Abstract

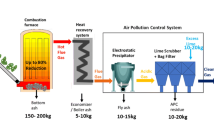

The ash formation behaviour and associated compositional characteristics of the combustion of shoe manufacturing waste (SMW) in a 2.5 MWth pilot-scale circulating fluidized bed combustor (CFBC) were investigated to better understand the combustion behaviour and to find effective management strategy for the disposal of the ash streams produced. The compositional characterisations for the ashes produced from the pilot demonstrations showed the presence of a variety of trace heavy metals both in the fly ash and bottom ash. A pronounced uneven partitioning behaviour was observed on the distribution of these heavy metals between the fly ash and bottom ash, and it was found that all the heavy metals except chromium were preferentially enriched in the fly ash, with the contents of lead and cadmium in the fly ash being over 11 and 6 times higher than in the bottom ash. Leaching tests demonstrated that the concentrations of most of the aforementioned metals present in the leachates from the fly ash and bottom ash could meet the permissible limits for landfill disposal but with lead as an exception with its concentration in the fly ash leachates being over 2 times higher than the limit. The total PCDD and PCDF contents both in the fly ash and bottom ash were also much below the legal limit. To further understand the ash behaviour, the slagging and fouling tendency during SMW combustion in the CFBC was examined by use of the characterisation of the ash mineralogy and the results indicated that the SMW ash likely had low tendencies for slagging and fouling. The best two valorization routes for the SMW bottom ash and fly ash were recommended, one being to use them to produce colloidal silica medium to obtain safe inert filler and the other being to use them as the raw materials in the cement industry.

Graphic Abstract

Similar content being viewed by others

References

Rahimifard, S., Staikos, T., Coates, G.: Recycling of footwear products. A position paper prepared by the Centre for Sustainable Manufacturing and Reuse/Recycling Technologies (SMART). Loughborough University, Leicestershire (2007). http://www.centreforsmart.co.uk/system/downloads/attachment s/000/000/002/original/Footw ear_recyc ling_posit ion_paper.pdf

Chinese Statistics Yearbook Compiling Committee: Chinese Statistics Yearbook 2006. Chinese Statistics Press, Beijing (2006)

Chinese Statistics Yearbook Compiling Committee: Chinese Statistics Yearbook 2016. Chinese Statistics Press, Beijing (2016)

Staikos, T., Rahimifard, S.: A decision-making model for waste management in the footwear industry. Int. J. Prod. Res. 45, 4403–4422 (2007)

Tatàno, F., Acerbi, N., Monterubbiano, C., et al.: Shoe manufacturing wastes: characterisation of properties and recovery options. Resour. Conserv. Recycl. 66, 66–75 (2012)

Lee, M.J., Rahimifard, S.: An air-based automated material recycling system for postconsumer footwear products. Resour. Conserv. Recycl. 69, 90–99 (2012)

Lopes, D., Ferreira, M.J., Russo, R., et al.: Natural and synthetic rubber/waste—ethylene-vinyl acetate composites for sustainable application in the footwear industry. J. Clean. Prod. 92, 230–236 (2015)

Rodrigues, R., Marcilio, N.R., Trierweiler, J.O., et al.: Cogasification of footwear leather waste and high ash coal: a thermodynamic analysis. In: 27th Annual International Pittsburgh Coal Conference (2010)

Sekaran, G., Swarnalatha, S., Srinivasulu, T.: Solid waste management in leather sector. J. Des. Manuf. Technol. 1(1), 47–52 (2007)

Swarnalatha, S., Srinivasulu, T., Srimurali, M., et al.: Safe disposal of toxic chrome buffing dust generated from leather industries. J. Hazard. Mater. 150(2), 290–299 (2008)

Liu, J., Zeng, J., Sun, S., et al.: Combined effects of FeCl3 and CaO conditioning on SO2, HCl and heavy metals emissions during the DDSS incineration. Chem. Eng. J. 299, 449–458 (2016)

Luan, J., Li, R., Zhang, Z., et al.: Influence of chlorine, sulfur and phosphorus on the volatilization behavior of heavy metals during sewage sludge thermal treatment. Waste Manag. Res. 31(10), 1012–1018 (2013)

Li, L., Yu, C., Bai, J., et al.: Heavy metal characterization of circulating fluidized bed derived biomass ash. J. Hazard. Mater. 233, 41–47 (2012)

Peng, T.H., Lin, C.L., Wey, M.Y.: Study of the low-temperature two-stage fluidized bed incineration: influence of the second-stage sand bed operating conditions on pollutant emission. Appl. Therm. Eng. 75, 592–599 (2015)

Samaksaman, U., Peng, T.H., Kuo, J.H., et al.: Thermal treatment of soil co-contaminated with lube oil and heavy metals in a low-temperature two-stage fluidized bed incinerator. Appl. Therm. Eng. 93, 131–138 (2016)

