Abstract

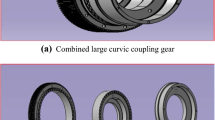

Hot forging is a processing of plastic deformation for the metal at recrystallization temperature or higher. It is possible to decrease the flow stress and energy required to form the material at elevated temperature. But cold forging can improve mechanical properties, excellent dimensional accuracy, and surface quality. Main advantage of hot–cold complex forging is that it is able of large deformation with less force, and improved mechanical properties and dimensional accuracy. In general, complex forging for combining cold forging and hot forging of small bar can improve the shape accuracy of forged parts. In this study, the material loss and the production time were high in the conventional cutting process, but cam ring gear parts of large diameter for truck clutch were developed by applying the hot–cold forging technology. The complex forging technology of cam ring gear parts would be very useful to improve dimensional accuracy, reduce manufacturing cost, and increase die life.

Similar content being viewed by others

References

Park, D. H., & Kwon, H. H. (2016). Development of automobile engine mounting parts using hot–cold complex forging technology. International Journal of Precision Engineering and Manufacturing-Green Technology, 3(2), 179–184.

Park, D. H., & Han, S. C. (2015). Integration forming technology based on cold hot forging of clutch jaw parts for farm machinery. Journal of Korean Society of Manufacturing Technology Engineers, 24(5), 489–495.

Park, S. S., Kim, B. M., & Lee, J. M. (2005). Process design of cold forging for drum clutch with inner tooth component. Journal of the Korean Society of Precision Engineering, 22(2), 30–37.

Park, D. H., Tak, Y. H., & Kang, G. H. (2014). A study on forging technology of oxygen-free copper for electrode body parts of solar light. International Journal of Engineering Science and Innovative Technology, 3(1), 337–343.

Lee, K. O., Kim, J. M., Je, J. S., & Kang, S. S. (2006). Development of precise clutch gear for automobile transmission by compound forging process. Journal of the Korean Society of Precision Engineering, 23(1), 185–192.

Lee, H. S., Kim, T. H., Kim, S. H., Hong, E. C., & Lee, J. H. (2015). A study on the optimum design for energy saving of an auto transmission part. Transactions of Materials Processing, 24(3), 181–186.

Kwon, H. H., Moon, K. J., & Song, S. E. (2010). Forging process analysis of the multi-forging die for the unified universal pipe joint of the intermediate shaft. Journal of the Korean Society of Machine Tool Engineers, 19(1), 33–41.

Song, S. E., & Kwon, H. H. (2012). A study on the cold forging development of guide valve for the fuel pressure regulator. Journal of the Korean Society of Manufacturing Technology Engineers, 21(2), 331–336.

Kang, B. S., & Ku, T. W. (2014). Process modification and numerical simulation for an outer race of a cv joint using multi-stage cold forging. Transactions of Materials Processing, 23(4), 211–220.

Jeon, H. W., Yoon, J. H., Lee, J. H., & Kim, B. M. (2014). Plate forging process design for an under-drive brake piston in automatic transmission. Transactions of Materials Processing, 23(2), 88–94.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Park, DH., Kwon, HD. & Kwon, HH. Development of Cam Ring Gear Parts of Large Diameter for Truck Clutch Using Hot–Cold Complex Forging Technology of Small Bar. Int. J. Precis. Eng. Manuf. 20, 827–836 (2019). https://doi.org/10.1007/s12541-019-00100-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-019-00100-5