Abstract

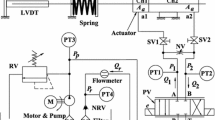

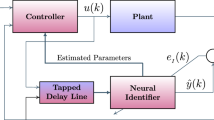

The friction and end-cushioning effects in the actuator have been taken care in consideration in the modeling of the actuation method related to an electrohydraulic system. A much simpler friction model that retains all the features of the existing models has been developed for this purpose. In addition, a systematic experimental characterization procedure has been proposed that has been utilized in a supplementary manner for the development of the elaborate nonlinear system model. An artificial neural-network model has been constructed by training with experimental data keeping in mind the variation of discharge through the proportional valve with pressure and command signal. All the nonlinear subsystem models thus obtained have been incorporated simultaneously in MATLAB/SIMULINK to monitor the actuation dynamics. The variations of the theoretical and investigated (via experiments) displacements of the piston against different command signals have been found to be quite close to each other.

Similar content being viewed by others

Abbreviations

- A a :

-

Cross-sectional area of actuator piston, (m2)

- A p :

-

Cross-sectional area of flow in pipe, (m2)

- Cd :

-

Coefficient of discharge

- C vi (i = 1–4):

-

Main-flow coefficient corresponding to the pressure drop ΔPi, (m3/(VPa1/2))

- d b :

-

Actuator bore diameter, (m)

- d c :

-

Cushion rod diameter, (m)

- d o :

-

Cushion bush diameter, (m)

- d r :

-

Actuator piston rod diameter, (m)

- E :

-

Error between measured output value t k and the network predicted value y k

- e f :

-

Feed forward voltage (V)

- F f :

-

Frictional force (N)

- f RV(Q s), f NRV(Q r):

-

Pressure-discharge characteristics for the relief valve and nonreturn valve, respectively, (Pa)

- K s :

-

Spring constant, (N/m)

- l b :

-

Inner length of actuator cylinder, (m)

- l c :

-

Length of cushion rod, (m)

- l l :

-

Lip length between cushion rod and actuator piston rod, (m)

- l p−s :

-

Pipe length between pump delivery and the supply port of PV, (m)

- l v1−a1 :

-

Pipe length between PV and chamber 1 of actuator, (m)

- l v2−a2 :

-

Pipe length between PV and chamber 2 of actuator, (m)

- l r−n :

-

Pipe length between NRV and the return port of PV, (m)

- m a :

-

Moving mass of the actuator, (kg)

- P A, P B :

-

Pressures at the two control ports A and B of the PV, respectively, (Pa)

- P c1, P c2 :

-

Cushioning volume pressures in chambers 1 and 2, respectively, (Pa)

- P n :

-

Pressures at the return port of PV and inlet to the NRV, respectively, (Pa)

- P p :

-

Pressures at the pump exit and inlet to the PV, respectively, (Pa)

- P Qdischarge :

-

Precision error of the discharge of the PV, (m3)

- P Pp :

-

Precision error of exit pressure of pump, (bar)

- P P1 :

-

Precision error of actuating pressure in chamber 1, (bar)

- P Pr :

-

Precision error of return line, (bar)

- P r :

-

Pressure of the return line to the tank, (Pa)

- P 1, P 2 :

-

Piston-actuating pressures in chambers 1 and 2, respectively, (Pa)

- Q a1, Q a2 :

-

Discharges through actuator control ports 1 and 2, respectively, (m3)

- Q v1, Q v2 :

-

Discharges through ports v1 and v2, respectively, of PV, (m3)

- S :

-

Stroke of the actuator, (m)

- S Qdischarge :

-

Bias limit of the discharge of the PV, (m3)

- S Pp :

-

Bias error of exit pressure of pump, (bar)

- S P1 :

-

Bias error of actuating pressure in chamber 1, (bar)

- S Pr :

-

Bias error of the return line to the tank, (bar)

- t factor :

-

Coverage factor

- \(V_{10} ,V_{20}\) :

-

Initial volumes in chambers 1 and 2, respectively, of the actuator, (m3)

- U Pdischarge :

-

Total experimental uncertainty, (m3)

- W :

-

Width of actuator piston, (m)

- w ij :

-

Weights

- y :

-

Displacement of actuator, (m)

- β :

-

Bulk modulus of the oil, (Pa)

- ρ :

-

Density of oil, (kg/m3)

- ς:

-

Damping coefficient of the PV

- NRV:

-

Nonreturn valve

- NV:

-

Needle valve

- LVDT:

-

Linear variable differential transformer

- PT:

-

Pressure transducer

- PV:

-

Proportional valve

- RV:

-

Relief valve

- SD:

-

Standard deviation

- SV:

-

Shut-off valve

References

Blackburn JF, Reethrop G, Shearer JL (1960) Fluid power control. The M.I.T Press, Cambridge

Merritt HE (1967) Hydraulic control systems. Wiley, New York

Precup RE, Rudas IJ, Tomescu ML, Tar JK (2008) Design and experiments for a class of fuzzy controlled servo systems. IEEE/ASME Trans Mechatron 13(1):22–35

Kaddissi C, Kenne JP, Saad M (2000) Identification and real-time control of an electrohydraulic servo system based on nonlinear backstepping. IEEE/ASME Trans Mechatron 12:12–22

Niksefat N, Sepehri N (2000) Design and experimental evaluation of a robust force controller for an electro-hydraulic actuator via quantitative feedback theory. Control Eng Pract 8(12):1335–1345