Girón, R.P., Ruiz, B., Fuente, E., et al.: Properties of fly ash from forest biomass combustion. Fuel 114, 71–77 (2013)

Freire, M., Lopes, H., Tarelho, L.A.C.: Critical aspects of biomass ashes utilization in soils: composition, leachability, PAH and PCDD/F. Waste Manag. 46, 304–315 (2015)

Saqib, N., Bäckström, M.: Trace element partitioning in ashes from boilers firing pure wood or mixtures of solid waste with respect to fuel composition, chlorine content and temperature. Waste Manag. 34(12), 2505–2519 (2014)

Margallo, M., Taddei, M.B.M., Hernández-Pellón, A., et al.: Environmental sustainability assessment of the management of municipal solid waste incineration residues: a review of the current situation. Clean Technol. Environ. 17(5), 1333–1353 (2015)

Zhang, Q., Liu, H., Qian, Y., et al.: The influence of phosphorus on ash fusion temperature of sludge and coal. Fuel Process. Technol. 110, 218–226 (2013)

Rendek, E., Ducom, G., Germain, P.: Influence of waste input and combustion technology on MSWI bottom ash quality. Waste Manag. 27(10), 1403–1407 (2007)

Folgueras, M.B., Alonso, M., Folgueras, J.R.: Modification of lignite ash fusion temperatures by the addition of different types of sewage sludge. Fuel Process. Technol. 131, 348–355 (2015)

Folgueras, M.B., Alonso, M., Folgueras, J.R.: Effect of sludge addition to coal on Na, K and S volatilisation in ashing process and ash fusibility. Fuel Process. Technol. 138, 714–723 (2015)

Ferreira, P.T., Ferreira, M.E., Teixeira, J.C.: Analysis of industrial waste in wood pellets and co-combustion products. Waste Biomass Valoriz. 5(4), 637–650 (2014)

Kupka, T., Mancini, M., Irmer, M., et al.: Investigation of ash deposit formation during co-firing of coal with sewage sludge, saw-dust and refuse derived fuel. Fuel 87(12), 2824–2837 (2008)

Niu, Y., Tan, H., Hui, S.: Ash-related issues during biomass combustion: alkali-induced slagging, silicate melt-induced slagging (ash fusion), agglomeration, corrosion, ash utilization, and related countermeasures. Prog. Energ. Combust. 52, 1–61 (2016)

Tang, J., Steenari, B.M.: Leaching optimization of municipal solid waste incineration ash for resource recovery: a case study of Cu, Zn, Pb and Cd. Waste Manag. 48, 315–322 (2016)

Kovacs, H., Szemmelveisz, K., Koós, T.: Theoretical and experimental metals flow calculations during biomass combustion. Fuel 185, 524–531 (2016)

Jenkins, B.M., Baxter Jr., L.L., Miles, T.R., et al.: Combustion properties of biomass. Fuel Process. Technol. 54(1–3), 17–46 (1998)

Nagib, S., Inoue, K.: Recovery of lead and zinc from fly ash generated from municipal incineration plants by means of acid and/or alkaline leaching. Hydrometallurgy 56(3), 269–292 (2000)

Schlumberger, S., Schuster, M., Ringmann, S., et al.: Recovery of high purity zinc from filter ash produced during the thermal treatment of waste and inerting of residual materials. Waste Manag. Res. 25(6), 547–555 (2007)

Wang, T., Xue, Y., Zhou, M., et al.: Comparative study on the mobility and speciation of heavy metals in ashes from co-combustion of sewage sludge/dredged sludge and rice husk. Chemosphere 169, 162–170 (2016)

Verma, S.K., Masto, R.E., Gautam, S., et al.: Investigations on PAHs and trace elements in coal and its combustion residues from a power plant. Fuel 162, 138–147 (2015)

Ram, L.C., Masto, R.E., Srivastava, N.K., et al.: Potentially toxic elements in lignite and its combustion residues from a power plant. Environ. Monit. Assess. 187(1), 4148 (2015)

McKay, G.: Dioxin characterisation, formation and minimisation during municipal solid waste (MSW) incineration. Chem. Eng. J. 86(3), 343–368 (2002)

Sjaak, V., Koppejan, J.: The handbook of biomass combustion and co-firing, vol. 144. Earthsacn, Washington, DC (2008)

Zhou, H., Meng, A., Long, Y., et al.: A review of dioxin-related substances during municipal solid waste incineration. Waste Manag. 36, 106–118 (2015)

Ryu, J.Y., Mulholland, J.A., Takeuchi, M., et al.: CuCl2-catalyzed PCDD/F formation and congener patterns from phenols. Chemosphere 61(9), 1312–1326 (2005)

