Abstract

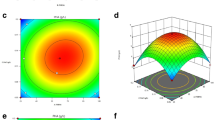

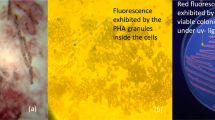

Bioplastics are biobased materials produced from renewable sources like vegetable fats and oils, corn starch, straw, woodchips, sawdust, and recycled food wastes. Microbial polyhydroxyalkanoate (PHA), a type of bioplastics, has unique biocompatibility, non-toxicity, and biodegradability properties, making it suitable as an eco-friendly plastic material. Bacillus megaterium DSM 509 is known to produce short-chain length (scl) PHA. The present study explores the capability of Bacillus megaterium DSM 509 to produce a novel type of PHA, medium-chain length (mcl), and its mixture with scl-PHA. Statistical modelling and experimental results were used to optimize the growth conditions for enhanced production of cost-effective and biocompatible polyhydroxyoctanoates and polyhydroxydecanoates. A 6-run mixture design for glycerol and ammonium sulphate concentrations ratio was performed. A linear regression model was built based on experimental data, and the optimum conditions for different glycerol and nitrogen concentrations were derived and validated. A positive correlation (r2, 0.95, and 0.87) was observed, resulting in the model’s fitness. Optical density studies showed the impact of dissolved oxygen (DO) content on PHA production. It was observed that PHA production was enhanced for each sample at the optimum value of DO. The highest intracellular PHA was produced by microbial culture, having a C/N ratio of 25 (high glycerol and low nitrogen source) as detected on FTIR: peak height at 1740 cm−1 was 2.157. Results on gas chromatographic (GC–MS and GC-FID) analysis confirmed the presence of a mixture of scl and mcl-PHA as well as their monomer composition. The maximum PHA production obtained was 4.73 g.L−1 (60%) of dry cell weight at C/N ratio 25. The nature and physical form of bacterial cells was revealed using transmission electron microscopy (TEM). It is concluded that Bacillus megaterium is capable of producing a combination of scl-PHA and mcl-PHA, while feeding on nitrogen-deficient mineral medium.

Similar content being viewed by others

References

Chee JY et al (2010) Bacterially produced polyhydroxyalkanoate (PHA): converting renewable resources into bioplastics. App Microbiol Biotechnol 2:1395–1404

Koller M, Braunegg G (2015) Potential and Prospects of Continuous Polyhydroxyalkanoate (PHA) Production. Bioengineering 2(2):94–121

Napathorn S et al (2010) Biosynthesis and biocompatibility of biodegradable poly(3-hydroxybutyrate-co-4-hydroxybutyrate). Poly Degrad and Stab 95(10):2003–2012

Jendrossek D (2009) Polyhydroxyalkanoate granules are complex subcellular organelles (Carbonosomes). J Bacteriol 191(10):3195–3202

Jendrossek D, Handrick aR (2002) Microbial degradation of polyhydroxyalkanoates. Annu Rev Microbiol. 56:403–32

Steinbüchel A, Hein aS (2001) Biochemical and molecular basis of microbial synthesis of polyhydroxyalkanoates in microorganisms. Adv Biochem Eng Biotechnol 71:81–123

Zinn M, Witholt B, Egli aT (2001) Occurrence, synthesis and medical application of bacterial polyhydroxyalkanoate. Adv Drug Deliv Rev 53:5–12

Salma S et al (2021) Polyhydroxyalkanoates: Next generation natural biomolecules and a solution for the world’s future economy. Inter J of Bio Macro 166:297–321

Amache R et al (2013) Advances in PHAs production. Chem Eng Trans 32:931–936

Kunasundari, Sudesh a (2011) Isolation and recovery of microbial polyhydroxyalkanoates. Exp Poly Lett 5(7):620–634

Wang S et al (2016) Modification and potential application of short-chain-length polyhydroxyalkanoate (SCL-PHA). Polym 8:273

