Abstract

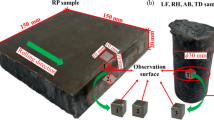

Dual-phase accelerated cooling (DPAC) was applied to X80 pipeline steel to obtain its microstructure with different amounts of bainite and ferrite. The microstructure, hardness, and polarization behaviors of the steel, cooled to different temperatures, were investigated. Results showed that, with decreasing cooling temperature, the amount of polygon ferrite (PF) increased while that of acicular ferrite (AF) decreased. The amount of bainite correspondingly decreased, except when cooled to 760°C. Moreover, the grain size of ferrite increased. The corrosion behaviors of different phases were distinct. Martensite/austenite (M/A) islands presented at the grain boundary of the PF phase caused small pits. Numerous micro-corrosion cells were formed in the AF and bainite phases, where micropores were prone to form. X80 pipeline steel cooled to 700°C had the best corrosion resistance in the simulated seawater. The decreased amount of the PF phase reduced the area of cathode, resulting in slight corrosion. About 40vol% of the bainite phase provided strength while the PF phase provided adequate ductility to the X80 steel. It was concluded that the appropriate cooling temperature was 700°C for ideal corrosion resistance and mechanical properties.

Similar content being viewed by others

References

W.Y. Liu, Y. Ren, H. Gao, S. Zhang, and S. Wang, Research progress and development trend of F-B type high deformability pipeline steel, Wide Heavy Plate, 22(2016), No. 5, p. 25.

N. Ishikawa, N. Shinanai, and J. Kondo, Development of ultra-high strength linepipes with dual-phase microstructure for high strain application, JFE Tech. Rep., 17(2008), p. 26.

J. Ma, X.Y. Zhang, and H.L. Gao, Effects of critical zone accelerated cooling starting temperature on microstructure and mechanical properties of X100 large deformation pipeline steel, Mater. Mech. Eng., 38(2014), No. 9, p. 12.

N. Ishikawa, M. Okatsu, S. Endo, and J. Kondo, Design concept and production of high deformability linepipe, [in] Proceedings of the 6th International Pipeline Conference, Calgary, 2006, p. 215.

S.Y. Wang, H. Yu, T. Zhou, and T. Wang, Effects of nonrecrystallization zone reduction on microstructure and precipitation behavior of a ferrite-bainite dual phase steel, Mater. Des., 88(2015), p. 847.

D.L. Meng, Y.L. Kang, X.F. Zheng, S.Y. An, and D.X. Xia, Effect of two-stage controlled cooling on the microstructure and properties of Mo-containing X80 high-deformability pipeline steel, J. Univ. Sci. Technol. Beijing, 33(2011), No. 7, p. 834.

J. Ma, X.Y. Zhang, S.X. Cheng, and H.L. Gao, Study on microstructure and properties of (B+F) X80 large deformation pipeline steel after critical zone accelerated cooling, Mater. Rev., 28(2014), p. 118.

F. Yu, C.T. Ying, R.G. Wang, H.Y. Liu, X.L. Li, J.G. Cong, and J. Yang, Study on rolling technology for high-strain pipeline steel X80, Angang Technol., 385(2014), No. 1, p. 22.

J. Liu, Research of Enhancement Mechanism of Plasticity of X80 Pipeline Steel [Dissertation], University of Science and Technology Beijing, Beijing, 2015.

W.W. Li, Y.R. Feng, and H.L Gao, Study on the feature of X80 pipeline steel microstructural morphologies, Pet. Instrum., 1(2015), No. 1, p. 36.

H.S. Zhang, Y.L. Kang, D.L. Meng, D.X. Xia, and S.Y. An, Research on processing, microstructure and properties of X80 high-deformability pipelines steel, China Metall., 22(2012), No. 9, p. 10.

Y.C. Zhao, Y.L. Deng, M.C. Huang, and M.C. Zhao, Effect of heat treatment on strengthening level of acicular ferrite pipeline steel, Hot Work. Technol., 38(2009), No. 24, p. 112.

L. Cheng and Y.X. Tan, Investigation on various mi-cro-structure of steel with acicular ferrites, Met. Mater. Metall. Eng., 38(2010), No. 2, p. 11.

P.X. Zhao, X.R. Zuo, K. Chen, L. Yuan, Y.L. Qiu, Z.Z. Zhang, and S.S. Li, Corrosion behavior of X80 pipeline steel with strain-based design, Trans. Mater. Heat Treat., 34(2013), p. 221.

Z.Y. Liu, X.G. Li, and Y.F. Cheng, Understand the occurrence of pitting corrosion of pipeline carbon steel under cathodic polarization, Electrochim. Acta, 60(2012), p. 259.

Z.P. Zhao, G.Y. Qiao, L. Tang, H.W. Zhu, B. Liao, and F.R. Xiao, Fatigue properties of X80 pipeline steels with ferrite/bainite dual-phase microstructure, Mater. Sci. Eng. A, 657(2016), p. 96.

Y.X. Wang, W.M. Zhao, H. Ai, X.G. Zhou, and T.M. Zhang, Effects of strain on the corrosion behaviour of X80 steel, Corros. Sci., 53(2011), No. 9, p. 2761.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51761030 and 51701064) and the Inner Mongolia Natural Science Foundation (No. 2019MS05081).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ma, J., Feng, F., Yu, Bq. et al. Effect of cooling temperature on the microstructure and corrosion behavior of X80 pipeline steel. Int J Miner Metall Mater 27, 347–353 (2020). https://doi.org/10.1007/s12613-019-1882-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1882-x