Abstract

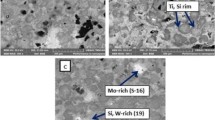

Hypereutectic Al–13.5Si alloy containing 1.47% of copper and 1.30% of magnesium was designed as a potential material for internal combustion engine pistons. The optical microscopy and scanning electron microscopy (SEM) revealed the fine dendrites of α-Al phase and significantly dispersed eutectics in as-cast specimens. Several intermetallic phases were observed indicating different crystallization velocities and alloy composition nonuniformities. The tensile testing and hardness measurements performed at room temperature have shown an excellent tensile strength and hardness of as-cast specimens, but low elongation due to a complex multiphase structure. The mechanical examinations at 250 °C and 300 °C have presented a decrease in tensile strength and an increase in elongation, while hardness was slightly changed. The fractographic analysis has shown the features of the brittle as well as ductile fracture. The areas of dimples and areas containing particles with smooth surfaces were detected. Electrochemical methods, Tafel linear polarization, cyclic voltammetry, chronoamperometric measurement and impedance spectroscopy were employed to determine the corrosion behavior of as-cast specimens in 0.5 M NaCl solution. The resistant oxide layer formed on the surface was not entirely consistent due to the appearance of intermetallic phases. SEM examinations of corroded samples did not discover severe pits on their surfaces.

Similar content being viewed by others

References

A.W. Orlowicz, M. Tupaj, M. Mróz, A. Trytek, Combustion engine cylinder liners made of Al–Si alloys. Arch. Foundry Eng. 15(2), 71–74 (2015)

R. Wieszala, J. Piątkowski, Selected tribological properties of A390.0 alloy. Arch. Foundry Eng. 17(4), 175–178 (2017)

M. Javidani, D. Larouche, Application of cast Al–Si alloys in internal combustion engine components. Int. Mater. Rev. 59(3), 132–158 (2014)

G.K. Sigworth, Int. Metalcast 2, 19 (2008). https://doi.org/10.1007/BF03355425

C.G. Shivaprasad, K. Aithal, S. Narendranath, V. Desai, P.G. Mukunda, Effect of combined grain refinement and modification on microstructure and mechanical properties of hypoeutectic, eutectic and hypereutectic Al–Si alloys. Int. J. Microstruct. Mater. Prop. 10(3/4), 274–284 (2015)

J. Jorstad, D. Apelian, Int. Metalcast 3, 13 (2009). https://doi.org/10.1007/BF03355450

A. Ahmed, M.S. Wahab, A.A. Raus, K. Kamarudin, Q. Bakhsh, D. Ali, Mechanical properties, material and design of the automobile piston: an ample review. Indian J. Sci. Technol. 9(36), 1–7 (2016)

J.O. Lima, C.R. Barbosa, I.A.B. Magno, J.M. Nascimento, A.S. Barros, M.C. Oliveira, F.A. Souza, O.L. Rocha, Microstructural evolution during unsteady-state horizontal solidification of Al–Si–Mg (356) alloy. Trans. Nonferrous Met. Soc. China 28(6), 1073–1083 (2018)

J.R. Davis, Alloying: Understanding the Basics, 1st edn. (Materials Park, ASM International, 2001), p. 392

F.C. Robles-Hernandez, J.M.H. Ramírez, R. Mackay, Al–Si Alloys: Automotive, Aeronautical, and Aerospace Applications (Springer, Switzerland, 2017), p. 187

J. Campbell, M. Tiryakioglu, Review of effect of P and Sr on modification and porosity development in Al–Si alloys. Mater. Sci. Technol. 26(3), 262–268 (2010)

M. Jolly, in Comprehensive Structural Integrity, ed. by J. Milne, R. Ritchie, B.L. Karihaloo (Elsevier, Amsterdam), p. 423

G. Sigworth, J. Campbell, J. Jorstad, Int. Metalcast 3, 65 (2009). https://doi.org/10.1007/BF03355442

B.D. Baliga, K.N. Mohandas, T.A. Kumar, Study of machinability and corrosion behaviour of Al–Si–Mg alloy treated with master alloys. Int. J. Eng. Sci. Inn. Technol. 4(3), 310–316 (2015)

M. Rejaeian, M. Karamouz, M. Emamy, M. Hajizamani, Effects of Be additions on microstructure, hardness and tensile properties of A380 aluminum alloys. Trans. Nonferrous Met. Soc. China 25(11), 3539–3545 (2015)

S. Vadim, Zolotorevsky, A. Nikolay, Belov, Michael, Glazoff, in Casting Aluminum Alloys, 1st edn. (Elsevier, Oxford, 2007), p. 329, 332, 335, 369, 496

