Abstract

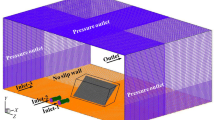

Over the last decades, significant improvements have been achieved in terms of noise reduction for jet engine aircraft. Nevertheless, jet noise remains one of the major sound sources from commercial aircraft, particularly during take-off. To develop strategies for jet noise reduction, it becomes paramount to understand the mechanisms of sound production and radiation from the experimental point of view. For this reason, researchers need high-quality noise data, obtained under proper conditions for both the acoustic and flow fields of scaled jets. This paper reports the development, validation and application of a new jet rig facility built at Federal University of Santa Catarina for investigations of jet noise. Issues relating to limited budget, deadline fulfillment and inner space restrictions, made the design and construction of the facility particularly difficult. Such drawbacks were overcome by designing carefully every system making up the whole facility, some of them based on CFD analyses, as well as by employing tailored solutions to some systems. Throughout the paper, the infrastructure of facility and its main systems are presented as well as major design requirements are discussed. Subsequently, the free-field qualification and the determination of acoustic far-field for the jet source, concerning the anechoic chamber, are described. With the aim of evaluating the acoustic performance of the facility, noise data were acquired for jet flows with Mach numbers from 0.3 to 0.9 and observer locations from 60 to 150 degrees. Additionally, hot-wire anemometry measurements were performed at different axial positions along the jet to illustrate the turbulent character of flows generated. Results of flow and noise measurements revealed an acoustically clean signature as well as turbulence properties in good agreement with data from other facilities. Finally, the paper outlines the underway research works at the mentioned facility and new directions for further work.

Similar content being viewed by others

References

Casalino D, Diozzi F, Sannino R, Paonessa A (2008) Aircraft noise reduction technologies: a bibliographic review. Aerosp Sci Technol 12:1–17. https://doi.org/10.1016/j.ast.2007.10.004

Powell CA, Fields JM (1995) Human response to aircraft noise. In: Hubbard HH (ed) Aeroacoustics of flight vehicles theory and practice, vol 2. Noise control. Aeroacoustic Society of America, Woodbury, pp 1–48

Finkle AL, Poppen JR (1948) Clinical effects of noise and mechanical vibrations of a turbojet engine on man. J Appl Physiol 1(3):183–204

Barbot B, Lavandier C, Chemineé P (2008) Perceptual representation of aircraft sounds. Appl Acoust 69:1003–1016. https://doi.org/10.1016/j.apacoust.2007.07.001

Callender WB (2004) An investigation of innovative technologies for reduction of jet noise in medium and high bypass turbofan engines. PhD Dissertation, University of Cincinnati

Astley RJ (2014) Can technology deliver acceptable levels of aircraft noise? In: Proceedings of internoise 2014, Melbourne, Australia

Campos LMBC (2006) On some recent advances in aeroacoustics. Int J Acoust Vib 11:27–45. https://doi.org/10.20855/ijav.2006.11.1190

Omais M et al (2008) Jet noise prediction using RANS CFD input. AIAA Paper 2008-2938

Karabasov SA et al (2008) Using large eddy simulation within an acoustic analogy approach for jet noise modelling. AIAA Paper 2008-2985

Ladeinde F et al. (2011) An integrated RANS-PSE-wave packet tool for the prediction of subsonic and supersonic jet noise. AIAA Paper 2011-2704

Massey SJ et al (2003) Computational and experimental flow field analyses of separate flow chevron nozzles and pylon interaction. AIAA Paper 2003-3212

Tanna HK, Dean PD, Burrin RH (1976) The generation and radiation of supersonic jet noise, part III, Turbulent mixing noise data. AFAPL-TR-76-65

Brown C, Bridges J (2006) Small hot jet acoustic rig validation. NASA/TM-214234

Colonius T, Lele SK (2004) Computational aeroacoustics: progress on nonlinear problems of sound generation. Prog Aerosp Sci 40:345–416. https://doi.org/10.1016/j.paerosci.2004.09.001

Dowling AP, Hynes TP (2004) Sound generation by turbulence. Eur J Mech B Fluids 23:491–500. https://doi.org/10.1016/j.euromechflu.2003.10.014

Jansson D, Mathew J, Hubner JP, Sheplak M, Cattafesta L (2002) Design and validation of an aeroacoustic anechoic test facility. AIAA Paper 2002-2466

Tinney CE, Hall A, Glauser MN, Ukeiley LS, Coughlin T (2004) Designing an anechoic chamber for the experimental study of high speed heated jets. AIAA Paper 2004-0010

Ponton MK, Seiner JM, Ukeiley LS, Jansen BJ (2001) A new anechoic chamber design for testing high-temperature jet flows. AIAA Paper 2001-2190

Ahuja KK (2003) Designing clean jet noise facilities and making accurate jet noise measurements. AIAA Paper 2003-0706

Hahn CB (2011) Design and validation of the new jet facility and anechoic chamber. MSc Dissertation, Ohio State University

Mathew J (2006) Design, fabrication, and characterization of an anechoic wind tunnel facility. PhD Dissertation, University of Florida

