Abstract

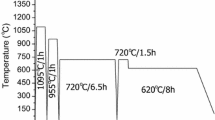

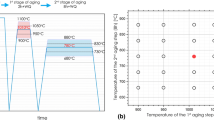

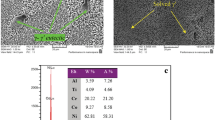

This study consists of assessing the influence of ageing heat treatments on characteristics of the microstructure and the hardness in the Inconel-713C nickel-based superalloy. The ageing process including the time and the temperature was modified based on the material hardness, by the design of experiments (DOE). For this objective, ageing treatments consisted of heating at 850, 890 and 930 °C for 8 and 16 h, after a solutioning treatment. Experimental results showed that the mean hardness reached the highest value (as 43.2 RC) in the sample that was age-hardened at 890 °C for 8 h, without requiring usual double ageing heat treatments. Besides, the DOE also predicted the highest hardness, which would be related to the specimen, hardened at 896.1 °C for 8 h and also 895.3 °C for 16 h, based on vertical and parallel lines, respectively. The highest hardness was associated with the optimum volume fraction (as 64%) of approximately fine size (as 500 nm) of \(\gamma '\) precipitates. Besides, M23C6-type carbides plus NbC had a positive effect to enhance the hardness value. X-ray diffraction (XRD) results indicated various phases created in different ageing heat treatments that affected the hardness.

Similar content being viewed by others

References

Salk N, and Schneider S, Metal injection moulding of Inconel 713C for turbocharger applications, Powder Inject Moul Int 5(3) (2011) 45.

Matysiak H, Zagorska M, Balkowiec A, Adamczyk-Cieslak B, Cygan R, Cwajna J, Nawrocki J, and Kurzydlowski K J, The microstructure degradation of the IN 713C nickel-based superalloy after the stress rupture tests, J Mater Eng Perform 23(9) (2014) 3305.

Shi Z X, Dong J X, Zhang M C, and Zheng L, Solidification characteristics and hot tearing susceptibility of Ni-based superalloys for turbocharger turbine wheel, Trans Nonferrous Met Soc China 24 (2014) 2737.

Boutarek N, Saidi D, Acheheb M A, Iggu M, and Bouterfaia S, Competition between three damageing mechanisms in the fractured surface of an Inconel 713 superalloy, Mater Charact 59 (2008) 951.

Kunz L, Lukas P, and Konecna R, High-cycle fatigue of Ni-base superalloy Inconel 713LC, Int J Fatigue 32 (2010) 908.

Azadi M, and Azadi M, Evaluation of high-temperature creep behavior in Inconel-713C nickel based superalloy considering effects of stress levels, Mater Sci Eng A 689 (2017) 298.

Azadi M, Iziy M, Marbout A, Azadi M, and Hajiali Mohammadi A, Optimization of solution temperature and time in nickel-based superalloy of engine turbo-charger based on hardness by design of experiment, J Engine Res 43 (2016) 63.

Binczyk F, and Sleziona J, Macro- and micro-hardness of IN-713C nickel superalloy constituents, Arch Foundry Eng 9(4) (2009) 9.

Ges A, Palacio H, and Versaci R, IN-713C Characteristic properties optimized through different heat treatments, J Mater Sci 29 (1994) 3572.

Zupanic, Boncina T, Krizman A, and Tichelaar F D, Structure of continuously cast Ni-based superalloy Inconel 713C, J Alloys Compd 329 (2001) 290.

Jonsta P, Jonsta a Z, Sojkaa J, Cizek L, and Hernas A, Structural characteristics of nickel super alloy Inconel 713LC after heat treatment, J Achiev Mater Manuf Eng 21(2) (2007) 29.

Binczyk F, and Sleziona J, Macro-structure of IN-713C superalloy after volume modification, Arch Foundry Eng 9(2) (2009) 105.

Binczyk F, and Sleziona J, Phase transformations and microstructure of IN-713C nickel superalloy, Arch Foundry Eng Vol. 9(2) (2009) 109.