Vibhuti S, Rutika S, Reena aG (2021) Polyhydroxyalkanoate (PHA): properties and Modifications. Poly 212

Ahmad MG, Muhammad HA, Mohamad aSMA (2015) Modification of polyhydroxyalkanoates (PHAs). RSC Green chem. 30:141–182

Ojumu TV, Yu J, Solomon aBO (2004) Production of polyhydroxyalkanoates, a bacterial biodegradable polymer. Afri J Biotechnol. 3(1):18–24

Aramvash A (2016) Effective enhancement of hydroxyvalerate content of PHBV in Cupriavidus necator and its characterization. Int j of biol macro 87:397–404

Sindhu R et al (2013) Pentose-rich hydrolysate from acid pretreated rice straw as a carbon source for the production of poly-3-hydroxybutyrate. Biochem Eng J 78:67–72

Li M, Eskridge KM, Wilkins MR (2019) Optimization of polyhydroxybutyrate production by experimental design of combined ternary mixture (glucose, xylose and arabinose) and process variables (sugar concentration, molar C: N ratio). Bioprocess Biosyst Eng 42(9):1495–1506

Kannengiesser J et al (2016) Extraction of medium chain fatty acids from organic municipal waste and subsequent production of bio-based fuels. Waste Management 78–83

Basak B et al (2011) Effect of nitrogen limitation on enrichment of activated sludge for PHA production. Bioprocess Biosyst Eng 34(8):1007–1016

Ganesh Saratale R et al (2021) A comprehensive overview and recent advances on polyhydroxyalkanoates (PHA) production using various organic waste streams. Bioresour Technol 325:124685

Ying L et al (2021) Optimization of medium-chain-length polyhydroxyalkanoate production by Pseudomonas putida KT2440 from co-metabolism of glycerol and octanoate. Can J Chem Eng 99(3):657–666

Shailja G, HNB and CEW (2021) An update on the future prospects of glycerol polymers. Polymer International 70(7): 911–917

García G et al (2021) Accumulation of PHA in the Microalgae Scenedesmus sp. under Nutrient-Deficient Conditions. Polymers 13(1):131

Lorini L et al (2020) High rate selection of PHA accumulating mixed cultures in sequencing batch reactors with uncoupled carbon and nitrogen feeding. New Biotechnol 56:140–148

Serafim LS et al (2004) Optimization of polyhydroxybutyrate production by mixed cultures submitted to aerobic dynamic feeding conditions. Biotechnol Bioeng 87(2):145–160

Albuquerque MGE et al (2007) Strategies for the development of a side stream process for polyhydroxyalkanoate (PHA) production from sugar cane molasses. J Biotechnol 130(4):411–421

Bengtsson S et al (2008) Production of polyhydroxyalkanoates by activated sludge treating a paper mill wastewater. Biores Technol 99(3):509–516

Pohlmann A et al (2006) Genome sequence of the bioplastic-producing ‘Knallgas’ bacterium Ralstonia eutropha H16. Nat Biotechnol 24:1257–1262

Shahid S et al (2013) Impact of carbon source and variable nitrogen conditions on bacterial biosynthesis of polyhydroxyalkanoates: evidence of an atypical metabolism in Bacillus megaterium DSM 509. J Biosci Bioeng 116(3):302–308

Shahid S et al (2021) New model development for qualitative and quantitative analysis of microbial polyhydroxyalkanoates: a comparison of Fourier Transform Infrared Spectroscopy with Gas Chromatography. J Biotechnol 329:38–48

Koller M, Niebelschutz Ha, Braunegg G (2013) Strategies for recovery and purification of poly[(R)-3-hydroxyalkanoates] (PHA) biopolyesters from surrounding biomass. Eng Life Sci 13:549–562

Verlinden RA et al (2007) Bacterial synthesis of biodegradable polyhydroxyalkanoates. J Appl Microbiol 102:1437–1449

