Abstract

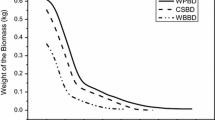

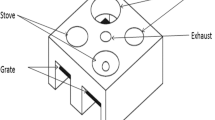

In this study, SPRERI gasifier stove and double pot improved household cookstove were tested with Jatropha shell. Thermal performance and pollutant emissions during water boiling test were evaluated. Jatropha shell combust properly in SPRERI gasifier stove and thermal efficiency was recorded about 31.10%. In case of double pot improved cookstove mixed fuel (1:1) Jatropha shell and babul wood was used for testing and its thermal efficiency was about 22.88%. Lower pollutant emissions were recorded in double pot improved cookstove as compared to SPRERI gasifier stove. Developed stove have acceptable durability, affordable cost, and meet needs of domestic energy requirement. Results of this study may be useful for improving the design of existing stoves and for developing new stove designs. Implications of better agro residue based cookstoves are improved human health, reduced fuel use, reduced deforestation, and reduced global climate change, apart from recovery energy from such agro residues which are not used as animal feed and are disposed off under non-hygienic conditions.

Similar content being viewed by others

Abbreviations

- η:

-

Efficiency of cookstove (%)

- M:

-

Total quantity of water heated at desired temperature (90°C) in kg, excluding the quantity of water heated in the last pot = (No. of pots of water heated × quantity of water used each time in kg)

- Cp :

-

Specific heat of the water (1 kcal/kg)

- Tx :

-

Maximum temperature at which water was heated, (i.e. 90°C)

- Tw :

-

Initial temperature of water (°C)

- m:

-

Quantity of water taken in last pot (kg)

- Tb :

-

Highest temperature of water attained in the last pot (°C)

- M1 :

-

Total amount of water evaporated (kg)

- H:

-

Latent heat of vaporization (586.4359 kcal/kg)

- W:

-

Amount of fuel burnt (kg)

- Hc :

-

Calorific value of the fuel used (wood/briquette) (kcal/kg)

References

Saxena, R.C., Adhikari, D.K., Goyal, H.B.: Biomass-based energy fuel through biochemical routes: a review. Renew. Sustain. Energy Rev. 13, 167–178 (2009)

Putun, A.E., Ozcan, A., Gercel, H.F., Putun, E.: Production of biocrudes from biomass in a fixed bed tubular reactor; product yields and compositions. Fuel 80, 1371–1378 (2001)

Faaji, A.: Modern biomass conversion technologies. Mitig. Adapt. Strateg. Glob. Change 11, 343–375 (2006)

Journey to forever http://journeytoforever.org/at_woodfire.html. Accessed 7 May 2009

Smith, K.R., Uma, R., Kishore, V.V.N., Zhang, J., Joshi, V., Khalil, M.A.K.: Greenhouse implications of household stoves: an analysis for India. Annu. Rev. Energy Environ. 25, 741–763 (2000)

Kituyi, E., Marufu, L., Wandiga, S.O., Jumba, I.O., Andreac, M.O., Helas, G.: Carbon monoxide and nitric oxide from biofuel fires in Kenya. Energy Conserv. Manage. 42, 1517–1524 (2001)

Bahttacharya, S.C., Albina, D.O., Salam, P.A.: Emission factor of wood and charcoal fired cookstoves. Biomass Bioenergy 23, 453–469 (2002)

Belonio, A.T.: Cookstove initiatives on production, promotion and commercialization: the CPU experience. Paper presented at the consultation meeting on the formulation of a national cookstove program held at Silliman University, Dumaguete City, Negros Oriental, 3–5 November 1993

Rathore, N.S., Panwar, N.L., Kurchania, A.K.: Jatropha, Cultivation and Processing Practices. Himanshu Publication, Udaipur (2008)

Singh, R.N., Vyas, D.K., Srivastva, N.S.L., Narra, M.: SPRERI experience on holistic approach to utilize all parts of Jatropha curcas fruit for energy. Renew. Energy 33, 1868–1873 (2008)

ASTM: Annual Book of ASTM Standard. American Society for Testing of Materials, Philadelphia, pp. 19103 (1983)

Singh, R.N., Patil, K.N.: SPRERI method for quick measurement of moisture content of biomass fuels. SESI J. 11(1), 25–28 (2001)

Panwar, N.L., Rathore, N.S.: Design and performance evaluation of a 5 kW producer gas stove. Biomass Bioenergy 33, 1349–1352 (2008)

Panwar, N.L., Kurchania, A.K., Rathore, N.S.: Mitigation of greenhouse gases by adoption of improved biomass cookstoves. Mitig. Adapt. Strateg. Glob. Change 14, 569–578 (2009)

Kishore, V.V.N., Ramana, P.V.: Improved cookstoves in rural India: how improved are they? A critique of the perceive benefit from the national programme on improved chulhas (NIPC). Energy 27, 47–63 (2002)

Online Emission Calculator http://www.abc.net.au/tv/carboncops/calculator.htm. Accessed 7 May 2009

Hossain, M.M.G.: Improved cookstove and biogas programmes in Bangladesh. Energy Sustain. Dev. 7(2), 97–100 (2003)

Reed, T.B., Larson, R.: A wood gas stove for developing countries. Energy Sustain. Dev. III(2), 34–37 (1996)

Uma, R., Lata, K., Kishore, V.V.N., Smith, K.R.: Produce gas as a superior cooking fuel: results of emission and efficiency tests. In: Vankata Raman, P., Srinivas, S.N. (eds.) Proceeding of International Conference on Biomass Energy System. TERI, New Delhi (1997)

Indoor air quality http://store.cleanair4life.com/PDF/IndoorAirQuality_AirQualTestKits.pdf. Accessed 25 Nov 2009

Wood gas camp stove http://www.woodgascampstove.com/Safety.htmlS. Accessed 25 Nov 2009

Smith, K.R.: Health, energy, and greenhouse-gas impact of biomass combustion in household stoves. Energy Sustain. Dev. I(4), 23–29 (1994)

Acknowledgments

The authors are grateful to Indian Council of Agricultural Research, Govt. of India for providing support for this research under All India Coordinated Research Project on Renewable Energy Sources and SPRERI, Vallabh Vidya Nagar for sparing one unit of biomass cookstove for evaluating its performance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Panwar, N.L. Performance Evaluation of Developed Domestic Cook Stove with Jatropha Shell. Waste Biomass Valor 1, 309–314 (2010). https://doi.org/10.1007/s12649-010-9040-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-010-9040-8