Duell E, Walter J, Arnette S, Yen J (2002) Recent advances in large-scale aeroacoustic wind tunnels. AIAA Paper 2002-2503

Joslin RD et al (2005) Synergism of flow and noise control technologies. Prog Aerosp Sci 41:363–417. https://doi.org/10.1016/j.paerosci.2005.07.002

Martens S (2002) Jet noise reduction technology development at GE aircraft engines. In: 22nd Congress of international council of the aeronautical sciences, UK

Herkes WH, Olsen RF, Uellenberg S (2006) The quiet technology demonstrator program: flight validation of airplane noise-reduction concepts. AIAA Paper 2006-2720

Nesbitt E, Mengle VG, Callender B, Czech M, Thomas R (2006) Flight test results for uniquely tailored propulsion-airframe aeroacoustic chevrons: community noise. AIAA Paper 2006-2438

Bennett GJ et al (2015) Aeroacoustics research in Europe: the CEAS-ASC report on 2013 highlights. J Sound Vib 340:39–60. https://doi.org/10.1016/j.jsv.2014.12.005

Detandt Y (2015) Aeroacoustics research in Europe: the CEAS-ASC report on 2014 highlights. J Sound Vib 357:107–127. https://doi.org/10.1016/j.jsv.2015.07.005

Saiyed NH, Mikkelsen KL, Bridges JE (2000) Acoustics and thrust of separate-flow exhaust nozzles with mixing devices for high-bypass-ratio engines. NASA TM-209948, Ohio, United States

Bastos LP (2016) Development and employment of a jet test rig facility for the analysis of installation effects on jets from serrated nozzles. PhD Dissertation, in Portuguese, Federal University of Santa Catarina

Tam CKW (2004) Computational aeroacoustics: an overview of computational challenges and applications. Int J Comput Fluid Dyn 18:547–567. https://doi.org/10.1080/10618560410001673551

Pinker RA (2004) The enhancement of the QinetiQ Noise Test Facility for larger-scale exhaust systems. AIAA Paper 2004-3019

Bridges J, Brown CA (2004) Parametric testing of chevrons on single flow hot jets. AIAA Paper 2004-2824

International Organization for Standardization (ISO) 3745 (2003) Acoustics—determination of sound power levels of noise sources using sound pressure—precision methods for anechoic and hemi-anechoic rooms

Zaman KBMQ (2011) Effect of nozzle exit conditions on subsonic jet noise. AIAA Paper 2011-2704

Viswanathan K (2003) Jet aeroacoustic testing: issues and implications. AIAA J 41:1674–1689

Bridges J, Wernet MP (2010) Establishing consensus turbulence statistics for hot subsonic jets. In: Proceedings of the 16th AIAA/CEAS aeroacoustics conference, Sweden, 2010

Bridges J, Brown C, Bozak R (2014) Experiments on exhaust noise of tightly integrated propulsion systems. AIAA Paper 2014-2904

Sirotto JRLN et al (2016) Validation of cold jet noise rig at Laboratory of Acoustic and Vibration (LVA), Federal University of Santa Catarina (UFSC). In: Proceedings of the 22th international congress on acoustics, Buenos Aires, 2016

Khavaran A, Bridges J (2009) Development of jet noise power spectral laws using SHJAR data. AIAA Paper 2009-3378

Tam CKW, Viswanathan K, Ahuja KK, Panda J (2008) The sources of jet noise: experimental evidence. J Fluid Mech 615:253–292. https://doi.org/10.1017/s0022112008003704

Callender B, Gutmark E, Dimicco R (2002) The design and validation of a coaxial nozzle acoustic test facility. AIAA Paper 2002-0369

Callender B, Gutmark EJ, Martens S (2010) Flow field characterization of coaxial conical and serrated (chevron) nozzles. Exp Fluids 48:637–649. https://doi.org/10.1007/s00348-009-0751-1

Nikam SR, Sharma SD (2014) Aero-acoustic characteristics of compressible jets from chevron nozzle. AIAA Paper 2014-2623. http://dx.doi.org/10.2514/6.2014-2623

Gutmark EJ, Callender B, Martens S (2006) Aeroacoustics of turbulent jets: flow structure, noise sources, and control. Int J Jpn Soc Mech Eng Ser B Fluids Therm Eng 49:1078–1085. https://doi.org/10.1299/jsmeb.49.1078

Acknowledgements

This study forms part of a joint technical–scientific program of the Federal University of Santa Catarina and EMBRAER. The authors would like to thank Mr. Igor A. Maia for the support to the flow measurements. The financial support from FINEP (Federal Agency of Research and Projects Financing), CNPq (Brazilian Research Council) and CAPES (Coordination for the Improvement of High-Level Personnel) is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: André Cavalieri.

Rights and permissions

About this article

Cite this article

Bastos, L.P., Deschamps, C.J., da Silva, A.R. et al. Development, validation and application of a newly developed rig facility for investigation of jet aeroacoustics. J Braz. Soc. Mech. Sci. Eng. 40, 171 (2018). https://doi.org/10.1007/s40430-018-1122-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1122-8