprouvettes de métaux à faible résistance.

Similar content being viewed by others

References

A.P. Green and B.B. Hundy, Journal of the Mechanics and Physics of Solids 4 (1956) 128–44.

A.P. Green, Journal of the Mechanics and Physics of Solids 4 (1956) 259–68.

J.M. Alexander and T.J. Komoly, Journal of the Mechanics and Physics of Solids 10 (1962) 265–75.

J.F. Knott, Journal of the Iron and Steel Institute 204 (1966) 104–11.

D.J.F. Ewing, Journal of the Mechanics and Physics of Solids 16 (1968) 205–13.

British Standards, Methods for crack opening displacement (COD) testing, BS 5762 (1979).

G. Matsoukas, B. Cotterell and Y.-W. Mai, International Journal of Fracture 26 (1984) R49-R53.

S.-X. Wu, Engineering Fracture Mechanics 18 (1983) 83–95.

L.-H. Lin, T.L. Anderson, R.de Wit and M.G. Dawes, International Journal of Fracture 20 (1982) R3-R7.

G.A. Clarke, W.R. Andrews, J.A. Begley, J.K. Donald, G.T. Embley, J.D. Landes, D.E. McCabe and J.H. Underwood, Journal of Testing and Evaluation 7 (1979) 49–56.

British Standard, Guidance on some methods for the derivation of acceptance levels for defects in fusion welded joints, PD 6493 (1980).

M.S. Kamath, The COD design curve: an assessment of validity using wide plate tests, Welding Institute Report 71/1978/E.

C.G. Chipperfield, Proceedings, Specialists Meeting in Elasto-Plastic Fracture Mechanics, OECD Nuclear Energy Agency Daresbury, Vol. 2, Paper 15.

B. Cotterell, Q.-F. Li, D.-Z. Zhang and Y.-W. Mai, Engineering Fracture Mechanics 24 (1986) 837–842.

G. Matsoukas, B. Cotterell and Y.-W. Mai, Engineering Fracture Mechanics 23 (1986) 661–665.

H.E. Thompson and J.F. Knott, Fracture Control of Engineering Structures. ECF 6 (1986).

P.W. Bridgman, Large Plastic Flow and Fracture, McGraw Hill, New York (1952).

K.E. Puttick, Philosophical Magazine, Ser. A, 4 (1959) 964–69.

F.A. McClintock, Journal of Applied Mechanics 35 (1968) 363.

G. Matsoukas, B. Cotterell and Y.-W. Mai, Engineering Fracture Mechanics 23 (1986) 661–65.

A.P. Green, Quarterly Journal of Mechanics and Applied Mathematics 6 (1953) 223–39.

A. Shindo and Y. Tomita, Bulletin of the Japan Society for Mechanical Engineering 15 (1972) 11–20.

G. Matsoukas, B. Cotterell and Y.-W. Mai, Journal of the Mechanics and Physics of Solids 34 (1986) 499–510.

D.J.F. Ewing, Doctoral Thesis, Cambridge University (1968).

D.J.F. Ewing, Journal of the Mechanics and Physics of Solids 15 (1967) 105–114.

I.F. Collins, Proceeding of the Royal Society, A303 (1968) 307.

P. Dewhurst and I.F. Collins, International Journal for Numerical Methods in Engineering 7 (1973) 357–378.

W. Johnson, R. Sowerby and R.D. Venter, Plane Strain Slip Line Fields for Metal Deformation Processes, Pergamon Press, Oxford (1982).

S.-X. Wu, Y.-W. Mai and B. Cotterell, International Journal of Mechanical Sciences 29 (1987) 557–564.

A. Shindo and Y. Tomita, Memoirs of the Faculty of Engineering, Tobe University, No. 20 (1974) 59–67.

J.F.W. Bishop, Journal of the Mechanics of Physics of Solids 2 (1953) 43–53.

NAG Fortran library routine document-CO5MBF.

ASTM Standard test for J 1c a measure of fracture toughness, E813-81.

British Standards, Methods for notched bar tests, The Charpy V-notch impact test on metals, BS 131: Part 2 (1972).

J.N. Robinson and A.S. Tetelman, International ofurnal of Fracture 11 (1975) 453–469.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wu, SX., Cotterell, B. & Mai, YW. Slip-line field solutions for three-point notch-bend specimens. Int J Fract 37, 13–29 (1988). https://doi.org/10.1007/BF00017820

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00017820