Abstract

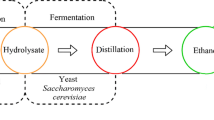

Algae are considered as a good substrate for bioethanol production. This study was carried out to evaluate the potential chemical and biological hydrolysis of the macrogreen alga Ulva fasciata and the microgreen alga Chlorella vulgaris to pretreatment of cell wall and sugar production. Different concentrations of reduced sugar extracted from U. faciata was studied to obtain the maximum amount of bioethanol. Saccharomyces cerevisiae SH02, Pseudomonas sp. SH03, were used to determine the best microorganisms that affect in fermentation process and hence the production of bioethanol. U. fasciata contains maximum amount of sugar. Chemical hydrolysis is the best methods for pretreatment of algae. S. cerevisiae SH02 was the best microorganisms for fermentation process with sugar obtained from U. faciata by chemical hydrolysis. The highest ethanol production by S. cerevisiae SH02 was 40% with 5% sugar concentration that produced by acid hydrolysis and with increasing sugar ratio ethanol production decrease. The highest ethanol yield with Pseudomonas sp. SH03 was 22% obtained by fermentation of 5% algal sugar.

Similar content being viewed by others

References

Goh, S.C., Tab, K.T., Lee, K.T., Bhatia, S.: Bio-ethanol from lignocellulose: status, perspectives and challenges in Malaysia. Bioresour. Technol. 101, 4834–4841 (2009)

Harun, R., Danquah, M.K., Forde, G.M.: Microalgal biomass as a fermentation feedstock for bioethanol production. J. Chem. Technol. Biotechnol. 2, 199–203 (2009)

Chisti, Y.: Biodiesel from microalgae. Biotechnol. Adv. 25, 294–306 (2007)

Singh, A., Nigam, P.S., Murphy, J.D.: Mechanism and challenges in commercialisation of algal biofuels. Bioresour. Technol. 102, 26–34 (2010)

Lundquist, T.J., Woertz, I.C., Quinn, N.W.T., Benemann, J.R.: A Realistic Technology and Engineering Assessment of Algae Biofuel Production. Energy Biosciences Institution, Berkeley (2010)

Wi, S.G., Kim, H.J., Mahadevan, S.A., Yang, D.J., Bae, H.J.: The potential value of the seaweed Ceylon moss (Gelidium amansii) as an alternative bioenergy resource. Bioresour. Technol. 100, 6658–6660 (2009)

Lahaye, M., Kaeffer, B.: Seaweed dietary fibres: structure, physico-chemical and biological properties relevant to intestinal physiology. Sci. Aliments 17, 563–584 (1997)

Hirano, A., Ueda, R., Hirayama, S., Ogushi, Y.: CO2 fixation and ethanol production with micro algal photosynthesis and intracellular anaerobic fermentation. Energy 22, 137–142 (1997)

Simpson, A.J., Kingery, W.L., Hatcher, P.G.: The identification of plant derived structures in humic materials using three-dimensional NMR spectroscopy. Environ. Sci. Technol. 37, 337–342 (2003)

Sveinsdottir, M., Baldursson, S.R.B., Orlygsson, J.: Ethanol production from monosugars and lignocellulosic biomass by thermophilic bacteria isolated from Icelandic hot springs. Icel. Agric. Sci. 22, 45–58(2009)

Ranjan, A., Singh, P.: Comperative study of bioethanol production ability of Bacillus subtilis and Sacchromyces cerevisiae using banana and orange peels. Int. J. Sci. Eng. Res. 5–1, 2229–5518 (2014)

Xiong, L., Maki, M., Guo, Z., Mao, C., Qin, W.: Agave biomass is excellent for production of bioethanol and xylitol using Bacillus strain 65S3 and Pseudomonas strain CDS3. J. Biobased Mater. Bioenergy 8, 1–7 (2014)

Taylor, W.S.: Marine Algae of the Eastern Tropical and Subtropical Coasts of Americas. The University of Michigan Press, Ann Arbor (1985)

Kuhl, A., Lorenzen, H.: Handling and culturing of Chlorella. In: Prescott, D.M. (ed.) Methods in cell physiology, vol. 1, pp. 152–187. Academic Press, London (1964)

Sharma, R., Singh, G.P., Sharma, V.K.: Comparison of different media formulations on growth, morphology and chlorophyll content of green algae Chlorella vulgaris. Int. J. Pharm. Biol. Sci. 2(2), 509–516 (2011)

