Abstract

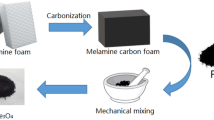

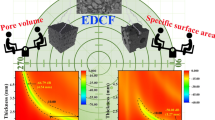

Porous three-dimensional SiC/melamine-derived carbon foam (3D-SiC/MDCF) composite with an original open pore structure was fabricated by the heat treatment of the commercial melamine foam (MF), carbonization of the stable MF, and chemical vapor deposition of the ultra-thin SiC coating. Scanning electron microscopy (SEM) and X-ray diffraction (XRD) were employed to detect the microstructure and morphology of the as-prepared composites. The results indicated that the 3D-SiC/MDCF composites with the coating structure were prepared successfully. The obtained minimum reflection loss was -29.50 dB when the frequency and absorption thickness were 11.36 GHz and 1.75 mm, respectively. Further, a novel strategy was put forward to state that the best microwave absorption property with a thin thickness of 1.65 mm was gained, where the minimum reflection loss was -24.51 dB and the frequency bandwidth was 3.08 GHz. The excellent electromagnetic wave absorption ability resulted from the specific cladding structure, which could change the raw dielectric property to acquire excellent impedance matching. This present work had a certain extend reference meaning for the potential applications of the lightweight wave absorption materials with target functionalities.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Chen Z, Chen ZF, Yang ZG, et al. Preparation and characterization of vacuum insulation panels with super-stratified glass fiber core material. Energy 2015, 93: 945–954.

Tang J, Meng HM, Huang LL. Energy-saving and environmentally friendly electrodeposition of ?-MnO2. RSC Adv 2014, 4: 16512–16516.

Chu S, Majumdar A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488: 294–303.

Chen ZP, Xu C, Ma CQ, et al. Lightweight and flexible graphene foam composites for high-performance electromagnetic interference shielding. Adv Mater 2013, 25: 1296–1300.

Duan WY, Yin XW, Li Q, et al. A review of absorption properties in silicon-based polymer derived ceramics. J Eur Ceram Soc 2016, 36: 3681–3689.

Li Q, Yin XW, Duan WY, et al. Electrical, dielectric and microwave-absorption properties of polymer derived SiC ceramics in X band. J Alloys Compd 2013, 565: 66–72.

Duan WY, Yin XW, Luo CJ, et al. Microwave-absorption properties of SiOC ceramics derived from novel hyperbranched ferrocene-containing polysiloxane. J Eur Ceram Soc 2017, 37: 2021–2030.

Wang P, Cheng LF, Zhang LT. One-dimensional carbon/SiC nanocomposites with tunable dielectric and broadband electromagnetic wave absorption properties. Carbon 2017, 125: 207–220.

Wen B, Cao MS, Hou ZL, et al. Temperature dependent microwave attenuation behavior for carbon-nanotube/silica composites. Carbon 2013, 65: 124–139.

Zhong B, Sai TQ, Xia L, et al. High-efficient production of SiC/SiO2 core-shell nanowires for effective microwave absorption. Mater Des 2017, 121: 185–193.

Liang XH, Quan B, Ji GB, et al. Novel nanoporous carbon derived from metal-organic frameworks with tunable electromagnetic wave absorption capabilities. Inorg Chem Front 2016, 3: 1516–1526.

He S, Wang GS, Lu C, et al. Controllable fabrication of CuS hierarchical nanostructures and their optical, photocatalytic, and wave absorption properties. ChemPlusChem 2013, 78: 250–258.

Yuan XY, Cheng LF, Guo SW, et al. High-temperature microwave absorbing properties of ordered mesoporous inter-filled SiC/SiO2 composites. Ceram Int 2017, 43: 282–288.

Wang P, Cheng LF, Zhang YN, et al. Flexible, hydrophobic SiC ceramic nanofibers used as high frequency electromagnetic wave absorbers. Ceram Int 2017, 43: 7424–7435.

Li GM, Wang LC, Li WX, et al. CoFe2O4 and/or Co3Fe7 loaded porous activated carbon balls as a lightweight microwave absorbent. Phys Chem Chem Phys 2014, 16: 12385–12392.

Zhao B, Shao G, Fan BB, et al. Fabrication and enhanced microwave absorption properties of Al2O3 nanoflake-coated Ni core-shell composite microspheres. RSC Adv 2014, 4: 57424–57429.

