Abstract

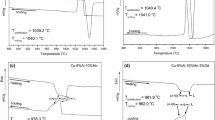

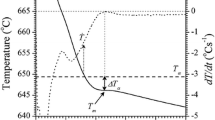

The residual stresses with different heat treatment conditions have been measured and correlated with the microstructural behavior of AA365. 30 and 100 K/min cooling of AA365 inhibited the transformation of precipitates under 773 K, respectively. The alloy cooled at 30 and 100 K/min exhibited tensile residual stresses of 6.2 and 5.4 MPa, respectively, while the alloy cooled at 1 and 10 K/min showed compressive stresses of − 12.8 and − 10.3 MPa, respectively. The formation β′, β″, and other intermetallic compounds affected the compressive residual stresses, and that the fracture of the brittle intermetallic phases could reduce the extent of residual stresses in the lattice through plastic deformation.

Similar content being viewed by others

References

T. Siyi, L. Lin, Res. Dev. 5, 186–189 (2008)

Report of Sub-committee T.S.32, Internal Stress in Castingsitle. Proc. Inst. Brit. Found., pp. A179–A189 (1952)

R.N. Parkins, A. Cowan, Proc. Inst. Brit. Found., pp. A99–A109 (1953)

Primary aluminum: Alloys for Pressure Die Casting, Rheinfelden alloys, version 3, pp. 30. www.rheinfelden-alloys.eu. Accessed Dec 2015

J.E. Gruzleski, B.M. Closset, The Treatment of Liquid Aluminum–Silicon Alloys (American Foundry Society, Des Plaines, 1990), pp. 14–15

E. Samuel, A.M. Samuel, H.W. Doty, S. Valtierra, F.H. Samuel, Int. J. Cast Met. Res. 27, 107–114 (2014)

A. Serizawa, T. Sato, M.K. Miller, Mater. Sci. Eng. A 561, 492–497 (2013)

M.A. van Huis, J.H. Chen, M.H.F. Sluiter, H.W. Zandbergen, Acta Mater. 55, 2183–2199 (2007)

M. Vlach, J. Čížek, B. Smola, O. Melikhova, M. Vlček, V. Kodetová, H. Kudrnová, P. Hruška, Mater. Charact. 129, 1–8 (2017)

D.S. MacKenzie, V. Forge, Heat Treat. Prog. 5, 37–43 (2005)

E. Lee, W. Khalfaoui, B. Mishra, B. Palmer, J. Test. Eval. 45, 1–8 (2017)

S.D.A.P.N. Crepeau, J.A. Warden, AFS Trans. 98, 813–822 (1990)

N. Chobaut, D. Carron, S. Arsène, P. Schloth, J.M. Drezet, J. Mater. Process. Technol. 222, 373–380 (2015)

S. Esmaeili, X. Wang, D.J. Lloyd, W.J. Poole, Metall. Mater. Trans. A 34, 751–763 (2003)

V. Fallah, A. Korinek, N. Ofori-Opoku, B. Raeisinia, M. Gallerneault, N. Provatas, S. Esmaeili, Acta Mater. 82, 457–467 (2015)

S. Shabestari, Mater. Sci. Eng. A 383, 289–298 (2004)

P. Crepeau, Trans. Am. Foundrymen’s Soc. 103, 361–366 (1995)

A. Mohamed, A. Samuel, F. Samuel, H. Doty, Mater. Des. 30, 3943–3957 (2009)

A. Mohamed, F. Samuel, A. Samuel, H. Doty, Mater. Des. 30, 4218–4229 (2009)

S. Ferraro, A. Bjurenstedt, S. Seifeddine, Metall. Mater. Trans. A 46, 3713–3722 (2015)

V. Rivlin, G. Raynor, Int. Met. Rev. 26, 133–152 (1981)

C.-L. Chen, A. Richter, R. Thomson, Intermetallics 18, 499–508 (2010)

Acknowledgements

This work was made possible by Advanced Casting Research Center (ACRC) in Metal Processing Institute “Measurement and Modeling of Residual Stress in Aluminum Casting”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, E., Walde, C. & Mishra, B. Effects of Cooling Rate on Precipitate Evolution and Residual Stresses in Al–Si–Mn–Mg Casting Alloy. Met. Mater. Int. 24, 815–820 (2018). https://doi.org/10.1007/s12540-018-0094-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0094-7