Abstract

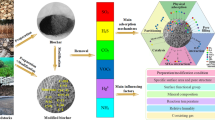

This study explores the key physicochemical factors affecting the hydrophilic characteristics of iron mine blasting dust (BD). The BD is separated into an unwetted part (UWBD, hydrophobic part) and a wetted part (WBD, hydrophilic part). Its particle size, true density (TD), pore parameters, mineral composition, and surface compounds are comprehensively characterized and compared. The results indicate that a smaller particle size and more developed pore parameters are two key factors responsible for the strong hydrophobicity of the BD. The mineral composition of the BD has no direct effect on its wetting properties; however, it indirectly influences the deposition characteristics of the BD in water by affecting its TD. Unlike coal dust, the surface organic composition of the BD does not affect its wettability and the peak area of C-C/C-H hydrophobic groups in the C Is X-ray photoelectron spectrum of the UWBD (45.03%) is smaller than that in the C Is spectrum of the WBD (68.30%). Thus, eleven co-influencing processes of physicochemical properties of the BD on its wettability are summarized. This research sheds light on the key factors affecting the wettability of the BD.

Similar content being viewed by others

References

M. Akbari, G. Lashkaripour, A.Y. Bafghi, and M. Ghafoori, Blastability evaluation for rock mass fragmentation in Iran central iron ore mines, Int. J. Min. Sci. Technol., 25(2015), No. 1, p. 59.

J.G. Liu, L.Z. Jin, J.Y. Wang, S.N. Ou, J.Z. Guo, and T.Y. Wang, Micromorphology and physicochemical properties of hydrophobic blasting dust in iron mines, Int. J. Miner. Metall. Mater., 26(2019), No. 6, p. 665.

J. Csavina, J. Field, M.P. Taylor, S. Gao, A. Landazuri, E.A. Betterton, and A.E. Saez, A review on the importance of metals and metalloids in atmospheric dust and aerosol from mining operations, Sci. Total Environ., 433(2012), p. 58.

B. Wang, C. Wu, L.G. Kang, G. Reniers, and L. Huang, Work safety in China's thirteenth five-year plan period (2016-2020): Current status, new challenges and future tasks, Saf.Sci., 104(2018), p. 164.

P. Gonzales, O. Felix, C. Alexander, E. Lutz, W. Ela, and A.E. Saez, Laboratory dust generation and size-dependent characterization of metal and metalloid-contaminated mine tailings deposits, J. Hazard. Mater, 280(2014), p. 619.

Y.S. Sun, Y.X. Han, Y.F. Li, and Y.J. Li, Formation and characterization of metallic iron grains in coal-based reduction of oolitic iron ore, Int. J. Miner. Metall. Mater, 24(2017), No. 2, p. 123.

G. Zhou, B. Feng, W.J. Yin, and J.Y. Wang, Numerical simulations on airflow-dust diffusion rules with the use of coal cutter dust removal fans and related engineering applications in a fully-mechanized coal mining face, Powder Technol, 339(2018), p. 354.

G. Xu, K.D. Luxbacher, S. Ragab, J.L. Xu, and X.H. Ding, Computational fluid dynamics applied to mining engineering: A review, Int. J. Min. Reclam. Environ., 31(2017), No. 4, p. 251.

M.P. Taylor, S.A. Mould, L.J. Kristensen, and M. Rouillon, Environmental arsenic, cadmium and lead dust emissions from metal mine operations: Implications for environmental management, monitoring and human health, Environ. Res., 135(2014), p. 296.

S.B. Yang, W. Nie, S.S. Lv, Z.Q. Liu, H. Peng, X. Ma, P. Cai, and C.W. Xu, Effects of spraying pressure and installation angle of nozzles on atomization characteristics of external spraying system at a fully-mechanized mining face, Powder Technol., 343(2019), p. 754.

Z.L. Xi, M.M. Jiang, J.J. Yang, and X. Tu, Experimental study on advantages of foam-sol in coal dust control, Process Saf. Environ. Prot, 92(2014), No. 6, p. 637.

G. Xu, Y.P. Chen, J. Eksteen, and J.L. Xu, Surfactant-aided coal dust suppression: A review of evaluation methods and influencing factors, Sci. Total Environ., 639(2018), p. 1060.

D. Omane, W.V. Liu, and Y. Pourrahimian, Comparison of chemical suppressants under different atmospheric temperatures for the control of fugitive dust emission on mine haul's roads, Atmos. Pollut. Res., 9(2018), No. 3, p. 561.

Q. Zhou, B.T. Qin, J. Wang, H.T. Wang, and F. Wang, Effects of preparation parameters on the wetting features of surfactant-magnetized water for dust control in Luwa mine, China, Powder Technol., 326(2018), p. 7.

Y.P. Chen, G. Xu, J.X. Huang, J. Eksteen, X.F. Liu, and Z.D. Zhao, Characterization of coal particles wettability in surfactant solution by using four laboratory static tests, Colloids Surf. A, 567(2019), p. 304.

