Abstract

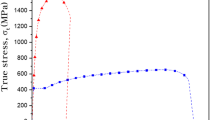

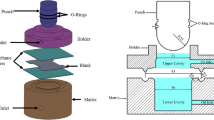

A new approach for predicting forming limit curves (FLCs) at elevated temperatures was proposed herein. FLCs are often used to predict failure and determine the optimal forming parameters of automotive parts. First, a graphical method based on a modified maximum force criterion was applied to estimate the FLCs of 22MnB5 boron steel sheets at room temperature using various hardening laws. Subsequently, the predicted FLC data at room temperature were compared with corresponding data obtained from Nakazima’s tests to obtain the best prediction. To estimate the FLC at elevated temperatures, tensile tests were conducted at various temperatures to determine the ratios of equivalent fracture strains between the corresponding elevated temperatures and room temperature. FLCs at elevated temperatures could be established based on obtained ratios. However, the predicted FLCs at elevated temperatures did not agree well with the corresponding FLC experimental data of Zhou et al. A new method was proposed herein to improve the prediction of FLCs at elevated temperatures. An FLC calculated at room temperature was utilized to predict the failure of Nakazima’s samples via finite element simulation. Based on the simulation results at room temperature, the mathematical relationships between the equivalent ductile fracture strain versus stress triaxiality and strain ratio were established and then combined with ratios between elevated and room temperatures to calculate the FLCs at different temperatures. The predicted FLCs at elevated temperatures agree well with the corresponding experimental FLC data.

Similar content being viewed by others

References

C. Robert, A. Delamézière, P. Dal Santo, J.L. Batoz, J. Mater. Process. Technol. 212 (2012) 1123–1131.

E. Fictorie, A.H. van den Boogaard, E.H. Atzema, Int. J. Mater. Form. 3 (2010) 1179–1182.

Z.M. Yue, H. Badreddine, T. Dang, K. Saanouni, A.E. Tekkaya, J. Mater. Process. Technol. 218 (2015) 80–88.

Z. Marciniak, K. Kuczyński, Int. J. Mech. Sci. 9 (1967) 609–620.

H.S. Son, Y.S. Kim, Int. J. Mech. Sci. 45 (2003) 1625–1643.

M.C. Butuc, J.J. Gracio, A. Barata da Rocha, J. Mater. Process. Technol. 142 (2003) 714–724.

P. Hora, L. Tong, B. Berisha, Int. J. Mater. Form. 6 (2013) 267–279.

D. Banabic, H. Aretz, L. Paraianu, P. Jurco, Modelling Simul. Mater. Sci. Eng. 13 (2005) 759–769.

N. Manopulo, P. Hora, P. Peters, M. Gorji, F. Barlat, Int. J. Plasticity 75 (2015) 189–203.

H. Aretz, Modelling Simul. Mater. Sci. Eng. 12 (2004) 677–692.

Q.T. Pham, B.H. Lee, K.C. Park, Y.S. Kim, Int. J. Mech. Sci. 140 (2018) 521–536.

Q.T. Pham, D.T. Nguyen, J.J. Kim, Y.S. Kim, Key Eng. Mater. 794 (2019) 55–62.

T.T. Luyen, Q.T. Pham, Y.S. Kim, D.T. Nguyen, J. Korean Soc. Precis. Eng. 36 (2019) 883–890.

N. Duc-Toan, K. Young-Suk, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 234 (2019) 189–203.

M. Merklein, J. Lecher, V. Gödel, S. Bruschi, A. Ghiotti, A. Turetta, Key Eng. Mater. 344 (2007) 79–86.

J. Zhou, Y. Mu, B. Wang, Int. J. Mech. Sci. 133 (2017) 457–468.

J. Lemaitre, J. Eng. Mater. Technol. 107 (1985) 83–89.

P. Hu, D. Shi, L. Ying, G. Shen, W. Liu, Mater. Des. 69 (2015) 141–152.

B.T. Tang, S. Bruschi, A. Ghiotti, P.F. Bariani, J. Mater. Process. Technol. 228 (2016) 76–87.

D.Y. Shi, L. Ying, P. Hu, J.D. Lu, X. Zhao, W.Q. Liu, AIP Conf. Proc. 1532, (2013) 406–413.

R.S. Lee, Y.K. Lin, T.W. Chien, Procedia Eng. 81 (2014) 1682–1688.

J. Min, J. Lin, J. Li, W. Bao, Comput. Mater. Sci. 49 (2010) 326–332.

H. Li, X. Wu, G. Li, J. Mater. Eng. Perform. 22 (2013) 2131–2140.

F.F. Li, M.W. Fu, J.P. Lin, X.N. Wang, Int. J. Adv. Manuf. Technol. 71 (2014) 297–306.

H. Liu, J. Cui, K. Jiang, G. Zhou, J. Mater. Eng. Perform. 25 (2016) 4894–4901.

S.P. Keeler, W.A. Backofen, Trans. ASM 56 (1963) 25–48.

S.S. Hecker, Sheet Met. Ind. 52 (1975) 671–676.

R. Hashemi, H. Mamusi, A. Masoumi, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 228 (2014) 1582–1591.

Z. Shao, Q. Bai, N. Li, J. Lin, Z. Shi, M. Stanton, D. Watson, T. Dean, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 232 (2018) 465–474.

Y.W. Lee, Fracture prediction in metal sheets, Massachusetts Institute of Technology, Cambridge, MA, USA, 2005.

R. Hill, Proc. R. Soc. Lond. A 193 (1948) 281–297.

H.W. Swift, J. Mech. Phys. Solids 1 (1952) 1–18.

P. Ludwik, Elemente der Technologischen Mechanik, J. Springer, 1909.

E. Voce, J. Inst. Metals 74 (1948) 537–562.

D. Li, G. Wang, H. Liu, Q. Chen, in: 2016 International Conference on Advanced Manufacture Technology and Industrial Application, DEStech Trans. Eng. Technol. Res. Shanghai, China, 2016, pp. 292–300.

D. Hibbit, B. Karlsson, P. Sorensen, ABAQUS/CAE user’s manual, Ver. 6.10.1. ABAQUS Inc, 2010.

Acknowledgements

This research is funded by Vietnam National Foundation for Science and Technology Development (NAFOSTED) under Grant Number 107.02-2019.300.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luyen, TT., Pham, QT., Mac, TB. et al. Graphical method based on modified maximum force criterion to indicate forming limit curves of 22MnB5 boron steel sheets at elevated temperatures. J. Iron Steel Res. Int. 28, 1009–1018 (2021). https://doi.org/10.1007/s42243-021-00567-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00567-5