Abstract

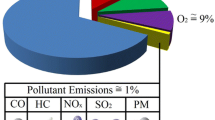

Diesel vehicles are the nerves and veins of transportation, particularly in developing countries. With the rapid rate of modernization, increasing demand of fuel is inevitable. The exponential increase in fuel prices and the scarcity of its supply from the environment have promoted interest in the development of alternative sources of fuel. In this work, genus Ricinus communis L. was studied in order to delimit their potential as a raw material for biodiesel production. Further, castor oil, ethyl ester were prepared by transesterification using potassium hydroxide (KOH) as a catalyst and tested on a four-stroke, single-cylinder compression ignition engine. The test was carried out at a constant speed of 3000 rpm at different loads. The results represent a substantial decrease in carbon monoxide (CO) emission with an increasing biodiesel percentage. The reduction of CO in B05, B10, B15 and B20 averaged 11.75, 22.02, 24.23 and 28.79 %, respectively, compared to mineral diesel. The emission results of the comparative test indicated that CO, oxygen (O2) and smoke density emissions are found to be lower when the engine is filled with B05, B10, B15 and B20 as compared to mineral diesel, while carbon dioxide (CO2) and nitrogen oxide (NOx) with B05, B10, B15 and B20 are found to increase marginally. Brake thermal efficiency and brake specific fuel consumption decrease and increase respectively in biodiesel with different blends in comparison of mineral diesel.

Similar content being viewed by others

References

D.P. Deshpande, Y.D. Urunkar, P.D. Thakare, Production of biodiesel from castor oil using acid and base catalysts. Res. J. Chem. Sci. 2(8), 51–56 (2012)

Carmen Leonor Barajas Forero, Biodiesel from castor oil: a promising fuel for cold weather, clabarajas@bari.ufps.edu.co (2006)

A. Card, D. Whiting, C. Wilson, Colorado State University Extension) and Jean Reeder, Organic Fertilizers (Colorado State University Extension, Fort Collins, 2011)

M. Vanaja, M. Jyothi, P. Ratnakumar, P. Vagheera, P. Raghuram Reddy, N. Jyothi Lakshmi, S.K. Yadav, M. Maheshwari, B. Venkateswarlu, Growth and yield responses of castor bean(Ricinus communis L.) to two enhanced CO2 levels. Plant Soil Environ. 1(54), 38–46 (2008)

K. Pramanik, Properties and use of jatropha curcas oil and diesel in compression ignition engine. Renew. Energy (Elsevier) 28(2), 239–248 (2003)

D.G. Hayes, V.K. Mannam, R. Ye, H. Zhao, S. Ortega, M. Claudia Montiel, Modification of oligo-ricinoleic acid and its derivatives with 10-undecenoic acid via lipase-catalyzed esterification. Polymers 4, 1037–1055 (2012). doi:10.3390/polym4021037

J. Salimon, D.A.M. Noor, A.T. Nazrizawati, M.Y. Mohd Firdaus, A. Noraishah, Fatty acid composition and physicochemical properties of Malaysian Castor Bean Ricinus communis L. seed oil. Sains Malaysiana 39(5), 761–764 (2010)

S.L. Seager, M.R. Slabaugh, Organic and Biochemistry for Today, 4th edn. (2004)

P. Neelamegam, S. Krishnaraj, Estimation of liquid viscosities of oils using associative neural networks. Ind. J. Chem. Technol. 18, 463–468 (2011)

Jeethendra Kumar P K, Ajeya PadmaJeeth and Santhosh K, Measurement of viscosity of liquids by the Stoke’s method, lab experiments Kamal Jeeth instrumentation and service unit Vol-12, No-2, June-2012

P. Eshratabadi, M.H. Sarrafzadeh, H. Fatemi, M. Ghavami, N. Gholipour-Zanjani, Enhanced degumming of soyabean oil and its influences on degummed oil and lecithin. Iran. J. Chem. Eng. 5(1), 65–73 (2008)

U.F. Ishaq, Production, refining and evaluation pf castor oil, Reg. no: 9Sn013EH, (2004)

Oil methyl ester and its diesel blends, Int. J. Appl. Sci. Eng. Technol. (IJASET) 4(2), (2007)

P. Sreenivas, V.R. Mamilla, K. Chandra Sekhar, Development of biodiesel from castor oil. Int. J. Energy Sci. 1(3), 192–197 (2011)

F. Wang, D.M. Zhang, Y.F. Ding, L.X. Zhang, M. Yang, B.L. Jiang, S.M. Zhang, M.Y. Ai, G.W. Liu, S.J. Zhi, F. Lian, X. Ouyang, L. Li, The effect of nanohybrid materials on the pour-point and viscosity depressing of waxy crude oil. Chin. Sci. Bull. 56(1), 14–17 (2011). doi:10.1007/s11434-010-4174-4

P.S. Bimbhra, Electrical Machinery [Theory, Performance and Applications], 7th edn. (Khanna Publishers, Delhi, 2009)

A.E. Fitzgerald, C. Kingsley Jr, S.D. Umans, Electric Machinery, 6th edn. (McGraw-Hill, New York, 2003)

I. Lozada, J. Islas, G. Grande, Environmental and economic feasibility of palm oil biodiesel in the Mexican transportation sector. Renew. Sustain. Energy Rev. (Elsevier). doi:10.1016/j.rser.2009.06.034

file:///F:/MS/3%20rd%20SEM/ENERGY%20CON/U1/Thermoelectric%20effect%20-%20Wikipedia,%20the%20free%20encyclopedia.htm

M. Pandian, S.P. Sivapirakasam, M. Udayakumar, Influence of injection timing on performance and emission characteristics of naturally aspirated twin cylinder CIDI Engine using bio-diesel blend as fuel, Int. J. Recent Trends Eng. 1(5) (2009)

F. Nielsen, B. hill, J. de Jongh, Castor (Ricinus communis) potential of castor for bio-fuel production prepared by FACT Foundation, 2nd ed. (2011)

A.K. Agarwal, K. Rajamanoharan, Experimental investigations of performance and emissions of Karanja oil and its blends in a single cylinder agricultural diesel engine. Appl. Energy 86, 106–112 (2009)

K. Sureshkumar, R. Velraj, Ganesan R., Performance and exhaust emission characteristics of a CI engine fueled with Pongamia pinnata methyl ester (PPME) and its blends with diesel. Renew. Energy 33, 2294–2302 (2008)

M.M. Conceicao, R.A. Candeia, F.C. Silva, A.F. Bezerra, V.J. Fernandes Jr, A.G. Souza, Thermoanalytical characterization of castor oil biodiesel. Renew. Sustain. 11(5), 964–975 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kanwar, R., Sharma, P.K., Singh, A.N. et al. Performance and Emission Characteristics of a Compression Ignition Engine Operating on Blends of Castor Oil Biodiesel–Diesel. J. Inst. Eng. India Ser. C 98, 147–154 (2017). https://doi.org/10.1007/s40032-016-0243-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-016-0243-z