Abstract

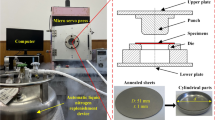

For the purpose of reducing the hook and increasing the effective sheet thickness of the friction stir lap welding joint, a tip-threaded pin was used to weld 3 mm-thick 7075-T6 aluminum alloy in this work. Material flow behavior, joint formation mechanism and lap shear properties of the lap joints were mainly discussed. Results showed that when using the tip-threaded pin, lap joint with nearly aequilate stir zone (SZ) along thickness and rather flat hooks were obtained. When using high rotating speeds, the width of the lower SZ exceeded that of the middle SZ. A void, which resulted from the material loss near the lap interface, was observed at the same time. With increasing the rotating speed, the lap shear failure load of the joint initially increased and then decreased, while the fracture mode changed from tensile fracture to shear fracture mode. The maximum failure load of 17661 N was attained for the joint without void at 850 rpm.

Similar content being viewed by others

References

Ji S, Wang Y, Li Z, Yue Y, and Chai P, Trans Indian Inst Met 70 (2017) 1417.

Zhang ZH, Li WY, Shen JJ, Chao YJ, Li JL, and Ma YE, Mater Des 50 (2013) 551.

Wan L, Huang Y, Wang Y, Lv S, and Feng J, Mater Sci Technol 31 (2015) 1433.

Song YB, Yang XQ, Cui L, Hou XP, Shen ZK, and Xu Y, Mater Des 55 (2014) 9.

Shen ZK, Yang XQ, Zhang ZH, Cui L, and Li TL, Mater Des 44 (2012) 476.

Shi Y, Yue Y, Zhang L, Ji S, and Wang Y, Trans Indian Inst Met 71 (2018) 139.

Ahmed MMZ, Ataya S, El-Sayed Seleman MM, Ammar HR, and Ahmed E, J Mater Process Technol 242 (2017) 77.

Li D, Yang X, Cui L, He F, and Zhang X, J Mater Process Technol 222 (2015) 391.

Babu S, Janaki Ram GD, Venkitakrishnan PV, Reddy GM, and Rao KP, J Mater Sci Technol 28 (2012) 414.

Yue Y, Li Z, Ji S, Huang Y, and Zhou Z, J Mater Sci Technol 32 (2016) 671.

Ji SD, Jin YY, Yue YM, Gao SS, Huang YX, and Wang L, J Mater Sci Technol 10 (2013) 955.

Ma ZY, Mishra RS, and Mahoney MW, Acta Mater 50 (2002) 4419.

Amini S, Amiri MR, and Barani A, Int J Adv Manuf Technol 76 (2015) 255.

Reynolds AP, Scr Mater 58 (2008) 338.

Reilly A, Shercliff H, Chen YC, and Prangnell P, J Mater Process Technol 225 (2015) 473.

Yin YH, Sun N, North TH, and Hu SS, Sci Technol Weld Join 15 (2010) 81.

Badarinarayan H, Shi Y, Li X, and Okamoto K, Int J Mach Tools Manuf 49 (2009) 814.

Cantin GMD, David SA, Thomas WM, Lara-Curzio E, and Babu SS, Sci Technol Weld Join 10 (2005) 268.

Lin YC, Liu JJ, and Chen JN, J Mater Eng Perform 22 (2013) 3674.

Salari E, Jahazi M, Khodabandeh A, and Nanesa HG, Mater Des 58 (2014) 381.

Lin YC, and Chen JN, J Mater Process Technol 225 (2015) 347.

Cederqvist L, and Reynolds AP, Welding 80 (2001) 281.

Liu HJ, Zhao YQ, Hu YY, Chen SX, and Lin Z, Int J Adv Manuf Technol 78 (2015) 1415.

Li Z, Yue Y, Ji S, Chai P, and Zhou Z, Mater Des 90 (2016) 238.

Ji S, and Li Z, J Mater Eng Perform 26 (2017) 921.

Li W, Li J, Zhang Z, Gao D, Wang W, and Dong C, Mater Des 62 (2014) 247.

Li Z, Yue Y, Ji S, Chai P, and Wang L, Mater Des 94 (2016) 368.

Acknowledgements

The author would like to thank Key Laboratory of Fundamental Science for National Defence of Aeronautical Digital Manufacturing Process for performing the experiment of friction stir welding experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Z., Yue, Y., Zhang, W. et al. Interface Behavior and Lap Shear Properties of the 7075-T6 Al FSLW Joint Using a Tip-Threaded Pin. Trans Indian Inst Met 71, 2285–2291 (2018). https://doi.org/10.1007/s12666-018-1360-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1360-6