Abstract

Iron- and steelmaking processes consume an enormous amount of materials in a large-scale production unit. The overall process consists of the flow of material as well as heat across large number of interconnected unit process reactors. Almost all reactors have deviations from thermodynamic equilibrium in overall sense, but they can be classified as large number of interconnected localized equilibrium reactors with restricted interactions among them. Therefore, the role of thermodynamic package like FactSage [1] and sequential modular-based package like METSIM [2] becomes very important for process design and control as well as for studying the parameters to achieve minimum cost and CO2 emissions. In the paper flow sheet, modeling-based approach with coupled application of METSIM is demonstrated for modeling of blast furnace ironmaking, BOF steelmaking and ladle furnace processes. These processes are demonstrated using the capabilities of METSIM for effective process control.

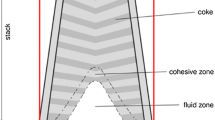

Courtesy: Prof. Robertson4

Similar content being viewed by others

References

FactSage: Center for Research in Chemical Thermodynamics, Polytechique de Montreal, Canada. www.factsage.com.

METSIM. www.metsim.com.

Zheng S S, Du H, Wang S, and Zhang Y, Adv Mater Res 581–82 (2012) 988.

Tripathi N, Coursol P, Kreuh M, Tisdale D, and Mackey P, Advanced Metallurgical Modeling of Ni-Cu Smelting at the Xstrata Nickel Sudbury Smelter, TMS Annual Meeting (2009), p 251.

Chamveha P, Kattiyapon C, Chuachuensuk A, Authayanun S, and Arpornwichanop A, Ind Eng Chem Res 48 (2009) 1120.

Richards V L, Rawlins C H, Lekakh S N, and Peaslee K D, Sequestration of Carbon Dioxide by Steelmaking Slag: Process Phenomena and Reactor Study, TMS Annual Meeting (2008), p 95.

Pistorius P C, and Vermaak M K G, S Afr J Sci 95 (1999) 377.

Deo B, and Boom R, Fundamentals of Steelmaking Metallurgy, Prentice Hall, London (1992) p 39.

Robertson D G C, Deo B, and Ohguchi S, Iron Steelmaking 11 (1984) 41.

Ohguch Si, Robertson D G C, Deo B, Grieveson P, and Jeffes J H E, Ironmaking and Steelmaking 11 (1984) 202.

Robertson D G C, The Computation of the Kinetics of the Reactions Between Multiple Phases in Chemical and Metallurgical Processes, Advanced Steel Refining Technology Symposium, IMRAM, Tohoku University, Sendai (2008), p 1.

Acknowledgement

I wish to acknowledge Prof. D.G.C. Robertson of UMR for his training and guidance about using METSIM. This work was presented in TMS Annual Technical Meeting in 2014 at San Diego. I also would like to acknowledge JSW Steel Ltd., Toranagallu, Bellary, India, for providing the plant data used for validation of some of the models developed in this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shukla, A.K. Thermodynamics-Based Modeling of Iron- and Steelmaking Processes Using Flow Sheet-Based Approach Employing METSIM. Trans Indian Inst Met 72, 767–775 (2019). https://doi.org/10.1007/s12666-018-1529-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1529-z