M. Karamouz, M. Azarbarmas, M. Emamy, M. Alipour, Microstructure, hardness and tensile properties of A380 aluminum alloy with and without Li additions. Mater. Sci. Eng. A 582, 409–414 (2013)

R. Joseph, Davis, in Corrosion of Aluminum and Aluminum Alloys. (ASM International, Materials Park, 1999), pp. 38–42, 44

T.L. Su, S.S. Wang, L.C. Tsao, S.Y. Chang, T.H. Chuang, M.S. Yeh, Corrosion behaviors of Al–Si–Cu-based filler metals and 6061-T6 brazements. J. Mater. Eng. Perform. 11(2), 187–193 (2002)

W.R. Osorio, P.R. Goulart, A. Garcia, Effect of silicon content on microstructure and electrochemical behaviour of hypoeutectic Al–Si alloys. Mater. Lett. 62(3), 365–369 (2008)

Y. Wu, H. Liao, Corrosion behavior of extruded near eutectic Al–Si–Mg and 6063 alloys. J. Mater. Sci. Technol. 29(4), 380–386 (2013)

P. Chen, L. Liang, G. Luo, J. Zeng, Relationship between heat treatments and corrosion of Al–Si–Mg casting alloy. Adv. Mater. Res. 900, 96–99 (2014)

A. Wiengmoon, P. Sukchot, N. Tareelap, J.T.H. Pearce, T. Chairuangsri, Effects of T6 heat treatment with double solution treatment on microstructure, hardness and corrosion resistance of cast Al–Si–Cu alloys. Arc. Metall. Mater. 60(2), 881–886 (2015)

A.M. Cardinale, D. Macciò, G. Luciano, E. Canepa, P. Traverso, Thermal and corrosion behavior of as cast Al–Si alloys with rare earth elements. J. Alloys Compd. 695, 2180–2189 (2017)

J.G. Kaufman, E.L. Rooy, Aluminum Alloy Castings: Properties, Processes, and Applications (Materials Park, ASM International, 2004), p. 14

R.W. Revie, H.H. Uhlig, Corrosion and Corrosion Control—An Introduction to Corrosion Science and Engineering (Wiley, Hoboken, 2008), p. 394

F. Toptan, A.C. Alves, I. Kerti, E. Ariza, L.A. Rocha, Corrosion and tribocorrosion behavior of Al–Si–Cu–Mg alloy and its composites reinforced with B4C particles in 0.05 M NaCl solution. Wear 306(1–2), 27–35 (2013)

G. Svenningsen, J.E. Lein, A. Bjorgum, J.H. Nordlien, Y. Yu, K. Nisanciogly, Effect of low copper content and heat treatment on intergranular corrosion of model AlMgSi alloys. Corros. Sci. 48, 226–242 (2006)

A. Hossain, F. Gulshan, A.S.W. Kurny, Electrochemical corrosion behaviour of Ni-containing hypoeutectic Al–Si alloy. J. Electrochem. Sci. Eng. 5, 173–179 (2015)

H.O. Santos, F.M. Reis, C.T. Kunioshi, J.L. Rossi, I. Costa, Corrosion performance of Al–Si–Cu hypereutectic alloys in a synthetic condensed automotive solutions. Mater. Res. 8(2), 155–159 (2005)

S. Zor, M. Zeren, H. Ozkazanc, E. Karakulak, Effect of Cu content on the corrosion of Al–Si eutectic alloys in acidic solutions. Anti-Corros. Methods Mater. 57(4), 185–191 (2010)

R. Arrabal, B. Mingo, A. Pardo, M. Mohedano, E. Matykina, I. Rodrigues, Pitting corrosion of rheocast A356 aluminium alloy in 3.5 wt% NaCl. Corros. Sci. 73, 342–355 (2013)

R.A.M. Anaee, Study of Corrosion Behavior of Al-Si-Cu/WC Composites in 0.1 N NaOH. JKSUS 26(1), 55–65 (2015)

M.V. Rendón, J.A. Calderón, Evaluation of the corrosion behavior of the Al-356 alloy in NaCl solutions. Quim. Nova 34(7), 1163–1166 (2011)

Y.H. Cho, H.-C. Lee, K.H. Oh, A.K. Dahle, Effect of strontium and phosphorus on eutectic Al–Si nucleation and formation of β-Al5FeSi in hypoeutectic Al–Si foundry alloys. Metall. Mater. Trans. A 39(10), 2435–2448 (2008)

