Abstract

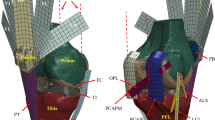

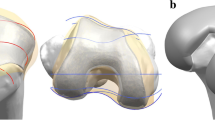

Joint kinematics and contact mechanics dictate the success of current total knee replacement (TKR) devices. Computational contact prediction is a feasible way of evaluating new TKR designs prior to physical testing and implementation. Previous finite element (FE) knee models have generally been used to predict stresses on contact areas and/or areas subjected to static or quasi-static loading. Explicit dynamic FE analyses have recently been used to effectively predict TKR kinematics and contact mechanics during dynamic loading conditions. In this study, we compared the functional load transmission and kinematic performance of two posterior-stabilized designs, standard and post-cam TKR versions, over a standardized loading cycle using three-dimensional contact finite element analysis. Our objective was to develop and experimentally validate an explicit FE TKR model that incorporates femoral-bearing articulations. Finite element-based computational contact pressure predictions were applied to gait cycles using both force-controlled and displacement-controlled inputs. A standard prosthesis showed a reduction in contact pressure compared with post-cam prosthesis components, as it redistributed the knee motion to two articulating interfaces with more linear motions at each interface. In this FE analysis, the wear of TKR bearings was dependent on kinematics at the articulating surfaces and on prosthesis design.

Similar content being viewed by others

References

Won, C.-H., Rohatgi, S., Kraay, M. J., Goldberg, V. M., and Rimnac, C. M., “Effect of Resin Type and Manufacturing Method on Wear of Polyethylene Tibial Components,” Clinical Orthopaedics and Related Research, Vol. 376, pp. 161–171, 2000.

Reeves, E. A., Barton, D. C., FitzPatrick, D. P., and Fisher, J., “Comparison of gas plasma and gamma irradiation in air sterilization on the delamination wear of the ultra-high molecular weight polyethylene used in knee replacements,” Proc. IME. H. J. Eng. Med., Vol. 214, pp. 249–255, 2000.

Kim, Y. K. and Minh, H. L., “Laboratory-level Surgical Robot System for Minimal Invasive Surgery (MIS) Total Knee Arthroplasty,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 2, pp. 237–242, 2011.

Sathasivam, S., Walker, P. S., Campbell, P. A., and Rayner, K., “The effect of contact area on wear in relation to fixed bearing and mobile bearing knee replacements,” J. Biomed. Mater. Res. Appl. Biomater., Vol. 58, pp. 282–290, 2001.

Lee, Y. S., Park, S. J., Song, E. K., Kim, J. S., and Kim, Y. H., “In Vivo Kinematics of a Cruciate Retaining Mobile-bearing Total Knee Arthroplasty,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 2, pp. 361–366, 2011.

Hood, R. W, Wright, T. M., and Burstein, A. H., “Retrieval analysis of total knee prostheses: a method and its application to 48 total condylar prostheses,” J. Biomed. Mater. Res., Vol. 17, No. 5, pp. 829–842, 1983.

Paling, I. H., Schmalzried, T. P., and Callaghan, J. J., “Wear in total hip and knee replacements,” J. Bone Jt. Surg. Am., Vol. 81, No. 1, pp. 115–36, 1999.

Bartel, D. L., Bicknell, V. L., and Wright, T. M., “The effect of conformity, thickness, and material on stresses in ultra-high molecular weight components for total joint replacement,” J. Bone Jt. Surg. Am., Vol. 68, No. 7, pp. 1041–1051, 1986.

Bartel, D. L., Rawlinson, J. J., Burstein, A. H., Ranawat, C. S., and Flynn, W. F. J., “Stresses in polyethylene components of contemporary total knee replacements,” Clin. Orthop., Vol. 317, pp. 76–82, 1995.

Kurtza, S. M., Pruittb, L, Jewettc, C. W., Crawfordc, R. P., Craneb, D. J., and Edidind, A. A., “The yielding, plastic flow, and fracture behavior of ultra-high molecular weight polyethylene used in total joint replacements,” Biomater., Vol. 19, pp. 1989–2003, 1998.

Estupiñán, J. A., Bartel, D. L., and Wright, T. M., “Residual stresses in ultra-high molecular weight polyethylene loaded cyclically by a rigid moving indenter in nonconforming geometries,” J. Orthop. Res., Vol. 16, No. 1, pp. 80–88, 1998.

Sathasivam, S. and Walker, P. S., “Computer model to predict subsurface damage in tibial inserts of total knees,” J. Orthop. Res., Vol. 16, No. 5, pp. 564–571, 1998.

Kurtz, S. M., Bartel, D. L., and Rimnac, C. M., “Post-irradiation aging affects the stresses and strains in UHMWPE components for total joint replacement,” Clin. Orthop., Vol. 350, pp. 209–220, 1998.