Lee SY, Blackburn JF (1952) Contributions to hydraulic control; 1-steady-state axial forces on control valve pistons. Trans ASME 74(6):1005–1011

Wu D, Burton R, Schoenau G (2002) An empirical discharge coefficient model for orifice flow. Int J Fluid Power 3(3):13–19

Mookherjee S, Acharyya S, Majumdar K, Sanyal D (2001) Static-performance based computer-aided design of a DDV and its sensitivity analysis. Int J Fluid Power 2:47–63

Zhang H, Nikiforuk PN, Ukrainetz PR (1993) Neural adaptive control of MIMO electrohydraulic servosystem. In: Proc. 3rd int conf fluid power transmission contr., Hangzhou, pp 315–320

de Wit CC, Olsson H, Astrom KJ, Lischinksy P (1995) A new model for control of systems with friction. IEEE Trans Autom Control 40(3):419–425

Owen WS, Croft EA (2003) The reduction of stick-slip friction in hydraulic actuators. IEEE/ASME Trans Mechatron 8(3):362–371

Janocha H, Pesotski D, Kuhnen K (2008) FPGA-based compensator of hysteretic actuator nonlinearities for highly dynamic applications. IEEE/ASME Trans Mechatron 13:112–116

Karnopp D (1985) Computer simulation of stick-slip friction in mechanical dynamic systems. Trans ASME J Dyn Syst Meas Control 107(1):100–103

Yanada H, Sekikawa Y (2008) Modeling of dynamic behaviors of friction. Mechatronics 18(7):330–339

Schwartz C, De Negri VJ, Climaco JV (2005) Modeling and analysis of an auto-adjustable stroke end cushioning device for hydraulic cylinders. J Braz Soc Mech Sci Eng VXXVII:415–425

Marton L, Fodor S, Sepehri N (2011) A practical method for friction identification in hydraulic actuators. Mechatronics 21(1):350–356

Rahmat MFA, Has Z, Husain AR, Md Sam Y, Ishaque K, Ghazaly R, Md Rozali S (2011) Modeling and controller design of an industrial hydraulic actuator system in the presence of friction and internal leakage. Int J Phys Sci 6(14):3502–3517

Guan C, Pan S (2008) Adaptive sliding mode control of electro-hydraulic system with nonlinear unknown parameters. Control Eng Pract 16(11):1275–1284

Rahmat MFA, Md Rozali S, Abdul Wahab N, Has Z, Jusoff K (2010) Modeling and controller design of an electro-hydraulic actuator system. Am J Appl Sci 7(8):1100–1108

Ghazali R, Sam YM, Rahmat MF, Jusoff K, Hashim AWIM (2011) Self-tuning control of an electro-hydraulic actuator system. Int J Smart Sens Intell Syst 4(2):189–204

Rahmat MFA, Abdul Wahab N, Has Z (2010) Application of draw wire sensor in position tracking of electro hydraulic actuator system. Int J Smart Sens Intell Syst 3(4):736–755

Shih KS, Li SHT, Tsai SH (2011) Novel adaptive fuzzy neural network controller for a class of certain non-linear systems. Proc I Mech Eng J Syst Control Eng 226:364–378

Knohl T, Unbehauen H (2000) Adaptive position control of electrohydraulic servo systems using ANN. Mechatronics 10(1):127–143

Alfayad S, Ouezdou FB, Namoun F, Gheng G (2011) High performance integrated electro-hydraulic actuator for robotics. Part II: theoretical modeling, simulation, control & comparison with real measurements. Sens Actuators A 169(1):124–132

Lippmann R (1987) An introduction to computing with neural nets. IEEE Acoust Speech Signal Process Mag 4(2):4–22

Rumelhart DE, Hinton G, Williams R (1986) Learning internal representations by backpropagating errors. In: Rumelhart DE, McClelland JL (eds) Parallel distributed processing: explorations in the microstructure of cognition, foundations, vol 1. MIT Press, Cambridge, pp 318–362

Cybenko G (1989) Approximation by superpositions of a sigmoidal function. Math Control Signals Syst 2(4):303–314

Sarkar BK, Das J, Saha R, Mookherjee S, Sanyal D (2013) Approaching servoclass tracking performance by a proportional valve-controlled system. IEEE/ASME Trans Mechatron 18(4):1425–1430

Mahato AC, Ghoshal SK, Samantaray AK (2017) Energy saving of a hydrostatic drive system by incorporating soft switch. J Braz Soc Mech Sci Eng 39(6):1929–1945

Taylor J (1997) Introduction to error analysis, the study of uncertainties in physical measurements. University Science Books, New York

Stern F, Muste M, Beninati ML, Eichinger WE (1999) Summary of experimental uncertainty assessment methodology with example (No. 406). IIHR Report

Bezarra MA, Santelli RE, Oliveira EP, Villar LS, Escaleira LA (2008) Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76(5):965–977

Acknowledgements

This work has been supported by AR&DB New Delhi and SAP-DRS of UGC New Delhi and Jadavpur University for equipment, and Prof. Dipankar Sanyal, Dr. Saikat Mookherjee, and Dr. Rana Saha of Mechanical Engineering Department, Jadavpur University, Kolkata for the help and valuable suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Jose A. dos Reis Parise.

Rights and permissions

About this article

Cite this article

Das, J., Mishra, S.K., Saha, R. et al. Nonlinear modeling of an electrohydraulic actuation system via experiments and its characterization by means of neural network. J Braz. Soc. Mech. Sci. Eng. 40, 58 (2018). https://doi.org/10.1007/s40430-018-0979-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-0979-x