Abstract

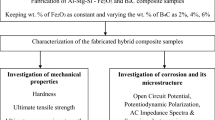

The development of materials having high mechanical strength and corrosion resistance property is of much interest for applications in automobile, defense and marine industries. This research article investigates the electrochemical and mechanical behaviors of B4C/Al–Mg–Si composites fabricated by using the powder metallurgy method. The fabricated composites which consist of 3.5, 7.0 and 10.5 wt% of B4C reinforcement particles showed a uniform distribution. In order to find the effects of corrosion and mechanical properties of the produced composites, potentiodynamic polarization, electrochemical impedance spectroscopy and Vickers micro-hardness (HV) measurements were carried out. The results revealed that the corrosion resistance decreases with the increasing B4C content, while hardness of the composite increases. Additionally, a technique was employed to improve the corrosion resistance as well as hardness of the composite. The results also demonstrate the mechanisms of the corrosion, high hardness and their improvement in the composites

Similar content being viewed by others

References

Macke A, Schultz B, and Rohatgi P, Adv Mater Processes 170 (2012) 19.

Kumar U K A V, Mater Today Proc 4 (2017) 1140.

Singh R, and Singh S, Mater Today Proc 2 (2015) 1876.

Torralba J D, Da Costa C, and Velasco F, J Mater Process Technol 133 (2003) 203.

Xiao M, Chen J, Kang J, Chen K, Wu D, and Gao N, AIP Adv 8 (2018) 095322.

Salih O S, Ou H, Sun W, and McCartney D, Mater Des 86 (2015) 61.

Nardone V, and Prewo K, Scr Mater 20 (1986) 43.

Pitchayyapillai G, Seenikannan P, Raja K, and Chandrasekaran K, Adv Mater Sci Eng 2016.

Imai T, Mabuchi M, Tozawa Y, and Yamada M, J Mater Sci Lett 9 (1990) 255.

Thevenot F, J Eur Ceram Soc 6 (1990) 205.

Petrescu M, Diam Relat Mater 13 (2004) 1848.

Sevak Singh R, Yingjie Tay R, Leong Chow W, Hon Tsang S, Mallick G, and Tong Teo E H, Appl Phys Lett 104 (2014) 163101.

Tay R Y, Wang X, Tsang S H, Loh G C, Singh R S, Li H, Mallick G, and Teo E H T, J Mater Chem 2 (2014) 1650.

Tay R Y, Griep M H, Mallick G, Tsang S H, Singh R S, Tumlin T, Teo E H T, and Karna S P, Nano Lett 14 (2014) 839.

Knowles A, Jiang X, Galano M, and Audebert F, J Alloys Compd 615 (2014) S401.

Stansbury E E, and Buchanan RA, Fundamentals of Electrochemical Corrosion, ASM International, New York (2000).

Trzaskoma P, McCafferty E, and Crowe C, J Electrochem Soc 130 (1983) 1804.

Shimizu Y, Nishimura T, and Matsushima I, Mater Sci Eng A 198 (1995) 113.

Yue T, Yan L, Chan C, Dong C, Man H, and Pang G, Surf Coat Technol 179 (2004) 158.

Alaneme K, J Sci 18 (2011) 55.

Shankar G, Jayashree P, Shetty R, Kini A, Sharma S, Int J Curr Eng Technol 3 (2013) 922.

Williamson G, and Hall W, Acta Metall 1 (1953) 22.

Zhang J, Chen Z, Zhao J, and Jiang Z, Mech Adv Mater Mod Process 4 (2018) 4.

Saheb N, Aliyu I K, Hassan S F, and Al-Aqeeli N, Materials 7 (2014) 6748.

Kumar N, Manoj M K, and Phani M K, Mat Sci Res India 15 (2018) 91.

Jones D A, Principles and Prevention of Corrosion, Macmillan Pub. Co., New York (1992).

Larsen M H, Walmsley J C, Lunder O, Mathiesen R H, and Nisancioglu K, J Electrochem Soc 155 (2008) C550.

Shrivastava V, Gupta G K, and Singh I, J Alloys Compd 775 (2019) 628.

Acknowledgements

The authors would like to acknowledge the department of Metallurgical and Materials Engineering and department of Physics, O P Jindal University, Raigarh, India, for the encouragement and research support. The authors also acknowledge Prof (Dr.) Ayush Khare, department of Physics, National Institute of Technology Raipur, India, for their invaluable and laboratory support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kumar, N., Gautam, A., Singh, R.S. et al. Study of B4C/Al–Mg–Si Composites as Highly Hard and Corrosion-Resistant Materials for Industrial Applications. Trans Indian Inst Met 72, 2495–2501 (2019). https://doi.org/10.1007/s12666-019-01717-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01717-w