Abstract

Sodium lignosulfonate/chitosan-glutaraldehyde adhesive (L/C-G) has potential in environment-friendly wood-based panel adhesive applications. However, the effect of sodium lignosulfonate on the bonding strength and chemical structure of L/C-G was not elucidated. Herein, the role of sodium lignosulfonate in L/C-G was studied in detail by characterizing the mechanical properties and water resistance of medium-density fiberboards (MDFs) prepared using L/C-G as adhesives. The functional groups, thermal stability, and crystalline structure of L/C-G with various mass ratios of sodium lignosulfonate to chitosan were also characterized by Fourier transform infrared spectroscopy, thermogravimetric analysis, and X-ray diffraction, respectively. The results show that an appropriate amount of sodium lignosulfonate in L/C-G was beneficial for its bonding strength, and the MDFs with 1:2 mass ratio of sodium lignosulfonate to chitosan showed superior mechanical properties and comparable water resistance with a commercial panel. Besides the reaction between sodium lignosulfonate and chitosan, guaiacyl units, or lateral chain of sodium lignosulfonate might also react with glutaraldehyde and result in C–O–C groups, helpful for the bonding strength of L/C-G.

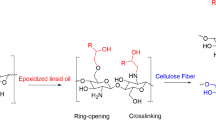

Graphical abstract

Similar content being viewed by others

References

Jiang W, Kumar A, Adamopoulos S (2018) Liquefaction of lignocellulosic materials and its applications in wood adhesives-a review. Ind Crop Prod 124:325–342. https://doi.org/10.1016/j.indcrop.2018.07.053

Pradyawong S, Li J, He Z, Sun XS, Wang D, Cheng HN, Klasson KT (2018) Blending cottonseed meal products with different protein contents for cost-effective wood adhesive performances. Ind Crop Prod 126:31–37. https://doi.org/10.1016/j.indcrop.2018.09.052

Nordqvist P, Johansson E, Khabbaz F, Malmström E (2013) Characterization of hydrolyzed or heat treated wheat gluten by SE-HPLC and 13C NMR: correlation with wood bonding performance. Ind Crop Prod 51:51–61. https://doi.org/10.1016/j.indcrop.2013.08.057

Xing J, Li T, Yu Y, Chen C, Chang J (2018) Development and characterization of a new bio-adhesive for wood using cassava starch and bio-oil. Int J Adhes Adhes 87:91–97. https://doi.org/10.1016/j.ijadhadh.2018.09.005

Despres A, Pizzi A, Vu C, Pasch H (2008) Formaldehyde-free aminoresin wood adhesives based on dimethoxyethanal. J Appl Polym Sci 110:3908–3916. https://doi.org/10.1002/app.28936

Chen G, Dong S, Zhao S, Li S, Chen Y (2019) Improving functional properties of zein film via compositing with chitosan and cold plasma treatment. Ind Crop Prod 129:318–326. https://doi.org/10.1016/j.indcrop.2018.11.072

Ji X, Li B, Yuan B, Guo M (2017) Preparation and characterizations of a chitosan-based medium-density fiberboard adhesive with high bonding strength and water resistance. Carbohydr Polym 176:273–280. https://doi.org/10.1016/j.carbpol.2017.08.100

Zhang C, Wang Z, Li Y, Yang Y, Ju X, He R (2019) The preparation and physiochemical characterization of rapeseed protein hydrolysate-chitosan composite films. Food Chem 272:694–701. https://doi.org/10.1016/j.foodchem.2018.08.097

Ji X, Guo M (2018) Preparation and properties of a chitosan-lignin wood adhesive. Int J Adhes Adhes 82:8–13. https://doi.org/10.1016/j.ijadhadh.2017.12.005

Ji X, Dong Y, Yuan B, Li B, Guo M (2018) Influence of glutaraldehyde on the performance of a lignosulfonate/chitosan-based medium density fiberboard adhesive. J Appl Polym Sci 135:45870. https://doi.org/10.1002/app.45870

Kai D, Tan MJ, Chee PL, Chua YK, Yap YL, Loh XJ (2016) Towards lignin-based functional materials in a sustainable world. Green Chem 18:1175–1200. https://doi.org/10.1039/C5GC02616D

Kalami S, Chen N, Borazjani H, Nejad M (2018) Comparative analysis of different lignins as phenol replacement in phenolic adhesive formulations. Ind Crop Prod 125:520–528. https://doi.org/10.1016/j.indcrop.2018.09.037

Gao S, Cheng Z, Zhou X, Liu Y, Chen R, Wang J, Wang C, Chu F, Xu F, Zhang D (2020) Unexpected role of amphiphilic lignosulfonate to improve the storage stability of urea formaldehyde resin and its application as adhesives. Int J Biol Macromol 161:755–762. https://doi.org/10.1016/j.ijbiomac.2020.06.135

