Abstract

In the present article, the influence of the heat treatment on high-cycle fatigue and fracture behaviors of piston aluminum–silicon alloys was studied. For this objective, standard samples were tested under fully-reversed cyclic bending by a rotary fatigue machine and then, fracture behaviors were investigated by the field emission scanning electron microscopy. Before experiments, two heat treatments were performed on as-cast aluminum specimens, including a cooling process on samples after casting and the T6 treatment (solutioning for 5 h at 500 °C, quenching and ageing for 9 h at 180 °C). Obtained results showed that the heat treatment changed the distribution and the size and of silicon phases in the aluminum matrix and increased the hardness, significantly. In addition, the high-cycle fatigue lifetime increased by the heat treatment, surprisingly as 2146% and 411%, at the highest stress level and the lowest stress level, respectively. This enhancement was more than the improvement by cooling samples after casting. Observing cleavage and quasi-cleavage marks on the specimen fracture surfaces was the reason for the brittle fracture behavior. Besides, cleavage planes were smaller in heat treated samples, with shorter micro-cracks or lower crack densities, which affected the fatigue lifetime of the material.

Graphic Abstract

Similar content being viewed by others

References

M. Azadi, Effects of strain rate and mean strain on cyclic behavior of aluminum alloys under isothermal and thermo-mechanical fatigue loadings. Int. J. Fatigue 47, 148–153 (2013)

M. Azadi, G.H. Farrahi, G. Winter, W. Eichlseder, The effect of various parameters on out-of-phase thermo-mechanical fatigue lifetime of A356.0 cast aluminum alloy. Int. J. Eng. Trans. C Asp. 26(12), 1459–1468 (2013)

M. Azadi, G. Winter, G.H. Farrahi, W. Eichlseder, Comparison between isothermal and non-isothermal fatigue behaviors in cast aluminum–silicon–magnesium alloy. Strength Mater. 47(6), 840–848 (2015)

F.S. Silva, Fatigue on engine pistons—a compendium of case studies. Eng. Fail. Anal. 13, 480–492 (2006)

M.J. Caton, J.W. Jones, J.E. Allison, The influence of heat treatment and solidification time on the behavior of small-fatigue-cracks in a cast aluminum alloy. Mater. Sci. Eng. A 314, 81–85 (2001)

J.M. Boileau, J.E. Allison, The effect of solidification time and heat treatment on the fatigue properties of a cast 319 aluminum alloy. Metall. Mater. Trans. A 34, 1807–1820 (2003)

R. Sadeler, Y. Totik, M. Gavgali, I. Kaymaz, Improvements of fatigue behavior in 2014 Al alloy by solution heat treating and age-hardening. Mater. Des. 25, 439–445 (2004)

M.N. Desmukha, R.K. Pandey, A. Mukhopadhyay, Effect of aging treatments on the kinetics of fatigue crack growth in 7010 aluminum alloy. Mater. Sci. Eng. A 435–436, 318–326 (2006)

V. Firouzdor, M. Rajabi, E. Nejati, F. Khomamizadeh, Effect of microstructural constituents on the thermal fatigue life of A319 aluminum alloy. Mater. Sci. Eng. A 454–455, 528–535 (2007)

R.A. Siddiqui, S.A. Abdul-Wahab, T. Pervez, Effect of aging time and aging temperature on fatigue and fracture behavior of 6063 aluminum alloy under seawater influence. Mater. Des. 29, 70–79 (2008)

M. Hornqvist, B. Karlsson, Influence of heat treatment on the cyclic deformation properties of aluminum alloy AA7030. Mater. Sci. Eng. A 479, 345–355 (2008)

T. Takahashia, K. Sasakib, Low cycle thermal fatigue of aluminum alloy cylinder head in consideration of changing metrology microstructure. Proc. Eng. 2, 767–776 (2010)

A. May, M.A. Belouchrani, S. Taharboucht, A. Boudras, Influence of heat treatment on the fatigue behavior of two aluminum alloys 2024 and 2024 plated. Proc. Eng. 2, 1795–1804 (2010)

M. Azadi, M.M. Shirazabad, Heat treatment effect on thermo-mechanical fatigue and low cycle fatigue behaviors of A356.0 aluminum alloy. Mater. Des. 45, 279–285 (2013)

S.K. Shaha, F. Czerwinski, W. Kasprzak, J. Friedman, D.L. Chen, Effect of Mn and heat treatment on improvements in static strength and low-cycle fatigue life of an Al–Si–Cu–Mg alloy. Mater. Sci. Eng. A 657, 441–452 (2016)

M. Wang, J.C. Pang, S.X. Li, Z.F. Zhang, Low-cycle fatigue properties and life prediction of Al–Si piston alloy at elevated temperature. Mater. Sci. Eng. A 704, 480–492 (2017)

