Abstract

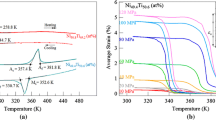

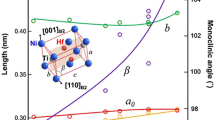

Loading path dependencies and control mode effects in polycrystalline shape memory NiTi were investigated using in situ neutron and synchrotron X-ray diffraction performed during mechanical cycling and thermal cycling at constant strain. Strain-controlled, isothermal, reverse loading (to ± 4%) and stress-controlled, isothermal, cyclic loading (to ± 400 MPa for up to ten cycles) at room temperature demonstrated that the preferred martensite variants selected correlated directly with the macroscopic uniaxial strain and did not correlate with the compressive or tensile state of stress. During cyclic loading (up to ten cycles), no significant cycle-to-cycle evolution of the variant microstructure corresponding to a given strain was observed, despite changes in the slope of the stress–strain response with each cycle. Additionally, thermal cycling (to above and below the phase transformation) under constant strain (up to 2% tensile strain) showed that the martensite variant microstructure correlated directly with strain and did not evolve following thermal cycling, despite relaxation of stress in both martensite and austenite phases. Results are presented in the context of variant reorientation and detwinning processes in martensitic NiTi, the fundamental thermoelastic nature of such processes and the ability of the variant microstructure to accommodate irreversible deformation processes.

Similar content being viewed by others

References

Bhattacharya K (ed) (2003) Microstructure of martensite: why it forms and how it gives rise to the shape-memory effect?. Oxford University Press, New York

Miyazaki S, Otsuka K, Wayman CM (1989) The shape memory mechanism associated with the martensitic transformation in TiNi alloys—I. Self-accommodation. Acta Metall 37(7):1873–1884

Otsuka K, Ren X (2005) Physical metallurgy of Ti-Ni-based shape memory alloys. Prog Mater Sci 50(5):511–678

Yamauchi K, Ohkata I, Tsuchiya K, Miyazaki S (eds) (2011) Shape memory and superelastic alloys: technologies and applications. Woodhead Publishing, Oxford

Saleeb AF, Padula SA II, Kumar A (2011) A multi-axial, multimechanism based constitutive model for the comprehensive representation of the evolutionary response of SMAs under general thermomechanical loading conditions. Int J Plast 27(5):655–687

Nicholson DE, Padula SA II, Benafan O, Vaidyanathan R (2017) Texture evolution during isothermal, isostrain and isobaric loading of polycrystalline shape memory NiTi. Appl Phys Lett 110(25):251903

Nicholson DE, Bass MA, Mabe JH, Benafan O, Padula SA, Vaidyanathan R (2016) Heating and loading paths to optimize the performance of trained shape memory alloy torsional actuators. ASME (2016), conference on smart materials, adaptive structures and intelligent systems. American Society of Mechanical Engineers, New York

Benafan O, Padula SA II, Noebe RD, Sisneros T, Vaidyanathan R (2012) Role of B19′ martensite deformation on the stability of NiTi two-way shape memory effect. J Appl Phys 112(9):093510

Stebner AP, Vogel SC, Noebe RD, Sisneros T, Clausen B, Brown DW, Garg A, Brinson LC (2013) Micromechanical quantification of elastic, twinning, and slip strain partitioning exhibited by polycrystalline, monoclinic nickel-titanium during large uniaxial deformations measured via in situ neutron diffraction. J Mech Phys Solids 61(11):2302–2330

Wagner MFX, Windl W (2008) Lattice stability, elastic constants and macroscopic moduli of NiTi martensites from first principles. Acta Mater 56(20):6232–6245

Qiu S, Clausen B, Padula SA II, Noebe RD, Vaidyanathan R (2011) On elastic moduli and elastic anisotropy in polycrystalline martensitic NiTi. Acta Mater 59(13):5055–5066

Stebner AP, Brown DW, Brinson LC (2013) Young’s modulus evolution and texture-based elastic–inelastic strain partitioning during large uniaxial deformations of monoclinic nickel–titanium. Acta Mater 61(6):1944–1966

Ezaz T, Sehitoglu H, Maier HJ (2011) Energetics of twinning in martensitic NiTi. Acta Mater 59(15):5893–5904

Xie ZL, Liu Y (2004) HRTEM study of 〈011〉 type II twin in NiTi shape memory alloy. Philos Mag 84(32):3497–3507

Xie ZL, Liu Y, Van Humbeeck J (1998) Microstructure of NiTi shape memory alloy due to tension–compression cyclic deformation. Acta Mater 46(6):1989–2000

Liu Y, Xie Z, Van Humbeeck J (1999) Cyclic deformation of NiTi shape memory alloys. Mater Sci Eng A 273–275(15):673–678

Nishida M, Ii S, Kitamura K, Furukawa T, Chiba A, Hara T, Hiraga K (1998) New deformation twinning mode of B19′ martensite in Ti-Ni shape memory alloy. Scr Mater 39(12):1749–1754

Benafan O, Noebe RD, Halsmer TJ, Padula SA II, Bigelow GS, Gaydosh DJ, Garg A (2016) Constant-strain thermal cycling of a Ni50.3Ti29.7Hf20 high-temperature shape memory alloy. Shape Mem Superelasticity 2(2):1–10