Cheng Y, Guo YH, Zhang ZY, et al. Facile synthesis of NixCo3-xS4 hollow nanoprism with broader electromagnetic absorption properties: Effect of Ni/Co atomic ratios. J Alloys Compd 2018, 767: 323–329.

Moglie F, Micheli D, Laurenzi S, et al. Electromagnetic shielding performance of carbon foams. Carbon 2012, 50: 1972–1980.

Zhang Y, Huang Y, Zhang TF, et al. Broadband and tunable high-performance microwave absorption of an ultralight and highly compressible graphene foam. Adv Mater 2015, 27: 2049–2053.

Kumar R, Dhakate SR, Gupta T, et al. Effective improvement of the properties of light weight carbon foam by decoration with multi-wall carbon nanotubes. J Mater Chem A 2013, 1: 5727–5735.

Fang ZG, Cao XM, Li CS, et al. Investigation of carbon foams as microwave absorber: Numerical prediction and experimental validation. Carbon 2006, 44: 3368–3370.

Crespo M, González M, Elías AL, et al. Ultra-light carbon nanotube sponge as an efficient electromagnetic shielding material in the GHz range. Phys Status Solidi RRL 2014, 8: 698–704.

Li Y, Shen B, Pei XL, et al. Ultrathin carbon foams for effective electromagnetic interference shielding. Carbon 2016, 100: 375–385.

Yang J, Shen ZM, Hao ZB. Microwave characteristics of sandwich composites with mesophase pitch carbon foams as core. Carbon 2004, 42: 1882–1885.

Zhu XW, Jiang DL, Tan SH. Microwave absorbing property of SiC reticulated porous ceramics. J Inorg Mater 2002, 17: 1152–1156. (in Chinese)

Zhang HT, Zhang JS, Zhang HY. Computation of radar absorbing silicon carbide foams and their silica matrix composites. Comput Mater Sci 2007, 38: 857–864.

Huang HD, Liu CY, Zhou D, et al. Cellulose composite aerogel for highly efficient electromagnetic interference shielding. J Mater Chem A 2015, 3: 4983–4991.

Xie AM, Wu F, Sun MX, et al. Self-assembled ultralight three-dimensional polypyrrole aerogel for effective electromagnetic absorption. Appl Phys Lett 2015, 106: 222902.

Chen K, Li XH, Lv DS, et al. Study on microwave absorption properties of metal-containing foam glass. Mater Sci Eng B 2011, 176: 1239–1242.

He YF, Gong RZ. Preparation and microwave absorption properties of foam-based honeycomb sandwich structures. Europhys Lett 2009, 85: 58003.

Wang S, Xiao N, Zhou Y, et al. Lightweight carbon foam from coal liquefaction residue with broad-band microwave absorbing capability. Carbon 2016, 105: 224–226.

Song CQ, Yin XW, Han MK, et al. Three-dimensional reduced graphene oxide foam modified with ZnO nanowires for enhanced microwave absorption properties. Carbon 2017, 116: 50–58.

Chiu SC, Yu HC, Li YY. High electromagnetic wave absorption performance of silicon carbide nanowires in the gigahertz range. J Phys Chem C 2010, 114: 1947–1952.

Liu HT, Cheng HF, Wang J, et al. Dielectric properties of the SiC fiber-reinforced SiC matrix composites with the CVD SiC interphases. J Alloys Compd 2010, 491: 248–251.

Duan WY, Yin XW, Cao FX, et al. Absorption properties of twinned SiC nanowires reinforced Si3N4 composites fabricated by 3D-prining. Mater Lett 2015, 159: 257–260.

Wu RB, Pan Y, Yang GY, et al. Twinned SiC zigzag nanoneedles. J Phys Chem C 2007, 111: 6233–6237.

Duan WY, Yin XW, Li Q, et al. Synthesis and microwave absorption properties of SiC nanowires reinforced SiOC ceramic. J Eur Ceram Soc 2014, 34: 257–266.

Wen LX, Ma YJ, Dai B, et al. Preparation and dielectric properties of SiC nanowires self-sacrificially templated by carbonated bacterial cellulose. Mater Res Bull 2013, 48: 687–690.

Li ZM, Zhou WC, Su XL, et al. Effect of boron doping on microwave dielectric properties of SiC powder synthesized by combustion synthesis. J Alloys Compd 2011, 509: 973–976.

Mu Y, Zhou WC, Hu Y, et al. Enhanced microwave absorbing properties of 2.5D SiCf/SiC composites fabricated by a modified precursor infiltration and pyrolysis process. J Alloys Compd 2015, 637: 261–266.