S. Khisheh, K. Khalili, M. Azadi, V. Zaker Hendoabadi, Heat treatment effect on microstructure, mechanical properties and fracture behavior of cylinder head aluminum–silicon–copper alloy. J. Engine Res. 50, 55–65 (2018)

C. Zhang, H. Zhu, H. Liao, Y. Cheng, Z. Hu, X. Zeng, Effect of heat treatments on fatigue property of selective laser melting AlSi10Mg. Int. J. Fatigue 116, 513–522 (2018)

T. Haskel, G.O. Verran, R. Barbieri, Rotating and bending fatigue behavior of A356 aluminum alloy: effects of strontium addition and T6 heat treatment. Int. J. Fatigue 114, 1–10 (2018)

M. Azadi, S. Rezanezhad, M. Zolfaghari, M. Azadi, Effects of various ageing heat treatments on microstructural features and hardness of piston aluminum alloy. Int. J. Eng. Trans. A 32(1), 92–98 (2019)

Mahle Company, Pistons and Engine Testing (Springer, Berlin, 2016)

M. Zeren, The effect of heat-treatment on aluminum-based piston alloys. Mater. Des. 28, 2511–2517 (2007)

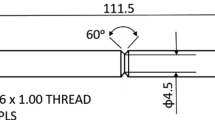

Metallic materials—rotating bar bending fatigue testing, Standard No. ISO-1143, ISO International Standard (2010)

M.J. Khameneh, M. Azadi, Evaluation of high-cycle bending fatigue and fracture behaviors in EN-GJS700-2 ductile cast iron of crankshafts. Eng. Fail. Anal. 85, 189–200 (2018)

T.O. Mbuy, I. Sinclair, A.J. Moffat, P.A.S. Reed, Micro-mechanisms of fatigue crack growth in cast aluminum piston alloys. Int. J. Fatigue 42, 227–237 (2012)

M. Azadi, M. Zolfaghari, S. Rezanezhad, M. Azadi, Effects of SiO2 nano-particles on tribological and mechanical properties of aluminum matrix composites by different dispersion methods. Appl. Phys. A 124(5), 377 (2018)

M. Zeren, E. Karakulak, S. Gumus, Influence of Cu addition on microstructure and hardness of near-eutectic Al–Si–xCu-alloys. Trans. Nonferr. Met. Soc. China 21(8), 1698–1702 (2011)

M. Zhu, Z. Jian, G. Yang, Y. Zhou, Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloy. Mater. Des. 36, 243–249 (2012)

L.Y. Pio, Effect of T6 heat treatment on the mechanical properties of gravity die cast A356 aluminum alloy. J. Appl. Sci. 11(11), 2048–2052 (2011)

E. Ogris, A. Wahlen, H. Luechinger, P.J. Uggowitzer, On the silicon sheroidization in Al–Si alloys. J. Light Met. 2, 263–269 (2002)

D.L. Zhang, L.H. Zheng, D.H. StJohn, Effect of a short solution treatment time on microstructure and mechanical properties of modified Al–7wt.%Si–0.3wt.%Mg alloy. J. Light Met. 2, 27–36 (2002)

G. Zhang, J. Zhang, B. Li, W. Cai, Double-stage hardening behavior and fracture characteristics of a heavily alloyed Al–Si piston alloy during low-cycle fatigue loading. Mater. Sci. Eng. A 561, 26–33 (2013)

ASM Handbook, Properties and Selection: Nonferrous Alloy and Special Purposed Materials, vol. 2 (ASM International, Almere, 1992)

J. Liu, Q. Zhang, Z. Zue, Y. Xiong, F. Ren, A. Volinsky, Microstructure evolution of Al–12Si–CuNiMg alloy under high temperature low cycle fatigue. Mater. Sci. Eng. A 574, 186–190 (2013)

A.J. Moffat, S. Barnes, B.G. Mellor, P.A.S. Reed, The effect of silicon content on long crack fatigue behavior of aluminum–silicon piston alloys at elevated temperature. Int. J. Fatigue 27(10–11), 1564–1570 (2005)

E. Rincon, H.F. Lopez, M.M. Cisneros, H. Mancha, M.A. Cisneros, Effect of temperature on the tensile properties of an as-cast aluminum alloy A319. Mater. Sci. Eng. A 452–453, 682–687 (2007)

Acknowledgements

Authors would tend to thank Motorsazi Pooya Neyestanak (MPN) Company, in Isfahan, Iran for their financial supports, in addition to provide raw materials and to perform the casting process.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rezanezhad, S., Azadi, M. & Azadi, M. Influence of Heat Treatment on High-Cycle Fatigue and Fracture Behaviors of Piston Aluminum Alloy Under Fully-Reversed Cyclic Bending. Met. Mater. Int. 27, 860–870 (2021). https://doi.org/10.1007/s12540-019-00498-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00498-7