Abstract

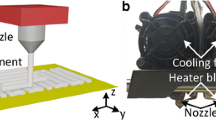

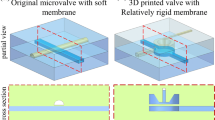

This paper presents design, implementation, and evaluation of a 3D printed miniature peristaltic pump based on a planetary gear structure. The miniature pump (minipump) is printed using a rigid opaque photopolymers (Vero) and the fabrication time for a single pump was in the order of few minutes. The function of the minipump is comparable to that of a benchtop peristaltic pump. It however uses gears instead of rollers to invoke peristalsis. The characterization of the minipump is performed by using deionized water and a honey solution with viscosity of about 170 cP as working fluids. The minipump has a linear flow rate range spanning from 40 mL·min-1 to 230 mL·min-1 and continues working fine even at the backpressure as high as 25 kPa. A temperature gradient microfluidic chip is fabricated as an additional testing platform for the minipump. Our experimental results demonstrate a successful interfacing between the chip and the minipump where the conceptual polymerase chain reaction (PCR) chip is established excellently without leaking or flow disruption within the microchannels. Moreover, the minipump shows good tolerance to bubbles, has a high reproducible output flow, and can operate continuously over a period of 35 hours.

Similar content being viewed by others

References

Woias, P., “Micropumps-Past, Progress and Future Prospects,” Sensors and Actuators B: Chemical, Vol. 105, No. 1, pp. 28–38, 2005.

Pham, M. and Goo, N. S., “Development of a Peristaltic Micropump with Lightweight Piezo-Composite Actuator Membrane Valves,” International Journal Aeronautical and Space Sciences, Vol. 12, No. 1, pp. 69–77, 2011.

Cantwell, M. L., Amirouche, F., and Citerin, J., “Low-Cost High Performance Disposable Micropump for Fluidic Delivery Applications,” Sensors and Actuators A: Physical, Vol. 168, No. 1, pp. 187–194, 2011.

Nguyen, N.-T. and Truong, T.-Q., “A Fully Polymeric Micropump with Piezoelectric Actuator,” Sensors and Actuators B: Chemical, Vol. 97, No. 1, pp. 137–143, 2004.

Wu, M.-H., Wang, H.-Y., Tai, C.-L., Chang, Y.-H., Chen, Y.-M., et al., “Development of Perfusion-Based Microbioreactor Platform Capable of Providing Tunable Dynamic Compressive Loading to 3-D Cell Culture Construct: Demonstration Study of the Effect of Compressive Stimulations on Articular Chondrocyte Functions,” Sensors and Actuators B: Chemical, Vol. 176, pp. 86–96, 2013.

Lee, K. S., Boccazzi, P., Sinskey, A. J., and Ram, R. J., “Microfluidic Chemostat and Turbidostat with Flow Rate, Oxygen, and Temperature Control for Dynamic Continuous Culture, Lab on a Chip, Vol. 11, No. 10, pp. 1730–1739, 2011.

Wu, M.-H., Huang, S.-B., Cui, Z., Cui, Z., and Lee, G.-B., “A High Throughput Perfusion-Based Microbioreactor Platform Integrated with Pneumatic Micropumps for Three-Dimensional Cell Culture,” Biomedical Microdevices, Vol. 10, No. 2, pp. 309–319, 2008.

Ni, J., Wang, B., Chang, S., and Lin, Q., “An Integrated Planar Magnetic Micropump,” Microelectronic Engineering, Vol. 117, pp. 35–40, 2014.

Zhou, Y. and Amirouche, F., “An Electromagnetically-Actuated All-Pdms Valveless Micropump for Drug Delivery,” Micromachines, Vol. 2, No. 3, pp. 345–355, 2011.

Chee, P. S., Arsat, R., Adam, T., Hashim, U., Rahim, R. A., and Leow, P. L., “Modular Architecture of a Non-Contact Pinch Actuation Micropump,” Sensors, Vol. 12, No. 9, pp. 12572–12587, 2012.

Jeong, O. C., Park, S. W., Yang, S. S., and Pak, J. J., “Fabrication of a Peristaltic PDMS Micropump,” Sensors and Actuators A: Physical, Vols. 123-124, pp. 453–458, 2005.

Becker, H. and Gärtner, C., “Polymer Microfabrication Methods for Microfluidic Analytical Applications,” Electrophoresis, Vol. 21, No. 1, pp. 12–26, 2000.

Du, M., Ye, X., Wu, K., and Zhou, Z., “A Peristaltic Micro Pump Driven by a Rotating Motor with Magnetically Attracted Steel Balls,” Sensors, Vol. 9, No. 4, pp. 2611–2620, 2009.

Koch, C., Remcho, V., and Ingle, J., “PDMS and Tubing-Based Peristaltic Micropumps with Direct Actuation,” Sensors and Actuators B: Chemical, Vol. 135, No. 2, pp. 664–670, 2009.

Skafte-Pedersen, P., Sabourin, D., Dufva, M., and Snakenborg, D., “Multi-Channel Peristaltic Pump for Microfluidic Applications Featuring Monolithic PDMS Inlay,” Lab on a Chip, Vol. 9, No. 20, pp. 3003–3006, 2009.

Zhang, X., Chen, Z., and Huang, Y., “A Valve-Less Microfluidic Peristaltic Pumping Method,” Biomicrofluidics, Vol. 9, No. 1, Paper No. 014118, 2015.

