Abstract

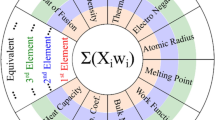

Bulk metallic glass has been a fascinating class of metallic systems with remarkable corrosion resistance, elastic modulus, and wear resistance, while evaluating the glass forming ability has been a very interesting aspect for decades. Machine learning techniques, viz., artificial neural networks and KNearest Regressor-based models have been developed in this work to predict the glass forming ability, given the composition of the bulk metallic glassy alloy. A new criterion of classification of atoms present in a bulk metallic glass is proposed. Feature importance analysis confirmed that the accuracy of the prediction depends mainly on change in enthalpy of mixing and change in entropy of mixing. However, among the artificial neural network models and KNearest Regressor models developed, the former showed a promising performance in prediction of the glass formation ability (critical thickness). It has been successfully demonstrated and validated with experimental critical thickness that the glass forming ability can be predicted using an artificial neural network given the elemental composition alone. A computational algorithm was also developed to classify the atoms as big/small in each given alloy. The outcome of this algorithm is used as input parameters to the ANN and other machine learning models used in this work.

Similar content being viewed by others

Data Availability

The processed data required to reproduce these findings are available to download from https://github.com/manju838/Atomic-Classification.git. An un-published preliminary version of this work (before modifications) was posted in https://www.researchsquare.com/article/rs-145304/v1 (available since January 15, 2021). Following link is for a computer program which takes BMG alloy composition as input, processes it and gives GFA (i.e., Dmax) for both the prediction models discussed in this work https://github.com/manju838/GFA-Prediction-of-BMGs.git

References

Inoue A (2001) Bulk amorphous alloys. In: Inoue A, Hashimoto K (eds) Amorphous and nanocrystalline materials. Advances in materials research, vol 3. Springer, Berlin

Suryanarayana C, Inoue A (2011) Bulk metallic glasses, 2nd edn. CRC Press, Florida

Inoue A, Takeuchi A (2011) Recent development and application products of bulk glassy alloys. Acta Mater 59(6):2243–2267. https://doi.org/10.1016/j.actamat.2010.11.027

Andrew H (2018) Understanding the origin of glass forming ability in metallic glasses. PhD Thesis, California Institute of Technology, Pasadena, California. https://resolver.caltech.edu/CaltechTHESIS:06082018-081351539

Chattopadhyay C, Satish Idury KSN, Bhatt J, Mondal K, Murty BS (2016) Critical evaluation of glass forming ability criteria. Mater Sci Technol 32(4):380. https://doi.org/10.1179/1743284715Y.0000000104

Lu ZP, Liu CT (2002) A new glass-forming ability criterion for bulk metallic glasses. Acta Mater 50:3501. https://doi.org/10.1016/S1359-6454(02)00166-0

Cai AH, Pan Y, Sun GX (2005) New thermodynamic parameter describing glass forming ability of bulk metallic glasses. Mater Sci Technol 21:1222–1226. https://doi.org/10.1179/174328405X58887

Cai AH, Pan Y, Gu J, Sun G-X (2006) A new criterion for glass forming ability of bulk metallic glasses. Mater Sci Technol 22(7):859–863. https://doi.org/10.1179/174328406X91005

Cai AH, Sun GX, Pan Y (2006) Evaluation of the parameters related to glass-forming ability of bulk metallic glasses. Mater Des 27(6):479–488. https://doi.org/10.1016/j.matdes.2004.11.015

Sun YT, Bai HY, Li MZ, Wang WH (2017) Machine-learning approach for prediction and understanding of glass-forming ability. J Phys Chem Lett 8:3434–3439. https://doi.org/10.1021/acs.jpclett.7b01046

Ward L, O’Keeffe S, Stevik J, Jelbert GR, Aykol M, Wolverton C (2018) A machine-learning approach for engineering bulk metallic glass alloys. Acta Mater 159:102–111. https://doi.org/10.1016/j.actamat.2018.08.002

Majid A, Ahsana SB, Tariq NH (2015) Modeling glass-forming ability of bulk metallic glasses using computational intelligent techniques. Appl Soft Comput 28:569–578. https://doi.org/10.1016/j.asoc.2014.11.037

Takeuchi A, Inoue A (2005) Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans 46(12):2817–2829. https://doi.org/10.2320/matertrans.46.2817

Xiong J, Shi SQ, Zhang TY (2020) A machine-learning approach to predicting and understanding the properties of amorphous metallic alloys. Mater Des 187:108378. https://doi.org/10.1016/j.matdes.2019.108378

Northcutt, CG (2019) hypopt 1.0.9. https://pypi.org/project/hypopt/

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Reddy, G.J., Kandavalli, M., Saboo, T. et al. Prediction of Glass Forming Ability of Bulk Metallic Glasses Using Machine Learning. Integr Mater Manuf Innov 10, 610–626 (2021). https://doi.org/10.1007/s40192-021-00239-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40192-021-00239-y