Su XL, Zhou WC, Xu J, et al. Preparation and dielectric property of B and N-codoped SiC powder by combustion synthesis. J Alloys Compd 2013, 551: 343–347.

Xiao SS, Mei H, Han DY, et al. Ultralight lamellar amorphous carbon foam nanostructured by SiC nanowires for tunable electromagnetic wave absorption. Carbon 2017, 122: 718–725.

Li Q, Yin XW, Duan WY, et al. Improved dielectric and electromagnetic interference shielding properties of ferrocene-modified polycarbosilane derived SiC/C composite ceramics. J Eur Ceram Soc 2014, 34: 2187–2201.

Dong S, Zhang WZ, Zhang XH, et al. Designable synthesis of core-shell SiCw@C heterostructures with thickness-dependent electromagnetic wave absorption between the whole X-band and Ku-band. Chem Eng J 2018, 354: 767–776.

Ye XL, Chen ZF, Ai SF, et al. Effect of thickness of SiC films on compression and thermal properties of SiC/CF composites. Ceramic Int 2019, 45: 4674–4679.

Ye XL, Chen ZF, Ai SF, et al. Synthesis and microwave absorption properties of novel reticulation SiC/Porous melamine-derived carbon foam. J Alloys Compd 2019, 791: 883–891.

Inagaki M, Qiu JS, Guo QG. Carbon foam: Preparation and application. Carbon 2015, 87: 128–152.

Fang ZG, Li CS, Sun JY, et al. The electromagnetic characteristics of carbon foams. Carbon 2007, 45: 2873–2879.

Ge YC, Liu YQ, Wu S, et al. Characterization of SiC nanowires prepared on C/C composite without catalyst by CVD. Trans Nonferrous Met Soc China 2015, 25: 3258–3264.

Zhao B, Shao G, Fan BB, et al. Facile synthesis and enhanced microwave absorption properties of novel hierarchical heterostructures based on a Ni microsphere-CuO nano-rice core-shell composite. Phys Chem Chem Phys 2015, 17: 6044–6052.

Wang P, Cheng LF, Zhang YN, et al. Electrospinning of graphite/SiC hybrid nanowires with tunable dielectric and microwave absorption characteristics. Compos Part Appl Sci Manuf 2018, 104: 68–80.

Dong S, Hu P, Zhang XH, et al. Carbon foams modified with in situ formation of Si3N4 and SiC for enhanced electromagnetic microwave absorption property and thermostability. Ceram Int 2018, 44: 7141–7150.

Liu W, Tan SJ, Yang ZH, et al. Hollow graphite spheres embedded in porous amorphous carbon matrices as lightweight and low-frequency microwave absorbing material through modulating dielectric loss. Carbon 2018, 138: 143–153.

Gu WH, Quan B, Liang XH, et al. Composition and structure design of Co3O4 nanowires network by nickel foam with effective electromagnetic performance in C and X band. ACS Sustain Chem Eng 2019, 7: 5543–5552.

Liang XH, Quan B, Ji GB, et al. Novel nanoporous carbon derived from metal-organic frameworks with tunable electromagnetic wave absorption capabilities. Inorg Chem Front 2016, 3: 1516–1526.

Liang XH, Zhang XM, Liu W, et al. A simple hydrothermal process to grow MoS2 nanosheets with excellent dielectric loss and microwave absorption performance. J Mater Chem C 2016, 4: 6816–6821.

Lv H, Liang XH, Ji GB, et al. Porous three-dimensional flower-like Co/CoO and its excellent electromagnetic absorption properties. ACS Appl Mater Interfaces 2015, 7: 9776–9783.

Liang XH, Quan B, Sun YS, et al. Multiple interfaces structure derived from metal-organic frameworks for excellent electromagnetic wave absorption. Part Part Syst Charact 2017, 34: 1700006.

Fang JY, Liu T, Chen Z, et al. A wormhole-like porous carbon/magnetic particles composite as an efficient broadband electromagnetic wave absorber. Nanoscale 2016, 8: 8899–8909.

Acknowledgements

The present work was supported by the National Natural Science Foundation of China (Grant Nos. 51772151 and 51761145103) and the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ye, X., Chen, Z., Ai, S. et al. Porous SiC/melamine-derived carbon foam frameworks with excellent electromagnetic wave absorbing capacity. J Adv Ceram 8, 479–488 (2019). https://doi.org/10.1007/s40145-019-0328-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40145-019-0328-2