Jiang, H., Liu, J., Han, W.: The status and developments of leather solid waste treatment: a mini-review. Waste Manag. Res. 34(5), 399–408 (2016)

Liu, C., Huang, Y., Dong, L., et al.: Combustion characteristics and pollutants in the flue gas during shoe manufacturing waste combustion in a 2.5 Mwth pilot-scale circulating fluidized bed. Waste Biomass Valoriz. (2018). https://doi.org/10.1007/s12649-018-0476-6

Duan, L., Sun, H., Jiang, Y., et al.: Partitioning of trace elements, As, Ba, Cd, Cr, Cu, Mn and Pb, in a 2.5 MWth pilot-scale circulating fluidised bed combustor burning an anthracite and a bituminous coal. Fuel Process. Technol. 146, 1–8 (2016)

General rules for inductively coupled plasma-atomic emission spectrometry (JY/T 015-1996). State Education Commission of China, Beijing, China (1996) (in Chinese)

Fan, M., Brown, R.C.: Comparison of the loss-on-ignition and thermogravimetric analysis techniques in measuring unburned carbon in coal fly ash. Energy Fuel 15(6), 1414–1417 (2001)

Chen, Q., Ke, Y., Zhang, L., et al.: Application of accelerated carbonation with a combination of Na2CO3 and CO2 in cement-based solidification/stabilization of heavy metal-bearing sediment. J. Hazard. Mater. 166(1), 421–427 (2009)

Li, J., Dong, H., Sun, J., et al.: Composition profiles and health risk of PCDD/F in outdoor air and fly ash from municipal solid waste incineration and adjacent villages in East China. Sci. Total Environ. 571, 876–882 (2016)

Li, F.H., Huang, J.J., Fang, Y.T., et al.: The effects of leaching and floatation on the ash fusion temperatures of three selected lignites. Fuel 90(7), 2377–2383 (2011)

Blanc, D., Gonzalez, L., Lupsea-Toader, M., et al.: Mineralogical evolution and leaching behaviour of a heap of bottom ash as a function of time: influence on its valorization. Waste Biomass Valoriz. 9, 1–11 (2018)

Identification standards for hazardous waste-identification for extraction toxicity (GB5085.3-2007). General Administration of Quality Supervision, Inspection and Quarantine of China and Ministry of Environmental Protection of China, Beijing, China (2007) (in Chinese)

Standard for pollution control on the landfill site of municipal solid waste (GB 16889-2008). Ministry of Environmental Protection of China, Beijing, China (2008) (in Chinese)

Vassileva, S., Christina, G., Vassileva, C., et al.: An overview of the composition and application of biomass ash. Part 1. Phase-mineral and chemical composition and classification. Fuel 105, 40–76 (2013)

Vassilev, S., Baxter, D., Andersen, L., et al.: An overview of the composition and application of biomass ash. Part 2. Potential utilisation, technological and ecological advantages and challenges. Fuel 105, 19–39 (2013)

Quina, M.J., Bontempi, E., Bogush, A., et al.: Technologies for the management of MSW incineration ashes from gas cleaning: new perspectives on recovery of secondary raw materials and circular economy. Sci. Total Environ. 635, 526–542 (2018)

Trivedi, N.S., Mandavgane, S.A., Chaurasia, A.: Characterization and valorization of biomass char: a comparison with biomass ash. Environ. Sci. Pollut. Res. Int. 25(4), 3458–3467 (2017)

Trivedi, N.S., Mehtre, S., Kulkarni, B.D., et al.: Characterization and valorization of biomass ashes. Environ. Sci. Pollut. Res. 23(20), 1–14 (2016)

Bontempi, E.: A new approach for evaluating the sustainability of raw materials substitution based on embodied energy and the CO2 footprint. J. Clean. Prod. 162, 162–169 (2017)

Acknowledgements

The authors gratefully acknowledge the support from the National Key R&D Program of China (2018YFB0605102), National Natural Science Foundation of China (No. 51676040), Jiangsu Natural Science Foundation of China (BK20181281), the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (17KJB470007), the Scientific Foundation of Nanjing Institute of Technology (YKJ201609) and the Key Research and Development Program of Zhenjiang (SH2018014). The authors would also like to acknowledge the provision of a scholarship to Mr. Changqi Liu by the China Scholarship Council (CSC) which enables him to be able to complete part of the reported work at the University of Nottingham.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Niu, M., Liu, C., Wang, X. et al. Chemical Characteristics of Ash Formed from the Combustion of Shoe Manufacturing Waste in a 2.5 MWth Circulating Fluidized Bed Combustor. Waste Biomass Valor 11, 4551–4560 (2020). https://doi.org/10.1007/s12649-019-00733-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00733-7