Shen, M., Dovat, L., and Gijs, M. A., “Magnetic Active-Valve Micropump Actuated by a Rotating Magnetic Assembly,” Sensors and Actuators B: Chemical, Vol. 154, No. 1, pp. 52–58, 2011.

Paydar, O. H., Paredes, C. N., Hwang, Y., Paz, J., Shah, N. B., and Candler, R. N., “Characterization of 3D-Printed Microfluidic Chip Interconnects with Integrated O-Rings,” Sensors and Actuators A: Physical, Vol. 205, pp. 199–203, 2014.

Hwang, Y., Paydar, O. H., and Candler, R.N., “3D Printed Molds for Non-Planar PDMS Microfluidic Channels,” Sensors and Actuators A: Physical, Vol. 226, pp. 137–142, 2015.

Shallan, A. I., Smejkal, P., Corban, M., Guijt, R. M., and Breadmore, M. C., “Cost-Effective Three-Dimensional Printing of Visibly Transparent Microchips within Minutes,” Analytical Chemistry, Vol. 86, No. 6, pp. 3124–3130, 2014.

Tachibana, H., Saito, M., Shibuya, S., Tsuji, K., Miyagawa, N., Yamanaka, K., and Tamiya, E., “On-Chip Quantitative Detection of Pathogen Genes by Autonomous Microfluidic PCR Platform,” Biosensors and Bioelectronics, Vol. 74, pp. 725–730, 2015.

Gómez-de Pedro, S., Berenguel-Alonso, M., Couceiro, P., Alonso-Chamarro, J., and Puyol, M., “Automatic Microfluidic System to Perform Multi-Step Magneto-Biochemical Assays,” Sensors and Actuators B: Chemical, Vol. 245, pp. 477–483, 2017.

Fernández-Carballo, B. L., McGuiness, I., McBeth, C., Kalashnikov, M., Borrós, S., et al., “Low-Cost, Real-Time, Continuous Flow PCR System for Pathogen Detection,” Biomedical Microdevices, Vol. 18, No. 34, 2016. (DOI: 10.1007/s10544-016-0060-4)

Romoli, L., Tantussi, G., and Dini, G., “Experimental Approach to the Laser Machining of PMMA Substrates for the Fabrication of Microfluidic Devices,” Optics and Lasers in Engineering, Vol. 49, No. 3, pp. 419–427, 2011.

Jiang, X., Shao, N., Jing, W., Tao, S., Liu, S., and Sui, G., “Microfluidic Chip Integrating High Throughput Continuous-Flow PCR and DNA Hybridization For Bacteria Analysis,” Talanta, Vol. 122, pp. 246–250, 2014.

Erickson, D., Sinton, D., and Li, D., “Joule Heating and Heat Transfer in Poly (Dimethylsiloxane) Microfluidic Systems,” Lab on a Chip, Vol. 3, No. 3, pp. 141–149, 2003.

Liao, H.-H., Liao, W., and Yang, Y., “Fabrication and Characterization of Thermo-Pneumatic Peristaltic Micropumps,” Nanotech, Vol. 3, pp. 296–299, 2008.

Shoji, E., “Fabrication of a Diaphragm Micropump System Utilizing the Ionomer-Based Polymer Actuator,” Sensors and Actuators B: Chemical, Vol. 237, pp. 660–665, 2016.

Cazorla, P.-H., Fuchs, O., Cochet, M., Maubert, S., Le Rhun, G., Fouillet, Y., and Defay, E., “A Low Voltage Silicon Micro-Pump Based on Piezoelectric Thin Films,” Sensors and Actuators A: Physical, Vol. 250, pp. 35–39, 2016.

Hashimoto, M., Chen, P.-C., Mitchell, M. W., Nikitopoulos, D. E., Soper, S. A., and Murphy, M. C., “Rapid Pcr in a Continuous Flow Device,” Lab on a Chip, Vol. 4, No. 6, pp. 638–645, 2004.

Fuchiwaki, Y. and Nagai, H., “Study of a Liquid Plug-Flow Thermal Cycling Technique Using a Temperature Gradient-Based Actuator,” Sensors, Vol. 14, No. 11, pp. 20235–20244, 2014.

Ognjanovic, M., Ristic, M., and Živkovic, P., “Reliability for Design of Planetary Gear Drive Units,” Meccanica, Vol. 49, No. 4, pp. 829–841, 2014.

Szita, N., Boccazzi, P., Zhang, Z., Boyle, P., Sinskey, A. J., and Jensen, K. F., “Development of a Multiplexed Microbioreactor System for High-Throughput Bioprocessing,” Lab on a Chip, Vol. 5, No. 8, pp. 819–826, 2005.

Schäpper, D., Stocks, S. M., Szita, N., Lantz, A. E., and Gernaey, K. V., “Development of a Single-Use Microbioreactor for Cultivation of Microorganisms,” Chemical Engineering Journal, Vol. 160, No. 3, pp. 891–898, 2010.

Alam, M. N. H. Z., Pinelo, M., Samanta, K., Jonsson, G., Meyer, A., and Gernaey, K. V., “A Continuous Membrane Microbioreactor System for Development of Integrated Pectin Modification and Separation Processes,” Chemical Engineering Journal, Vol. 167, No. 2, pp. 418–426, 2011.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alam, M.N.H.Z., Hossain, F., Vale, A. et al. Design and fabrication of a 3D printed miniature pump for integrated microfluidic applications. Int. J. Precis. Eng. Manuf. 18, 1287–1296 (2017). https://doi.org/10.1007/s12541-017-0152-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0152-y