Abstract

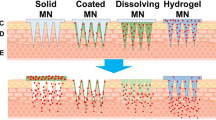

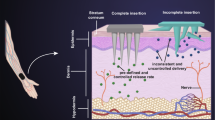

Transdermal drug delivery systems have overcome many limitations of other drug administration routes, such as injection pain and first-pass metabolism following oral route, although transdermal drug delivery systems are limited to drugs with low molecular weight. Hence, new emerging technology allowing high molecular weight drug delivery across the skin—known as ‘microneedles’—has been developed, which creates microchannels that facilitate drug delivery. In this report, drug-loaded degradable conic microneedles are modeled to characterize the degradation rate and drug release profile. Since a lot of data are available for polylactic acid-co-glycolic acid (PLGA) degradation in the literature, PLGA of various molecular weights—as a biodegradable polymer in the polyester family—is used for modeling and verification of the drug delivery in the microneedles. The main reaction occurring during polyester degradation is hydrolysis of steric bonds, leading to molecular weight reduction. The acid produced in the degradation has a catalytic effect on the reaction. Changes in water, acid and steric bond concentrations over time and for different radii of microneedles are investigated. To solve the partial and ordinary differential equations simultaneously, finite difference and Runge–Kutta methods are employed, respectively, with the aid of MATLAB. Correlation of the polymer degradation rate with its molecular weight and molecular weight changes versus time are illustrated. Also, drug diffusivity is related to matrix molecular weight. The molecular weight reduction and accumulative drug release within the system are predicted. In order to validate and assess the proposed model, data series of the hydrolytic degradation of aspirin (180.16 Da)- and albumin (66,000 Da)-loaded PLGA (1:1 molar ratio) are used for comparison. The proposed model is in good agreement with experimental data from the literature. Considering diffusion as the main phenomena and autocatalytic effects in the reaction, the drug release profile is predicted. Based on our results for a microneedle containing drug, we are able to estimate drug release rates before fabrication.

Similar content being viewed by others

References

Siepmann J, Ainaoui A, Vergnaud JM, Bodmeier R (1998) Calculation of the dimensions of drug-polymer devices based on diffusion parameters. J Pharm Sci 87:827–832

Siepmann J, Goepferich A (2001) Mathematical modeling of bioerodible, polymeric drug delivery systems. Adv Drug Deliv Rev 48:229–247

Arifin DY, Lee LY, Wang CH (2006) Mathematical modeling and simulation of drug release from microspheres: implications to drug delivery systems. Adv Drug Deliv Rev 58:1274–1325

Lin CC, Metters AT (2006) Hydrogels in controlled release formulations: network design and mathematical modeling. Adv Drug Deliv Rev 58:1379–1408

Higuchi T (1961) Physical chemical analysis of percutaneous absorption process from creams and ointments. J Soc Cosmet Chem 11:85–97

Higuchi T (1961) Rate of release of medicaments from ointment bases containing drugs in suspensions. J Pharm Sci 50:874–875

Zhou Y, Chu JS, Zhou T, Wu XY (2005) Modeling of dispersed-drug release from two-dimensional matrix tablets. Biomaterials 26:945–952

Frenning G, Brohede U, Stromme M (2005) Finite element analysis of the release of slowly dissolving drugs from cylindrical matrix systems. J Controll Release 107:320–329

Lemaire V, Belair J, Hildgen P (2003) Structural modeling of drug release from biodegradable porous matrices based on a combined diffusion/erosion process. Int J Pharm 258:95–107

Narasimhan B, Peppas NA (1997) Molecular analysis of drug delivery systems controlled by dissolution of the polymer carrier. J Pharm Sci 86:297–304

Shah UU, Roberts M, Orlu Gul M, Tuleu C, Beresford MW (2011) Needle-free and microneedle drug delivery in children: a case for disease-modifying antirheumatic drugs (DMARDs). Int J Pharm 416:1–11

Zhou CP, Liu YL, Wang HL, Zhang PX, Zhang JL (2010) Transdermal delivery of insulin using microneedle rollers in vivo. Int J Pharm 392:127–133

Mazur JE (2006) Mathematical models and the experimental analysis of behavior. J Exp Anal Behav 85:275–291

Siepmann FSJ (2008) Mathematical modeling of drug delivery. Int J Pharm 364:328–343

Pitt CG, Cha Y, Shah SS, Zhu KJ (1992) Blends of PVA and PGLA: control of the permeability and degradability of hydrogels by blending. J Controll Release 19:189–199

Antheunis H, van der Meer JC, de Geus M, Heise A, Koning CE (2010) Autocatalytic equation describing the change in molecular weight during hydrolytic degradation of aliphatic polyesters. Biomacromol 11:1118–1124

Lyu S, Schley J, Loy B, Lind D, Hobot C, Sparer R (2007) Kinetics and time-temperature equivalence of polymer degradation. Biomacromol 8:2301–2310

Siegel SJ, Kahn JB, Metzger K, Winey KI, Werner K, Dan N (2006) Effect of drug type on the degradation rate of PLGA matrices. Eur J Pharm Biopharm 64:287–293

Shah SS, Ch Y, Pitt CG (1992) Poly (glycolic acid-co-l-lactic acid): diffusion or degradation controlled drug delivery? J Controll Release 18:261–270

Antheunis H, van der Meer JC, de Geus M, Kingma W, Koning CE (2009) Improved mathematical model for the hydrolytic degradation of aliphatic polyesters. Macromolecules 42(7):2462–2471

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

Authors declare no conflict of interest.

Ethical approval

This paper does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Chavoshi, S., Rabiee, M., Rafizadeh, M. et al. Mathematical modeling of drug release from biodegradable polymeric microneedles. Bio-des. Manuf. 2, 96–107 (2019). https://doi.org/10.1007/s42242-019-00041-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42242-019-00041-y