Abstract

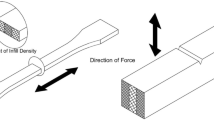

The present research has focused on investigation into the low-velocity impact (LVI) behavior of 3D-printed poly-lactic acid thermoplastic material processed by fused deposition modeling. Four different infill density (ID) percentages, namely 40%, 60%, 80%, and 100%, were manufactured and subjected to the LVI test with 50 J energy input. The specimens were impacted using 12.7-mm hemispherical portion with conical head (ϕ 20 mm) striker which introduced two penetration stages. The impact characteristics in terms of velocity–time, force–time, and energy–time curves were investigated and reported. The penetration velocity limit, penetration energy, peak energy, and peak force were measured and discussed. The results revealed that the impact characteristics started to increase as the function of ID. The surface topography and fractured surfaces were examined using SEM. The fracture surfaces of 80% and 100% ID samples exhibited more viscous plastic deformation, indicating more energy absorption and load-carrying capacity.

Similar content being viewed by others

References

Domingo-Espin M, Puigoriol-Forcada J M, Garcia-Granada A-A, Llumà J, Borros S, and Reyes G, Mater Des83 (2015) 670.

Wulle F, Coupek D, Schäffner F, Verl A, Oberhofer F, and Maier T, Proc CIRP60 (2017) 229.

Galantucci L M, Lavecchia F, and Percoco G, CIRP Ann59 (2010) 247.

Mueller B, Assem Autom32 (2012) 151.

Kardel K, Ghaednia H, Carrano A L, and Marghitu D B, Addit Manuf14 (2017) 87.

Serra T, Planell J A, and Navarro M, Acta Biomater9 (2013) 5521.

Tymrak B M, Kreiger M, and Pearce J M, Mater Des58 (2014) 242.

Lederle F, Meyer F, Brunotte G-P, Kaldun C, and Hübner E G, Prog Addit Manuf1 (2016) 3.

Aloyaydi B A, Sivasankaran S, and Ammar H R, AIMS Mater Sci6 (2019) 1033.

Lee B H, Abdullah J, and Khan Z A, J Mater Process Technol169 (2005) 54.

Riddick J C, Haile M A, Von Wahlde R, Cole D P, Bamiduro O, and Johnson T E, Addit Manuf11 (2016) 49

Yao T, Deng Z, Zhang K, and Li S, Compos Part B Eng163 (2019) 393.

Griffiths C A, Howarth J, Rowbotham G-A, and Rees A, Proc CIRP49 (2016) 28.

Roberson D A, Perez A R T, Shemelya C M, Rivera A, MacDonald E, and Wicker R B, Addit Manuf7 (2015) 1.

Zou R, Xia Y, Liu S, Hu P, Hou W, Hu Q, and Shan C, Compos Part B Eng99 (2016) 506.

Owolabi G, Peterson A, Habtour E, Riddick J, Coatney M, Olasumboye A, and Bolling D, Int J Mech Mater Eng11 (2016) 3.

Huang B and Singamneni S, J Compos Mater49 (2015) 363.

ASM International, Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event, ASTM International, West Conshohocken (2007).

Zhou F, Zhang M, Cao X, Zhang Z, Chen X, Xiao Y, Liang Y, Wong T-W, Li T, and Xu Z, Sens Actuators A Phys292 (2019) 112.

Soliman E M, Sheyka M P, and Taha M R, Int J Impact Eng47 (2019) 39.

Alaboodi A S and Sivasankaran S, J Manuf Process35 (2018) 479.

Wu S, Liu X, Yeung K W K, Liu C, and Yang X, Mater Sci Eng R Rep80 (2014) 1.

Acknowledgements

The corresponding author wishes to thank the Qassim University at Saudi Arabia for all support required to carry out this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Aloyaydi, B.A., Sivasankaran, S. Low-Velocity Impact Characteristics of 3D-Printed Poly-Lactic Acid Thermoplastic Processed by Fused Deposition Modeling. Trans Indian Inst Met 73, 1669–1677 (2020). https://doi.org/10.1007/s12666-020-01952-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01952-6