Binczyk F, and Sleziona J, Effect of modification on the mechanical properties of IN-713C alloy, Arch Foundry Eng 10(1) (2010) 195.

Binczyk F, Sleziona J, Szymszalana J, and Gradon P, Effect of technological parameters on structure of castings made from IN-713C nickel alloy, Arch Foundry Eng 11(4) (2011) 9.

Szeliga D, Kubiak K, Cygan R, and Ziaja W, Application of silicon carbide chills in controlling the solidification process of casts made of IN-713C Nickel superalloy, Arch Foundry Eng 12(2) (2012) 105.

Binczyk F, and Gradon P, Analysis of solidification parameters and macrostructure of IN-713C castings after complex modification, Arch Foundry Eng 13(3) (2013) 5.

Montgomery D C, Design and Analysis of Experiments, Wiley, New York (2012).

Chamanfar A, Sarrat L, Jahazi M, Asadi M, Weck A, and Koul A K, Microstructural characteristics of forged and heat treated Inconel-718 disks, Mater Des 52 (2013) 791.

Lachowicz M, Dudzinski W, Haimann K, and Podrez-Radziszewska M, Microstructure transformations and cracking in the matrix of \(\frac{\gamma }{\gamma '}\) superalloy Inconel 713C melted with electron beam, Mater Sci Eng A 479 (2008) 269.

McLean D, Predicting growth of \(\gamma '\) in nickel alloys, Met Sci 18 (1984) 249.

Jia C L, Ge C C, and Yan Q Z, Microstructure evolution and mechanical properties of disk superalloy under multiplex heat treatment, Mater Sci Eng A 659 (2016) 287.

Chiou M S, Jian S R, Yeh A C, Kuo C M, and Juang J Y, High temperature creep properties of directionally solidified CM-247LC Ni-based superalloy, Mater Sci Eng A 655 (2016) 237.

Li H Y, Song X P, Wang Y L, and Chen G L, Coarsening and age hardening behaviors of \(\gamma '\) particles in GH742 during high temperature treatment, J Iron Steel Res 16 (2009) 81.

Zhao S, Xie X., Smith G D, and Patel S J, Gamma prime coarsening and age-hardening behaviors in a new nickel base superalloy, Mater Lett 58 (2004) 1784.

Yan J, Gu Y, Sun F, Xu Y, and Lu J, Microstructural evolution and deformation behavior of a Fe-Ni base superalloy during ageing, J Alloys Compd 694 (2017) 739.

Kuo C M, Yang Y T, Bor H Y, Wei C N, and Tai C C, Ageing effects on the microstructure and creep behavior of Inconel 718 superalloy, Mater Sci Eng A 510–511 (2009) 289.

Wu Q, Song H, Swindeman R W, Shingledecker J P, and Vasudevan V K, Microstructure of long-term aged IN617 Ni-base superalloy, Metall Mater Trans A 39 (2008) 2569.

Feng K Y, Liu P, Li H X, and Li J N, Microstructure and phase transformation on the surface of Inconel 718 alloys fabricated by SLM under 1050°C solid solution + double ageing, Vacuum 145 (2017) 112.

Azadi M, Marbout A, Safarloo S, Azadi M, Shariat M, and Rizi M H, Effects of solutioning and ageing treatments on properties of Inconel-713C nickel-based superalloy under creep loading, Mater Sci Eng A 711 (2018) 195.

Azadi M, Iziy M, Marbout A, Azadi M, and Rizi M H, Investigation of heat treatment effect on microstructures and phases of Inconel-713C superalloy, Inter J Eng Trans A: Basics 30(10) (2017) 1538.

Wen D X, Lin Y C, Chen J, Chen X M, Zhang J L, Liang Y J, and Li L T, Work-hardening behaviors of typical solution-treated and aged Ni-based superalloys during hot deformation, J Alloys Compd 618 (2015) 372.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Safarloo, S., Loghman, F., Azadi, M. et al. Optimal Design Experiment of Ageing Time and Temperature in Inconel-713C Superalloy Based on Hardness Objective. Trans Indian Inst Met 71, 1563–1572 (2018). https://doi.org/10.1007/s12666-018-1291-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1291-2