Ji XD, Guo MH, Zhu L, Du W, Wang HB (2020) Synthesis mechanism of an environment-friendly sodium lignosulfonate/chitosan medium-density fiberboard adhesive and response of bonding performance to synthesis mechanism. Materials 13:5697. https://doi.org/10.3390/ma13245697

Li X, Li Y, Zhong Z, Wang D, Ratto JA, Sheng K, Sun XS (2009) Mechanical and water soaking properties of medium density fiberboard with wood fiber and soybean protein adhesive. Bioresour Technol 100:3556–3562. https://doi.org/10.1016/j.biortech.2009.02.048

Hu J-p, Guo M-h (2015) Influence of ammonium lignosulfonate on the mechanical and dimensional properties of wood fiber biocomposites reinforced with polylactic acid. Ind Crop Prod 78:48–57. https://doi.org/10.1016/j.indcrop.2015.09.075

Lopez-Suevos F, Riedl B (2003) Effects of Pinus pinaster bark extracts content on the cure properties of tannin-modified adhesives and on bonding of exterior grade MDF. J Adhes Sci Technol 17:1507–1522. https://doi.org/10.1163/156856103769207374

Li X, Wu Y, Cai Z, Winandy JE (2013) Primary properties of MDF using thermomechanical pulp made from oxalic acid pretreated rice straw particles. Ind Crop Prod 41:414–418. https://doi.org/10.1016/j.indcrop.2012.04.039

Segovia F, Blanchet P, Essoua GGE (2021) Potential of the crude glycerol and citric acid mixture as a binder in medium-density fiberboard manufacturing. Euro J Wood Wood Prod 79:1141–1151. https://doi.org/10.1007/s00107-021-01719-w

Bui TH, Lee W, Jeon S-B, Kim K-W, Lee Y (2020) Enhanced Gold(III) adsorption using glutaraldehyde-crosslinked chitosan beads: effect of crosslinking degree on adsorption selectivity, capacity, and mechanism. Sep Purif Technol 248:116989. https://doi.org/10.1016/j.seppur.2020.116989

Nawaz A, Li E, Irshad S, Hhm H, Liu J, Shahbaz HM, Ahmed W, Regenstein JM (2020) Improved effect of autoclave processing on size reduction chemical structure nutritional mechanical and in vitro digestibility properties of fish bone powder. Adv Powder Technol 31:2513–2520. https://doi.org/10.1016/j.apt.2020.04.015

Sarojini K, Krishnan H, Kanakam CC, Muthu S (2013) Synthesis, structural, spectroscopic studies NBO analysis NLO and HOMO–LUMO of 4-methyl-N-(3-nitrophenyl)benzene sulfonamide with experimental and theoretical approaches. Spectrochim Acta A 108:159–170. https://doi.org/10.1016/j.saa.2013.01.060

Kaushal AM, Chakraborti AK, Bansal AK (2008) FTIR studies on differential intermolecular association in crystalline and amorphous states of structurally related non-steroidal anti-inflammatory drugs. Mol Pharmaceut 5:937–945. https://doi.org/10.1021/mp800098d

Álvarez RMS, Cutín EH, Mack H-G, Romano RM, Della Védova CO (1997) Vibrational spectra of trifluoromethanesulfonyl isocyanate, CF3SO2NCO. J Raman Spectrosc 28:277–281

Sanden KW, Kohler A, Afseth NK, Böcker U, Rønning SB, Liland KH, Pedersen ME (2019) The use of Fourier-transform infrared spectroscopy to characterize connective tissue components in skeletal muscle of Atlantic cod (Gadus morhua L). J Biophotonics 12:e201800436. https://doi.org/10.1002/jbio.201800436

Shi R, Li B (2016) Synthesis and characterization of cross-linked starch/lignin film. Starch - Stärke 68:1224–1232. https://doi.org/10.1002/star.201500331

Li B, Lv W, Zhang Q, Wang T, Ma L (2014) Pyrolysis and catalytic pyrolysis of industrial lignins by TG-FTIR: Kinetics and products. J Anal Appl Pyrol 108:295–300. https://doi.org/10.1016/j.jaap.2014.04.002

Funding

The authors received financial support from the Natural Science Basic Research Plan in Shaanxi Province of China (2020JQ-260), the Ph. D. Start-up Fund of Northwest A&F University (2452019009), and the Open Fund of Jiangsu Key Laboratory of Biomass Energy and Materials in China (JSBEM201910).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Liu Chen and Bingnan Yuan contributed equally to this work.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, C., Yuan, B., Guo, M. et al. Effect of sodium lignosulfonate on bonding strength and chemical structure of a lignosulfonate/chitosan-glutaraldehyde medium-density fiberboard adhesive. Adv Compos Hybrid Mater 4, 1176–1184 (2021). https://doi.org/10.1007/s42114-021-00351-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00351-9