Abstract

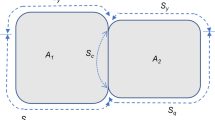

Application of high strength steel is one of the most promising solutions to the problem of vehicle weight reduction. However, weldability problems occur when three sheet metals of the high strength steel are welded. This is because under such situation, the suitable welding range in the lobe diagram is too narrow and the strength between the contact zones is lower than the required value, and also, expulsions between the sheets occur. In this work, a conically shaped hollow electrode was applied at the lower electrode to improve resistance spot weldability of three-sheet welding including high strength steel. Shear strength test and analysis of welding signal and weld cross section were conducted. It was found that the proposed lower electrode has some advantages in welding the three-sheets welding compared with conventional electrodes or hollow electrodes. Consequently, a welding process using the proposed electrode was studied and verified with numerical analysis.

Similar content being viewed by others

References

Jun, J. and Rhee, S., “Study on Spatter Reduction of Resistance Spot Welding of SPRC440 using Hemispherically Concaved Electrode,” Science and Technology of Welding and Joining, Vol. 17, No. 4, pp. 333–337, 2012.

Bowers, R., Sorensen, C., and Eagar, T., “Electrode Geometry in Resistance Spot Welding,” Welding Journal, Vol. 69, No. 2, pp. 45s-51s, 1990.

Choi, Y., Kim, J., Park, Y. W., and Rhee, S., “Development of a Spot Weld Analysis Model that Incorporates Strain Rate,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 2, pp. 245–251, 2012.

Cho, S. M., “Principle of Resistance Welding and Analysis of Monitoring Results,” Journal of KWS, Vol. 15, No. 2, pp. 1–10, 1997.

Miles, M., Hong, S.-T., Woodward, C., and Jeong, Y.-H., “Spot Welding of Aluminum and Cast Iron by Friction Bit Joining,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 6, pp. 1003–1006, 2013.

Choi, D.-Y. and Kim, Y.-G., “Trend of Joining Technology for Automotive Sheet Steels,” Journal of Welding and Joining, Vol. 27, No. 2, pp. 7–12, 2009.

Kim, T., and Rhee, S., “Optimization of Welding Parameters for Resistance Spot Welding of Trip Steel using Response Surface Methodology,” International Journal of Production Reseach, Vol. 43, No. 32, pp. 4643–4657, 2005.

Kim, T., Park, H., and Rhee, S., “A Study of Weldability Evaluation for TRIP Sheet in Resistance Spot Welding,” Journal of KWS, Vol. 1, p. 149–151, 2003.

Kaya, Y. and Kahraman, N., “The Effects of Electrode Force, Welding Current and Welding Time on the Resistance Spot Weldability of Pure Titanium,” The International Journal of Advanced Manufacturing Technology, Vol. 60, No. 1–4, pp. 127–134, 2012.

Oikawa, H., Murayama, G., Hiwatashi, S., and Matsuyama, K., “Resistance Spot Weldability of High Strength Steel Sheets for Automobiles and the Quality Assurance of Joints,” Welding in the World, Vol. 51, No. 3–4, pp. 7–18, 2007.

Cho, Y. and Rhee, S., “Primary Circuit Dynamic Resistance Monitoring and Its Application to Quality Estimation during Resistance Spot Welding,” Welding Journal, Vol. 81, No. 6, pp. 104s–111s, 2002.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, D., Yu, J. & Rhee, S. Effect of a conically shaped hollow electrode on advanced high strength steel in three-sheet resistance spot welding. Int. J. Precis. Eng. Manuf. 17, 331–336 (2016). https://doi.org/10.1007/s12541-016-0041-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0041-9