K. Al–Helal, I.C. Stone, Z. Fan, Simultaneous primary Si refinement and eutectic modification in hypereutectic Al-Si alloys. Trans. Indian Inst. Met. 65(6), 663–667 (2012)

M. Tiryakioglu, V.J. Campbell, Guidelines for designing metal casting research: application to aluminium alloy casting. Int. J. Cast Met. Res. 20(1), 25–29 (2007)

Y. Sui, Q. Wang, G. Wang, T. Liu, Effects of Sr content on the microstructure and mechanical properties of cast Al–12Si–4Cu–2Ni–0.8Mg alloys. J. Alloys Compd. 622, 572-579 (2015)

S. Farahany, A. Ourdjini, H.R. Bakhsheshi-Rad, Microstructure, mechanical properties and corrosion behavior of Al–Si–Cu–Zn–X (X = Bi, Sb, Sr) die cast alloy. Trans. Nonferrous Met. Soc. China 26(1), 28–38 (2016)

C. Bidmeshki, V. Abouei, H. Saghafian, S.G. Shabestari, M.T. Noghani, Effect of Mn addition on Fe-rich intermetallics morphology and dry sliding wear investigation of hypereutectic Al-17.5%Si alloys. J. Mater. Res. Technol. 5(3), 250–258 (2016)

G.-H. Zhang, J.-X. Zhang, B.-C. Li, W. Cai, Characterization of tensile fracture in heavily alloyed Al–Si piston alloy. Prog. Nat. Sci-Mater. 21(5), 380–385 (2011)

C. Liang, Z.-H. Chen, Z.-Y. Huang, F.-Q. Zu, Optimizing microstructures and mechanical properties of hypereutectic Al–18%Si alloy via manipulating its parent liquid state. Mater. Sci. Eng. A 690, 387–392 (2017)

N. Idusuyi, O.O. Ajide, O.O. Oluwole, O.A. Arotiba, Electrochemical Impedance Study of an Al6063–12%SiC–Cr Composite Immersed in 3 wt% Sodium Chloride. Procedia Manufacturing 7, 413-419 (2017)

V. Guillaumin, G. Mankowski, Localized corrosion of 6056 T6 aluminium alloy in chloride media. Corros. Sci. 42, 105–125 (2000)

S. Gudic, L. Vrsalovic, M. Kliskic, I. Jerkovic, A. Radonic, M. Zekic, Corrosion Inhibition of AA 5052 aluminium alloy in NaCl solution by different types of honey. Int. J. Electrochem. Sci. 11, 998–1011 (2016)

F. Zeng, Z. Wei, J. Li, C. Li, X. Tan, Z. Zhang, Z. Zheng, Corrosion mechanism associated with Mg2Si and Si particles in Al–Mg–Si alloys. Trans. Nonferrous Met. Soc. China 21(12), 2559–2567 (2011)

R.A. Rodríguez-Diaz, J. Uruchurtu-Chavarín, A.M. Cotero-Villegas, S. Valdez, J.A. Juárez-Islas, Corrosion behavior of AlMgSi alloy in aqueous saline solution. Int. J. Electrochem. Sci. 10, 1792–1808 (2015)

G.R. Kramer, C.M. Mendez, A.E. Ares, Evaluation of corrosion resistance of aluminum-based alloys in bioethanol produced in misiones. Procedia Mater. Sci. 9, 341–349 (2015)

H.H. Hassan, K. Fahmy, Pitting corrosion of tin by acetate anion in acidic media. Int. J. Electrochem. Sci. 3, 29–43 (2008)

I.T.E. Fonseca, N. Lima, J.A. Rodrigues, M.I.S. Pereira, J.C.S. Salvador, M.G.S. Ferreira, Passivity breakdown of Al 2024-T3 alloy in chloride solutions: a test of the point defect model. Electrochem. Commun. 4(5), 353–357 (2002)

K. Magdic, V. Horvat-Radosevic, The role of electrochemical impedance spectroscopy in the characterization of electrodes and devices for energy conversion and storage. Kem. Ind. 62(3–4), 81–91 (2013) (in Croatian)

M.S. Kaiser, M.R. Qadir, S. Dutta, Electrochemical corrosion performance of commercially used aluminium engine block and piston in 0.1 M NaCl. J. Mech. Eng. 45(1), 48–52 (2015)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Scepanovic, J., Asanovic, V., Herenda, S. et al. Microstructural Characteristics, Mechanical Properties, Fracture Analysis and Corrosion Behavior of Hypereutectic Al–13.5Si Alloy. Inter Metalcast 13, 700–714 (2019). https://doi.org/10.1007/s40962-019-00315-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00315-2