Abstract

In the present work, WC preforms with varied amounts of ZrC nanopowder (0–3.5 vol.%) were prepared using gel-casting base on nontoxic sodium alginate and then reactively infiltrated by molten Zr2Cu through displacive compensation of porosity method. The influence of ZrC nanopowder addition on the relative density, phase composition, microstructure, and properties of the final composites were investigated. The relative density, Vickers hardness, and flexural strength of the resulted composites prepared by reactive infiltration first increased and then decreased with increasing fraction of ZrC nanopowder in WC preforms. When the added fraction of ZrC nanopowder was 1.5 vol.%, the relative density, hardness, and flexural strength of the resulted composite reached their maximum values of about 97.3± 1%, 10.9± 0.3 GPa, and 503± 3 MPa, respectively. Fractography studies revealed that the fracture mode of composites was predominately intergranular. The W-ZrC composite was ablated by an oxyacetylene flame for 60 s. The mean value of mass and linear ablation rates of the composite were 2.1 ± 0.1 mg/s and 2.9 ± 0.3 μm/s, respectively. W-ZrC composites fabricated in complex and near net shapes at modest temperature and at ambient pressure by a reactive infiltration process can be utilized in aerospace applications.

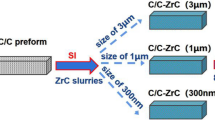

Graphical abstract

Similar content being viewed by others

References

Dickerson, M.B., Wurm, P.J., Schorr, J.R., Hoffman, W.P., Wapner, P.G., Sandhage, K.H.: Near net-shape, ultra-high melting, recession-resistant ZrC/W-based rocket nozzle liners via the displacive compensation of porosity (DCP) method. J. Mater. Sci. 39, 6005–6015 (2004)

Sciti, D., Guicciardi, S., Nygren, M.: Spark plasma sintering and mechanical behavior of ZrC-based composites. Scr. Mater. 59, 638–641 (2008)

Roosta, M., Baharvandi, H.: The comparison of W/cu and W/ZrC composites fabricated through hot-press. Int. J. Refract. Met. Hard Mater. 28, 587–592 (2010)

Roosta, M., Baharvandi, H.R., Abdizade, H.: The evaluation of W/ZrC composite fabricated through reaction sintering of two precursors: conventional ZrO2/WC and novel ZrSiO4/WC. Int. J. Refract. Met. Hard Mater. 29, 710–715 (2011)

Zhang, S., Wang, S., Li, W., Zhu, Y., Chen, Z.: Microstructure and properties of W–ZrC composites prepared by the displacive compensation of porosity (DCP) method. J. Alloys Compd. 509, 8327–8332 (2011)

Song, G.M., Wang, Y.J., Zhou, Y.: Elevated temperature ablation resistance and thermophysical properties of tungsten matrix composites reinforced with ZrC particles. J. Mater. Sci. 36, 4625–4631 (2001)

Song, G.M., Wang, Y.J., Zhou, Y.: The mechanical and thermophysical properties of ZrC/W composites at elevated temperature. Mater. Sci. Eng. A. 334, 223–232 (2002)

Najafzadeh Khoee, A.A., Habibolahzadeh, A., Qods, F., Baharvandi, H.: Microstructure and properties of DCP-derived W-ZrC composite using nontoxic sodium alginate to fabricate WC preform. J. Mater. Eng. Perform. 24, 1641–1648 (2015)

Zhao, Y.W., Wang, Y.J., Chen, L., Zhou, Y., Song, G.M., Li, J.P.: Microstructure and mechanical properties of ZrC\W matrix composite prepared by reactive infiltration at 1300 °C. Int. J. Refract. Met. Hard Mater. 37, 40–44 (2013)

Adabi, M., Amadeh, A.: Effect of infiltration parameters on composition of W–ZrC composites produced by displacive compensation of porosity (DCP) method. Int. J. Refract. Met. Hard Mater. 29, 31–37 (2011)

Zhang, T., Wang, Y., Zhoua, Y., Song, G.: Effect of ZrC particle size on microstructure and room temperature mechanical properties of ZrCp/W composites. Mater. Sci. Eng. A. 527, 4021–4027 (2010)

Zhang, S.C., Hilmas, G.E., Fahrenholtz, W.G.: Zirconium carbide–tungsten cermets prepared by in situ reaction sintering. J. Am. Ceram. Soc. 90, 1930–1933 (2007)

Dickerson, M.B., Snyder, R.L., Sandhage, K.H.: Dense, near-shaped, carbide/refractory metal composites at modest temperature by the displacive compensation of porosity (DCP) method. J. Am. Ceram. Soc. 85, 730–732 (2002)

Zhao, Y.W., Wanga, Y.J., Jina, X.Y., Jiaa, P., Chena, L., Zhoua, Y., Song, G.M., Li, J.P., Feng, Z.H.: Microstructure and properties of ZrC/W composite fabricated by reactive infiltration of Zr2Cu into WC/W preform. Mater. Chem. Phys. 153, 17–22 (2015)

Hammel, E.C., Ighodaro, O.L.R., Okoli, O.I.: Processing and properties of advanced porous ceramics: an application based review. Ceram. Int. 40, 15351–15370 (2014)

Yang, J., Yu, J., Huang, Y.: Recent developments in gelcasting of ceramics. J. Eur. Ceram. Soc. 31, 2569–2591 (2011)

Omatete, O.O., Janney, M.A., Strelow, R.A.: Gelcasting—a new ceramic forming process. Am. Ceram. Soc. Bull. 70, 1641–1649 (1991)

Najafzadeh Khoee, A.A., Habibolahzadeh, A., Qods, F., Baharvandi, H.: Fabrication of tungsten carbide foam through gel-casting process using nontoxic sodium alginate. Int. J. Refract. Met. Hard Mater. 43, 115–120 (2014)

Najafzadeh Khoee, A.A., Habibolahzadeh, A., Qods, F., Baharvandi, H.: Study on rheological behavior of WC slurry in gel-casting process and reactive infiltration of produced foam by molten Zr2Cu alloy. Int. J. Refract. Met. Hard Mater. 46, 30–34 (2014)

Xiaoyong, R., Zhijian, P., Chengbiao, W., Zhiqiang, F., Longhao, Q., Hezhuo, M.: Effect of ZrC nano-powder addition on the microstructure and mechanical properties of binderless tungsten carbide fabricated by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 48, 398–407 (2015)

Funding

The authors gratefully acknowledge the support from the Ministry of Education, Science, Research and Sport of the Slovak Republic (project VEGA1/0096/18).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• W-ZrC composites were fabricated by reactive infiltration of Zr2Cu into porous WC/nano ZrC preforms.

• XRD results and SEM micrographs, and elemental maps indicated the uniform distribution of phases (W and ZrC) and elements (W, Zr, and C).

• SEM micrographs of the fracture surfaces revealed two modes of fractures in the composites, transgranular and intergranular, however, the fracture mode is predominately intergranular.

• The fabricated composites had flexural strength and hardness in the ranges of 458–503 MPa and 9.2–10.9 GPa, respectively.

• The mean value of mass and linear ablation rates of the composite were 2.1 ± 0.1 mg/s and 2.9 ± 0.3 μm/s, respectively.

Rights and permissions

About this article

Cite this article

Najafzadehkhoee, A., Habibolahzadeh, A., Qods, F. et al. Effect of ZrC nanopowder addition in WC preforms on microstructure and properties of W–ZrC composites prepared by the displacive compensation of porosity (DCP) method. J Aust Ceram Soc 57, 515–523 (2021). https://doi.org/10.1007/s41779-020-00538-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-020-00538-1