Abstract

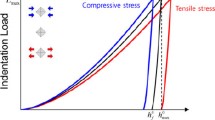

In instrumented indentation testing (IIT), residual stress can be evaluated by shift in indentation load-depth curves for stress-free and stressed states. Although the average surface residual stress is able to be evaluated with Vickers indenter, in order to know stress directionality, another indentation tests with two-fold symmetric indenter, for example, Knoop indenter, are needed. As some necessities for evaluating nonequibiaxial residual stress within small indent area, we suggest a novel way to evaluate directionality of residual stress, p, using wedge indenter characterized by two parameters, edge length and inclined angle. We develop wedge-indentation-mechanics model based on predetermined conversion factors which are determined by IITs for various uniaxial stressed states combining with finite element analysis simulations. By utilizing the developed model, directionality of residual stress is evaluated through two serial wedge IITs with respect to principal directions. We find good agreements between applied residual stress and residual stress evaluated by the developed model for biaxial tensile stress states.

Similar content being viewed by others

References

I. C. Noyan and J. B. Cohen, Residual Stress, pp. 13–46, Springer-Verlag, New York, USA (1987).

G. Totten, M. Howes, and T. Inoue, Handbook of Residual Stress and Deformation of Steel, pp. 27–53, ASM International, Ohio, USA (1996).

Y.-H. Lee, S. Ahn, J.-Y. Kim, C.-P. Park, and H.-K. Jang, Korean J. Met. Mater. 53, 162 (2015).

Y.-H. Lee, J. S. Park, Y. Kim, and Y.-H. Huh, Korean J. Met. Mater. 53, 90 (2015).

T. Y. Tsui, W. C. Oliver, and G. M. Pharr, J. Mater. Res. 11, 752 (1996).

A. Bolshakov, W. C. Oliver, and G. M. Pharr, J. Mater. Res. 11, 760 (1996).

S. Suresh and A. E. Giannakopoulos, Acta Mater. 46, 5755 (1998).

J. G. Swadener, B. Taljat, and G. M. Pharr, J. Mater. Res. 16, 2091 (2001).

A. E. Giannakopoulos, J. Appl. Mech. 70, 638 (2003).

Y.-H. Lee and D. Kwon, Scripta Mater. 49, 459 (2003).

J.-I. Jang, J. Ceram. Process. Res. 10, 291 (2009).

Y.-H. Lee and D. Kwon, Acta Mater. 52, 1555 (2004).

Y.-H. Lee, K. Takashima, Y. Higo, and D. Kwon, Scripta Mater. 49, 459 (2003).

J.-H. Han, J.-S. Lee, Y.-H. Lee, M.-J. Choi, G. Lee, D. Kwon, et al. Key Eng. Mat. 345-346, 1125 (2007).

M.-J. Choi, S.-K. Kang, I. Kang, and D. Kwon, J. Mater. Res. 27, 1 (2011).

Y.-C. Kim, M.-J. Choi, D. Kwon, and J.-Y. Kim, Met. Mater. Int. 21, 850 (2015).

Y.-C. Kim, H.-J. Ahn, D. Kwon, and J.-Y. Kim, Met. Mater. Int. 22, 12 (2016).

T. Y. Tsui, W. C. Oliver, and G. M. Pharr, J. Mater. Res. 11, 752 (1996).

A. Bolshakov, W. C. Oliver, and G. M. Pharr, J. Mater. Res. 11, 760 (1996).

S. Suresh and A. E. Giannakopoulos, Acta Mater. 46, 5755 (1998).

J. G. Swadener, B. Taljat, and G. M. Pharr, J. Mater. Res. 16, 2091 (2001).

A. E. Giannakopoulos, J. Appl. Mech. 70, 638 (2003).

Y.-H. Lee and D. Kwon, Scripta Mater. 49, 459 (2003).

J.-I. Jang, J. Ceram. Process. Res. 10, 291 (2009).

Y.-H. Lee and D. Kwon, Acta Mater. 52, 1555 (2004).

Y.-H. Lee, K. Takashima, Y. Higo, and D. Kwon, Scripta Mater. 49, 459 (2003).

J.-H. Han, J.-S. Lee, Y.-H. Lee, M.-J. Choi, G. Lee, D. Kwon, et al. Key Eng. Mat. 345-346, 1125 (2007).

M.-J. Choi, S.-K. Kang, I. Kang, and D. Kwon, J. Mater. Res. 27, 1 (2011).

Y.-C. Kim, M.-J. Choi, D. Kwon, and J.-Y. Kim, Met. Mater. Int. 21, 850 (2015).

Y.-C. Kim, H.-J. Ahn, D. Kwon, and J.-Y. Kim, Met. Mater. Int. 22, 12 (2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahn, HJ., Kim, Jh., Xu, H. et al. Directionality of residual stress evaluated by instrumented indentation testing using wedge indenter. Met. Mater. Int. 23, 465–472 (2017). https://doi.org/10.1007/s12540-017-6573-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6573-4