V.K. Kollipara, Y.P. Chugh, and K. Mondal, Physical, mine-ralogical and wetting characteristics of dusts from Interior Basin coal mines, Int. J. Coal Geol, 127(2014), p. 75.

Q.Z. Li, B.Q. Lin, S. Zhao, and H.M. Dai, Surface physical properties and its effects on the wetting behaviors of respira-ble coal mine dust, Powder Technol., 233(2013), p. 137.

J.G.M.S. Machado, F.A. Brehm, C.A.M. Moraes, C.A. dos Santos, A.C.F. Vilela, and J.B.M. da Cunha, Chemical, physical, structural and morphological characterization of the electric arc furnace dust, J. Hazard. Mater. 136(2006), No. 3, p. 953.

J.B. Zhu and H. Yan, Micro structure and properties of mul-lite-based porous ceramics produced from coal fly ash with added A12O3, Int. J. Miner. Metall. Mater, 24(2017), No. 3, p. 309.

J. Yang, X.K. Wu, J.G. Gao, and G.P. Li, Surface characteristics and wetting mechanism of respirable coal dust, Min. Sci. Technol., 20(2010), No. 3, p. 365.

X.F. Liu, D.Z. Song, X.Q. He, Z.P. Wang, M.R. Zeng, and L.K. Wang, Quantitative analysis of coal nanopore characteristics using atomic force microscopy, Powder Technol., 346(2019), p. 332.

X.Q. He, X.F. Liu, D.Z. Song, and B.S. Nie, Effect of micro-structure on electrical property of coal surface, Appl. Surf. Sci., 483(2019), p. 713.

C.H. Xu, D.M. Wang, H.T. Wang, H.H. Xin, L.Y. Ma, X.L. Zhu, Y. Zhang, and Q.G. Wang, Effects of chemical properties of coal dust on its wettability, Powder Technol., 318(2017), p. 33.

G. Zhou, C.C. Xu, W.M. Cheng, Q. Zhang, and W. Nie, Effects of oxygen element and oxygen-containing functional groups on surface wettability of coal dust with various meta-morphic degrees based on XPS experiment, J. Anal. Methods Chem., 2015, art. No. 467242.

F.G. Fujiwara, D.R. Gomez, L. Dawidowski, P. Perelman, and A. Faggi, Metals associated with airborne particulate matter in road dust and tree bark collected in a megacity (Buenos Aires, Argentina), Ecol. Indie, 11(2011), No. 2, p. 240.

H.T. Wang, L. Zhang, D.M. Wang, and X.X. He, Experimental investigation on the wettability of respirable coal dust based on infrared spectroscopy and contact angle analysis, Adv. Powder. Technol., 28(2017), No. 12, p. 3130.

X.F. Liu, D.Z. Song, X.Q. He, B.S. Nie, and L.K. Wang, Insight into the macromolecular structural differences between hard coal and deformed soft coal, Fuel, 245(2019), p. 188.

G. Oberdorster, E. Oberdorster, and J. Oberdorster, Nanotox-icology: An emerging discipline evolving from studies of ul-trafine particles, Environ. Health Perspect, 113(2005), No. 7, p. 823.

P.L. Walker, E.E. Petersen, and C.C. Wright, Surface active agent phenomena in dust abatement, Ind. Eng. Chem., 44(1952), No. 10, p. 2389.

D.H. Everett and F.S. Stone, The Structure and Properties of Porous Materials, Butterworths, London, 1958.

Y. Tian and L. Jiang, Wetting: Intrinsically robust hydropho-bicity, Nat. Mater, 12(2013), No. 4, p. 291.

X.F. Liu, B.S. Nie, W.X. Wang, Z.P. Wang, and L. Zhang, The use of AFM in quantitative analysis of pore characteristics in coal and coal-bearing shale, Mar. Pet. Geol, 105(2019), p. 331.

X.F. Liu, D.Z. Song, X.Q. He, Z.P. Wang, M.R. Zeng, and L.K. Wang, Nanopore structure of deep-burial coals explored by AFM, Fuel, 246(2019), p. 9.

T. Xu, X.J. Ning, G.W. Wang, W. Liang, J.L. Zhang, Y.J. Li, H.Y. Wang, and C.H. Jiang, Combustion characteristics and kinetic analysis of co-combustion between bag dust and pulverized coal, Int. J. Miner. Metall. Mater, 25(2018), No. 12, p. 1412.

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (No. 2017YFC0805204) and the National Natural Science Foundation of China (Nos. 51874015 and 51504017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Jg., Jin, Lz., Wang, Jy. et al. Co-influencing mechanisms of physicochemical properties of blasting dust in iron mines on its wettability. Int J Miner Metall Mater 26, 1080–1091 (2019). https://doi.org/10.1007/s12613-019-1874-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1874-x