Sherif, S.A.: Genetic and molecular studies on bioethanol production by certain microorganisms grown on algal sugar. Thesis Botany Department Faculty of Science Menofiya University Egypt (2015)

Krishnaveni, S., Balasubramanian, T., Sadasivam, S.: Sugar distribution in sweet stalk sorghum. Food. Chem. 15, 229–232 (1984)

Ausubel, F.M., Brent, R., Kingston, R.E., Moore, D.D., Seidman, J.G., Smith, J.A., Struhl, K.: Current Protocols in Molecular Biology. Current Protocols Brooklyn, New York (1994)

Hamouda, A.R., Sherif, S.A., Dawoud, G.T.M., Ghareeb, M.M.: Enhancement of bioethanol production from Ulva fasciata by biological and chemical saccharification. Rend. Lincei Sci. Fis. Nat. 27, 665–672 (2016)

Gunasekaran, P., Karunakaran, T., Kasthuribal, M.: Fermentation pattern of Zymomonas mobilis strains on different substrates a comparative study. J. Biosci. 10, 181–186 (1986)

Wei, N., Quarterman, J., Jin, Y.S.: Marine macroalgae: an untapped resource for producing fuels and chemicals. trends. Biotechnology. 31, 70–77 (2013)

Mosier, N., Wyman, C., Dale, B., Elander, R., Lee, Y.Y., Holtzapple, M., Ladisch, M.: Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour. Technol. 96, 673–686 (2005)

Pengzhan, Y., Quanbin, Z., Ning, L., Zuhong, X., Yanmei, W., Zhien, L.: Polysaccharides from Ulva pertusa (Chlorophyta) and preliminary studies on their antihyperlipidemia activity. Appl. Phycol. 15, 21–27(2003)

Lenihan, P., Orozco, A.O., Neill, E., Ahmad, M. N.M., Rooney, D.W., Walker, G.M.: Dilute acid hydrolysis of lignocellulosic biomass. Chem. Eng. J. 156, 395–403 (2010)

Nokov, N., Marinova, M., Dimitrova-konaklieve, S.: Chemical composition and biology of Black sea seaweed Ulva rigida Ag. Part 1. Formatriya (Sofia) 34, 24–26 (1984)

Knoshaug, E.P., Darzins, A.: Algal biofuels. the process. Chem. Eng. Prog. 107, 37–47 (2011)

Tahir, A., Afta, M., Farasat, T.: Effect of cultural conditions on ethanol production by locally isolated Saccharomyces cerevisiae BIO-07. J. Appl. Pharmacol. 3, 72–78 (2010)

Fakroddin, M.D., Abdul Quayum, M.D., Monzurmorsned, A., Naiyyum, C.: Analysis of key factors affecting ethanol production by Saccharomyces cerevisiae IFST-072011. Biotechnology 11, 248–252 (2012)

Kumar, R.S., Shankar, T., Anandapandian, K.T.K: Characterization of alcohol resistant yeast Saccharomyces cerevisiae isolated from Toddy. Int. Res. J. Microbiol. 2, 399–405 (2011)

Govindaswamy, S., Vane, L.M.: Multi-stage continuous culture fermentation of glucose-xylose mixtures to fuel ethanol using genetically engineered Saccharomyces cerevisiae 424S. Bioresour. Technol. 101, 1277–1284 (2010)

Mariam, I., Manzoor, K., Sikander, A.: Enhanced production of ethanol from free and immobilized Saccharomyces cerevisiae under stationary culture. Pak. J. Bot. 41, 21–833 (2009)

Gomaa, E.Z.: Bioconversion of orange peels for ethanol production using Bacillus subtilis and Pseudomonas aeruginosa. Afr. J. Microbiol. Res. 7, 1266–1277 (2013)

Atiyeh, H., Duvnjak, Z.: Production of fructose and ethanol from cane molasses using Saccharomyces cerevisiae ATCC 36858. Acta Biotechnol. 23, 37–48 (2001)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hamouda, R.A., Sherif, S.A. & Ghareeb, M.M. Bioethanol Production by Various Hydrolysis and Fermentation Processes with Micro and Macro Green Algae. Waste Biomass Valor 9, 1495–1501 (2018). https://doi.org/10.1007/s12649-017-9936-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-9936-7