Benafan O, Noebe RD, Halsmer TJ (2016) Static rock splitters based on high temperature shape memory alloys for planetary explorations. Acta Astronaut 118:137–157

Benafan O, Padula SA II, Noebe RD, Brown DW, Clausen B, Vaidyanathan R (2013) An in situ neutron diffraction study of shape setting NiTi shape memory alloy. Acta Mater 61(10):3585

Qiu S, Krishnan VB, Padula SA, Noebe RD, Brown DW, Clausen B, Vaidyanathan R (2009) Measurement of the lattice plane strain and phase fraction evolution during heating and cooling in shape memory NiTi. Appl Phys Lett 95(14):141906

Padula SA, Qiu S, Gaydosh D, Noebe R, Bigelow G, Garg A, Vaidyanathan R (2012) Effect of upper-cycle temperature on the load-biased, strain-temperature response of NiTi. Metall Mater Trans A 43:4610–4621

Manchiraju S, Gaydosh D, Benafan O, Noebe R, Vaidyanathan R, Anderson PM (2011) Thermal cycling and isothermal deformation response of polycrystalline NiTi: simulations vs. experiment. Acta Mater 59(13):5238–5249

Bourke MAM, Dunand DC, Ustundag E (2002) SMARTS—a spectrometer for strain measurement in engineering materials. Appl Phys Lett 74:S1707

Von Dreele RB, Jorgensen JD, Windsor CG (1982) Rietveld refinement with spallation neutron powder diffraction data. J Appl Crystallogr 15:581–589

Larson AC, Von Dreele RB (2004) General Structure Analysis System (GSAS). Report LAUR 86-748. Los Alamos National Laboratory, New Mexico

Krishnan V, Manjeri RM, Clausen B, Brown D, Vaidyanathan R (2008) Analysis of neutron diffraction spectra acquired in situ during mechanical loading of shape memory NiTiFe at low temperatures. Mater Sci Eng A 481:3–10

Vaidyanathan R, Bourke MAM, Dunand DC (1999) Analysis of neutron diffraction spectra acquired in situ during stress-induced transformations in superelastic NiTi. J Appl Phys 86(6):3020–3029

Von Dreele RB (1997) Quantitative texture analysis by Rietveld refinement. J Appl Crystallogr 30:517–525

Wessel P, Smith WHF (1995) New verison of the generic mapping tools. EOS Trans Am Geophys Union 76(33):329

Benafan O, Garg A, Noebe RD, Bigelow GS, Padula SA, Gaydosh DJ, Schell N, Mabe JH, Vaidyanathan R (2014) Mechanical and functional behavior of a Ni-rich Ni 50.3 Ti 29.7 Hf 20 high temperature shape memory alloy. Intermetallics 50:94–107

Benafan O, Garg A, Noebe RD, Skorpenske HD, An K, Schell N (2017) Deformation characteristics of the intermetallic alloy 60NiTi. Intermetallics 82:40–52

Vaidyanathan R, Bourke MAM, Dunand DC (2001) Texture, strain, and phase-fraction measurements during mechanical cycling in superelastic NiTi. Metall Mater Trans A 32(13):777–786

Rathod CR, Clausen B, Bourke MAM, Vaidyanathan R (2006) Neutron diffraction investigation of hysteresis reduction and increase in linearity in the stress-strain response of superelastic NiTi. Appl Phys Lett 88(20):201919

Benafan O, Noebe RD, Padula SA II, Garg A, Clausen B, Vogel S, Vaidyanathan R (2013) Temperature dependent deformation of B2 austenite in a NiTi shape memory alloy. Int J Plast 51:103–121

Benafan O, Noebe RD, Padula SA II, Brown DW, Vogel S, Vaidyanathan R (2014) Thermomechanical cycling of a NiTi shape memory alloy-macroscopic response and microstructural evolution. Int J Plast 56:99–118

Otsuka K, Wayman CM (eds) (1999) Shape memory materials. Cambridge University Press, Cambridge

Ye B, Majumdar BS, Dutta I (2009) Texture development and strain hysteresis in a NiTi shape-memory alloy during thermal cycling under load. Acta Mater 57(8):2403–2417

Ye B, Majumdar BS, Dutta I (2007) Texture memory and strain-texture mapping in a NiTi shape memory alloy. Appl Phys Lett 91(6):061918

Saburi T, Nenno S (1981) Solid phase transformations. TMS-AIME, Warrendale

Acknowledgements

The authors would like to acknowledge funding from the NASA Fundamental Aeronautics Program., Supersonics Project (Grant No. NNX08AB51A) and Subsonic Fixed Wing Project (Grant No. NNX11AI57A). This work has benefited from the use of the Lujan Neutron Scattering Center at LANSCE, which was funded by the Office of Basic Energy Sciences (DOE). LANL is operated by Los Alamos National Security LLC under DOE under Contract No. DE-AC52-06NA25396. This work also benefitted from the use of the HEMS beamline at the German high-brilliance synchrotron radiation storage ring PETRA III at DESY. The authors thank T. Sisneros and D.W. Brown at LANL and N. Schell at DESY for technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nicholson, D.E., Benafan, O., Padula, S.A. et al. Loading Path and Control Mode Effects During Thermomechanical Cycling of Polycrystalline Shape Memory NiTi. Shap. Mem. Superelasticity 4, 143–157 (2018). https://doi.org/10.1007/s40830-017-0136-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-017-0136-x