Godesta, A. C., Beaugoninb, M., Haugb, E., Taylora, M., and Gregsona, P. J., “Simulation of a knee joint replacement during gait cycle using explicit finite element analysis,” J. Biomech., Vol. 35, pp. 267–275, 2002.

Otto, J. K., Callaghan, J. J., and Brown, T. D., “Gait Cycle Finite Element Comparison of Rotating-Platform Total Knee Designs,” Clin. Orthop. Relat. Res., No. 410, pp. 181–188, 2003.

Material Property Data, http://matweb.com

Halloran, J. P., Easley, S. K., Petrella, A. J., and Rullkoetter, P. J., “Comparison of deformable and elastic foundation finite element simulations for predicting knee replacement mechanics,” J. Biomech. Eng., Vol. 127, pp. 813–818, 2005.

Hallorana, J. P., Petrellab, A. J., and Rullkoettera, P. J., “Explicit finite element modeling of TKR mechanics,” J. Biomech., Vol. 38, pp. 323–331, 2005.

Knighta, L. A., Pala, S., Colemanc, J. C., Bronsona, F., Haiderd, H., Levinec, D. L., Taylorb, M., and Rullkoettera, P. J., “Comparison of long-term numerical and experimental total knee replacement wear during simulated gait loading,” J. Biomech., Vol. 40, pp. 1550–1558, 2007.

Walker, P. S., Blunn, G. W., Broome, D. R., Perry, J., Watkins, A., Sathasivam, S., Dewar, M. E., and Paul, J. P., “A knee simulating machine for performance evaluation of total knee replacements,” J. Biomech., Vol. 30, pp. 83–89, 1997.

Pandit, H., Ward, T., Hollinghurst, D., Beard, D. J., Gill, H. S., Thomas, N. P., and Murray, D. W., “Influence of surface geometry and the cam-post mechanism on the kinematics of total knee replacement,” J. Bone Joint. Surg. [Br], Vol. 87-B, pp. 940–945, 2005.

Schai, P. A., Thornhill, T. S., and Scott, R. D., “Total knee arthroplasty with the PFC system: results at a minimum of ten years and survivorship analysis,” J. Bone Joint. Surg. [Br], Vol. 80-B, pp. 850–858, 1998.

Rodriguez, J. A., Bhende, H., and Ranawat, C. S., “Total condylar knee replacement: a 20-year followup study,” Clin. Orthop., Vol. 388, pp. 10–17, 2001.

Puloski, S. K. T., McCalden, R. W., MacDonald, S. J., Rorabeck, C. H., and Bourne, R. B., “Tibial post wear in posterior stabilized total knee arthroplasty: an unrecognized source of polyethylene debris,” J. Bone. Joint. Surg. [Am], Vol. 83-A, pp. 390–397, 2001.

Mestha, P., Shenava, Y., and D’Arcy, J. C., “Fracture of the polyethylene tibial post in posterior stabilized (Insall Burstein II) total knee arthroplasty,” J. Arthroplasty, Vol. 15, pp. 814–815, 2000.

Callaghan, J. J., O’Rourke, M. R., Goetz, D. D., Schmalzried, T. P., Campbell, P. A., and Johnston, R. C., “Tibial post impingement in posterior-stabilized total knee arthroplasty,” Clin. Orthop., Vol. 404, pp. 83–88, 2002.

Nakayama, K., Matsuda, S., Miura, H., Higaki, H., Otsuka, K., and Iwamoto, Y., “Contact stress at the post-cam mechanism in posterior-stabilised total knee arthroplasty,” J. Bone Joint Surg. [Br], Vol. 87-B, pp. 483–488, 2005.

Kurtza, S. M., Jewetta, C. W., Bergströma, J. S., Fouldsa, J. R., and Edidinb, A. A., “Miniature specimen shear punch test for UHMWPE used in total joint replacements,” Biomater., Vol. 23, pp. 1907–1919, 2002.

Lanovaz, J. L. and Ellis, R. E., “Dynamic simulation of a displacement-controlled total knee replacement wear tester,” Proc. IME. H. J. Eng. Med., Vol. 222, pp. 669–681, 2008.

Author information

Authors and Affiliations

Corresponding author

Additional information

Kyoung-Tak Kang and Joon-Hee Park contributed equally to this work

Rights and permissions

About this article

Cite this article

Kang, KT., Park, JH., Lee, KI. et al. Gait cycle comparions of cruciate sacrifice for total knee design.-explicit finite element. Int. J. Precis. Eng. Manuf. 13, 2043–2049 (2012). https://doi.org/10.1007/s12541-012-0269-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0269-y