Abstract

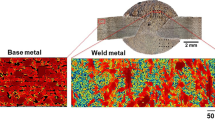

The speciation and atomic structures of corrosion products in Ni-based alloys could provide basic information for understanding the Te corrosion mechanism. In this paper, two-dimensional synchrotron-radiation-induced grazing incidence X-ray diffraction was used to characterize the corrosion products of a Ni–18%Cr binary alloy at temperatures from 600 to 1000 °C. The results showed that a film of CrTe is preferentially formed when Te reacts with the Ni-based alloy at low temperatures (below 900 °C), while CrTe and Ni3Te2 are formed at 900 °C. Moreover, at a temperature of 1000 °C, a solid solution is formed without any changes in the Ni–Cr substrate lattice parameters. Furthermore, X-ray absorption fine structure and wavelet transform analyses were used to investigate the atomic local structure of Te. The investigation indicated that Te atoms diffuse into the Ni–Cr substrate to form a substitutional Ni–Cr–Te solid solution at 1000 °C. Notably, based on a discussion of the thermodynamics of the chemical reaction process, CrTe is considered to be the most stable and prevalent corrosion product due to its comparatively lower Gibbs free energy of formation. These results demonstrate that the Ni–18%Cr alloy is capable of resisting the diffusion of Te atoms.

Similar content being viewed by others

References

R.C. Hill, J. Jagger, J.P. Holdren et al., Nuclear power as an energy source. Science 298, 1553–1554 (2016). https://doi.org/10.1126/science.298.5598.1549

S. Delpech, C. Cabet, C. Slim et al., Molten fluorides for nuclear applications. Mater. Today 13, 34–41 (2010). https://doi.org/10.1016/s1369-7021(10)70222-4

S. Volkov, A.O. Chuk, V. Azhazha et al., Corrosion stability of irradiated hastelloy-type alloys in molten NaF–ZrF4 mixture. J. New Mater. Electrochem. Syst. 9, 305–311 (2006). https://doi.org/10.1080/00223131.2014.854181

M.W. Rosenthal, P.N. Haubenreich, R.B. Briggs, The development status of molten-salt breeder reactors, ORNL/TM-4812, Oak Ridge, TN, USA, (1972). https://doi.org/10.2172/4622532

M.W. Rosenthal, R.B. Briggs, P.N. Haubenreich, Molten-salt reactor program, ORNL/TM-4832, Oak Ridge, TN, USA, (1972)

S. Mrowec, T. Walec, T. Werber, High-temperature sulfur corrosion of iron-chromium alloys. Oxid. Met. 1, 93–120 (1969). https://doi.org/10.1007/bf00609926

Y.Y. Jia, Z.F. Li, X.X. Ye et al., Effect of Cr contents on the diffusion behavior of Te in Ni-based alloy. J. Nucl. Mater. 497, 101–106 (2017). https://doi.org/10.1016/j.jnucmat.2017.10.062

Y.L. Wang, Q. Wang, H.J. Liu et al., Effects of the oxidants H2O and CrF3 on the corrosion of pure metals in molten (Li, Na, K)F. Corros. Sci. 103, 268–282 (2016). https://doi.org/10.1016/j.corsci.2015.11.032

T.Y. Yang, W. Wen, G.Z. Yin et al., Introduction of the X-ray diffraction beamline of SSRF. Nucl. Sci. Tech. 26, 020101 (2015). https://doi.org/10.13538/j.1001-8042/nst.26.020101

H.S. Yu, X.J. Wei, J. Li et al., The XAFS beamline of SSRF. Nucl. Sci. Tech. 26, 050102 (2015). https://doi.org/10.13538/j.1001-8042/nst.26.050102

B. Ravel, M. Newville, ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005). https://doi.org/10.1107/S0909049505012719

Y.Y. Jia, H.W. Chen, J. Qiu et al., Effect of temperature on diffusion behavior of Te into nickel. J. Nucl. Mater. 441, 372–379 (2013). https://doi.org/10.1016/j.jnucmat.2013.06.025

Z.M. Xia, H. Zhang, K.C. Shen et al., Wavelet analysis of extended X-ray absorption fine structure data: theory, application. Physica B 542, 12–19 (2018). https://doi.org/10.1016/j.physb.2018.04.039

L.D. Gulay, I.D. Olekseyuk, Crystal structures of the compounds Ni3Te2, Ni3−δTe2 (δ = 0.12) and Ni1.29Te. J. Alloys Compd. 376, 131–138 (2004). https://doi.org/10.1016/j.jallcom.2003.12.022

J. Barstad, F. Gronvold, E. Rost et al., On the tellurides of nickel. Acta Chem. Scand. 20, 2865–2879 (1966). https://doi.org/10.3891/acta.chem.scand.2865-2879

A.M. Azad, O.M. Sreedharan, Chromium activity in the Cr–Te system using a CaF, EMF method. J. Nucl. Mater. 167, 89–93 (1989). https://doi.org/10.1016/0022-3115(89)90428-5

G. Chattopadhyay, The Cr–Te (chromium–tellurium) system. J. Phase Equilib. 15, 431–440 (1994). https://doi.org/10.1007/bf02647574

K.T. Sasaki, T. Fujimura, R. Fujimura et al., The corrosion product of Cs–Te corrosive compound with 11Cr–ferritic/martensitic steel and 9Cr-oxide dispersion strengthened steel. J. Nucl. Mater. 460, 107–113 (2015). https://doi.org/10.1016/j.jnucmat.2015.02.011

F.Y. Ouyang, C.H. Chang, J.J. Kai, Long-term corrosion behaviors of Hastelloy-N and Hastelloy-B3 in moisture-containing molten FLiNaK salt environments. J. Nucl. Mater. 446, 81–89 (2014). https://doi.org/10.1016/j.jnucmat.2013.11.045

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Key Research and Development Program of China (No. 2016YFB0700404), National Natural Science Foundation of China (No. U1732267), National Natural Science Foundation of China (Nos. 51671122 and 51671154), Strategic Priority Research Program of the Chinese Academy of Sciences (No. XDA02004210), and Talent Development Fund of Shanghai (No. 201650).

Rights and permissions

About this article

Cite this article

Luo, M., Deng, SJ., Li, L. et al. XAFS and SRGI-XRD studies of the local structure of tellurium corrosion of Ni–18%Cr alloy. NUCL SCI TECH 30, 153 (2019). https://doi.org/10.1007/s41365-019-0673-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41365-019-0673-4