Abstract

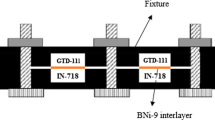

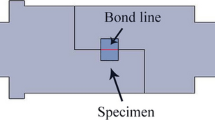

A new Ni–Cr–Si–B–Fe filler material is prepared for transient liquid-phase (TLP) bonding of Inconel 718 superalloy by mechanical alloying technique. The melting temperature range of the filler material and its activation energy of melting are determined by differential scanning calorimetry technique. The activation energy and melting temperature of the alloy powder decrease with increasing milling time. Inconel 718 alloy was joined via TLP by using the newly developed filler material. The effect of TLP bonding temperature and time on microstructural evolution and mechanical properties of the joint was investigated. Three distinct microstructural regions were observed in the bonding area: isothermal solidification zone consisting of a single-phase solid solution, diffusion affected zone consisting of extensive diffusion-induced precipitates of metallic boride, and unaffected base material. The ultimate shear strength and microhardness of the TLP-bonded joint increase with bonding time and temperature.

Similar content being viewed by others

References

J. Gordine, Weld. Res. Supp. 50, 480 (1971)

K.D. Ramkumara, S. Deva, K.V.P. Prabhakarb, R. Rajendranc, K.G. Mugundana, S. Narayanana, J. Mater. Process. Technol. 266, 52 (2019)

A. Lingenfelter, Welding of Inconel alloy 718: A Historical Overview, ed. by E.A. Loria (IMS, 1989) p. 673.

J. F. Radavich, The Pysical Metallurgy of Cast and Wrought Alloy 718, ed. by E.A. Lopia (IMS, 1989) p. 229.

N. Anbarasan, B.K. Gupta, S. Prakash, P. Muthukumar, R. Oyyaravelu, R.J.F. Kumar, S. Jerome, Mater. Today: Proc. 5, 7716 (2018)

R.G. Thompson, J. Miner. Metal. Mater. Soc. 40, 44 (1988)

W. Lin, J.C. Lippold, W.A. Baeslack, Weld. J. 72, 135 (1993)

R.G. Thompson, D.E. Mayo, B. Radhakrishnan, Metall. Trans. A 22, 557 (1991)

F. Jalilian, M. Jahazi, R.A.L. Drew, Mat. Sci. Eng. A 423, 269 (2006)

G.O. Cook, C.D. Sorensen, J. Mater. Sci. 46, 5305 (2011)

W.D.M. Donald, T.W. Egar, Mater. Sci. 22, 23 (1992)

W.F. Gale, D.A. Butts, Sci. Technol. Weld. Join. 9, 283 (2004)

J.K. Kim, H.J. Park, D.N. Shim, D.J. Kim, J. Manuf. Process. 25, 60 (2017)

R. Bakhtiari, A. Ekrami, Mater. Char. 66, 38 (2012)

M. Pouranvari, A. Ekrami, Mater. Des. 50, 694 (2013)

M.A. Arafin, M. Medraj, D.P. Turner, P. Bocher, Mat. Sci. Eng. A 447, 125 (2007)

W.D.M. Donald, T.W. Egar, Miner. Met. Mater. Soc. 93 (1992).

M.W. Tseng, D.B. Williams, K.K. Soni, R. Levi-Setti, J. Mater. Sci. 34, 5187 (1999)

A.D. Jamaloei, A. Khorram, A. Jafari, J. Manuf. Process. 29, 447 (2017)

I. Tuah-Poku, M. Dollar, T.B. Massalski, Metall. Trans. A 19, 675 (1988)

L. Lan, Z. Ren, J.Y.Z. Yang, Y. Zhong, Mater. Lett. 121, 223 (2014)

A.T. Egbewande, C. Chukwukaeme, O.A. Ojo, Mater. Charact. 59, 1051 (2008)

D.C. Murray, S.F. Corbin, J. Mat. Pro. Technol. 248, 92 (2017)

M. Pouranvari, A. Ekrami, A.H. Kokabi, Sci. Technol. Weld. Join. 19, 105 (2014)

S. Shakerin, H. Omidvar, S.E. Mirsalehi, Mater. Des. 89, 611 (2016)

F. Arhami, S.E. Mirsalehi, A. Sadeghian, J. Mat. Proc. Technol. 265, 219 (2019)

S.R. Cain, J.R. Wilcox, R. Venkatraman, Acta. Mater. 45, 701 (1997)

T.C. Illingworth, I.O. Golosnoy, T.W. Clyne, Mat. Sci. Eng. A 445, 493 (2007)

T. Ungár, Scr. Mater. 51, 777 (2004)

R. Gostariani, R. Ebrahimi, M.A. Asadabad, M.H. Paydar, Acta Metall. Sin. (Engl. Lett.) 31, 245 (2018)

M. SherifEl-Eskandarany, Mechanical alloying: Nanotechnology, Materials Science and Powder Metallurgy, 2nd edn. (Elsevier, London, 2015), p. 13

C.C. Koch, Scr. Mater. 34, 21 (1996)

M. Mattonaia, D. Pawcenisb, S.D. Seppiaa, J. Łojewskab, E. Ribechinia, Bio-resource Technol. 270, 270 (2018)

R.L. Blaine, H.E. Kissinger, Thermochim. Acta 540, 1 (2012)

N.F. Shkodich, S.G. Vadchenko, A.A. Nepapushev, D.Y. Kovalev, I.D. Kovalev, S. Ruvimov, A. Rogachev, A.S. Mukasyan, J. Alloy. Compd. 741, 575 (2018)

L. Lu, M.O. Lai, S. Zhang, J. Mat. Proc. Technol. 67, 100 (1997)

S. Ghaderi, F. Karimzadeh, A. Ashrafi, J. Manuf. Proc. 49, 162 (2020)

M. Pouranvar, A. Ekrami, A.H. Kokabi, J. Alloy. Compd. 563, 43 (2013)

N.R.J. Hynes, P.S. Velu, R. Kumar, M.K. Raja, Ceram. Int. 43, 7762 (2017)

X. Zhang, X. Shi, J. Wang, H. Li, K. Li, Y. Ren, Acta Metall. Sin. (Engl. Lett.) 27, 663 (2014)

M. Pouranvari, A. Ekrami, A.H. Kokabi, Mater. Sci. Eng. A 490, 229 (2008)

Acknowledgements

This work is financially supported by the Department of Mechanical engineering and Central Instruments Facility of Indian Institute of Technology Guwahati, India-781039.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Tarai, U.K., Robi, P.S. & Pal, S. Thermal Properties of Ni–Cr–Si–B–Fe Based Interlayer Material and Its Application in TLP Bonding of IN 718 Superalloy. Acta Metall. Sin. (Engl. Lett.) 33, 1666–1680 (2020). https://doi.org/10.1007/s40195-020-01089-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-020-01089-x