Salma S et al (2013) Impact of carbon source and variable nitrogen conditions on bacterial biosynthesis of polyhydroxyalkanoates: evidence of an atypical metabolism in Bacillus megaterium DSM 509. J Biosci & Bioeng 116(3):302–308

Aguirre Ezkauriatza EJ et al (2010) Production of probiotic biomass (Lactobacillus casei) in goat milk whey: comparison of batch, continuous and fed-batch cultures. Bioresour Technol 101(8):2837–2844

Amiel C (2000) Potentiality of Fourier transform infrared spectroscopy (FTIR) for discrimination and identification of dairy lactic acid bacteria. Lait 80(4):445–459

Huijberts GNM, Eggink G (1996) Production of poly(3-hydroxyalkanoates) by Pseudomonas putida KT2442 in continuous cultures. Appl Microbiol Biotechnol 46(3):233–239

Lageveen RG et al (1988) Formation of polyesters by Pseudomonas oleovorans: effect of substrates on formation and composition of poly-(R)-3-hydroxyalkanoates and poly-(R)-3-hydroxyalkenoates. Appl Environ Microbiol 54(12):2924–2932

Yang M, Zhu SA, Chen Y (2004) Studies on bone marrow stromal cells affinity of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate). Biomaterials 25:1365–73

Choonut A et al (2020) Study on mcl PHA Production by novel thermotolerant gram positive isolate. J Polym Environ 28:2410–2421

Fontaine P, Mosrati R, Corroler D (2017) Medium chain length polyhydroxyalkanoates biosynthesis in Pseudomonas putida mt 2 is enhanced by co-metabolism of glycerol/octanoate or fatty acids mixtures. Int J Biol Macromol 98:430–435

Faccin DJL et al (2009) Optimization of C N ratio and minimal initial carbon source for poly(3 hydroxybutyrate) production by Bacillus megaterium. J Chem Technol Biotechnol 84(12):1756–1761

Moralejo-Gárate H et al (2013) Impact of oxygen limitation on glycerol-based biopolymer production by bacterial enrichments. Water Res 47(3):1209–1217

Tu W, Zhang D, Wang H (2019) Polyhydroxyalkanoates (PHA) production from fermented thermal-hydrolyzed sludge by mixed microbial cultures: The link between phosphorus and PHA yields. Waste Manage 96:149–157

Faccin DJL et al (2009) Optimization of C: N ratio and minimal initial carbon source for poly(3-hydroxybutyrate) production by Bacillus megaterium. J Chem Technol Biotechnol 84(12):1756–1761

Dunlop WF, Robards AW (1973) Ultrastructural study of poly-β-hydroxybutyrate granules from Bacillus cereus. J Bacteriol 114:1271–1280

Çetin D et al (2006) Poly-β-hydroxybutyrate accumulation and releasing by hydrogen producing bacteria, Rhodobacter sphaeroides O.U.001. a transmission electron microscopic study. African J Biotechnol 5:2069–2072

Lauzier C et al (1992) Structural study of isolated poly (β-hydroxybutyrate) granules. Polymer 33:823–827

Quillaguaman J et al (2005) Poly (β-hydroxybutyrate) production by a moderate halophile, Halomonas boliviensis LC1 using starch hydrolysate as substrate. J Appl Microbiol 99:151–157

Acknowledgements

Facilities of SEM and FTIR are provided by Unité de Recherche ABTE (Aliments Bioprocédés Toxicologie Environnements), EA 4651, Esplanade de la Paix.

Funding

Higher Education Commission (HEC), Islamabad, Pakistan, supported this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shahid, S., Corroler, D., Mosrati, R. et al. Optimization of growth conditions for the biosynthesis of medium-chain length polyhydroxyalkanoates from Bacillus megaterium DSM 509: experimental analysis, statistical modelling, and characterization. Biomass Conv. Bioref. 13, 12249–12264 (2023). https://doi.org/10.1007/s13399-021-01986-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01986-w