Abstract

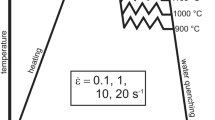

Microstructure and texture development in an austenitic stainless steel at high temperatures and low strain rate were studied through laboratory scale compression and rolling experiments. The uniaxial compression tests were performed under constant temperature with sample temperatures of 900 °C, 1000 °C and 1100 °C whereas, the rolling experiments were performed at the same initial sample temperatures but in a transient condition. The average strain rate was 1 s−1 and 1.23 s−1, during the compression and rolling experiments, respectively. After deformation the microstructure and texture developed in the samples were examined through the electron back scattered diffraction technique. For compression test, deformation at 900 °C produces mostly deformed grains whereas, at 1000 °C and 1100 °C only recrystallized grains were observed. In contrast, rolling produces partially recrystallized microstructures at all the three temperatures. Finite element (FE) modeling was used to calculate the variation of the state variables like temperature, strain and strain rate and the differences in microstructure for the two processes were analyzed in the light of FE simulation results. In texture, tube orientation like α fiber was developed by the compression at 900 °C whereas, at 1000 °C and 1100 °C random texture with cube as the significant texture component, was observed. Similarly in rolling, α, β and τ fibers with different intensities were developed at the center and random texture was observed near the surface of the samples.

Similar content being viewed by others

References

Chen WC, Samarasekera IV, Hawbolt EB (1993) Fundamental phenomena governing heat transfer during rolling. Metall Trans A 24A 24(6):1307–1320. https://doi.org/10.1007/BF02668199

Devadas C, Samarasekera IV, Hawbolt EB (1991) The thermal and metallurgical state of steel strip during hot rolling: part I. characterization of heat transfer. Metall Trans A 22(2):307–319. https://doi.org/10.1007/BF02656800

Aiyedun PO, Sparling LGM, Sellars CM (1997) Temperature changes in hot flat rolling of steels at low strain rates and low reduction. Proc Inst Mech Eng B J Eng Manuf 211(4):261–284. https://doi.org/10.1243/0954405971516257

Devadas C, Samarasekera IV, Hawbolt EB (1991) The thermal and metallurgical state of steel strip during hot rolling: part III. Microstructural evolution. Metall Trans A 22(2):335–349. https://doi.org/10.1007/BF02656800

Han SH, Choi SH, Choi JK, Seong HG, Kim IB (2010) Effect of hot-rolling processing on texture and r-value of annealed dual-phase steels. Mater Sci Eng A 527(7-8):1686–1694. https://doi.org/10.1016/j.msea.2009.11.016

Serajzadeh S, Karimi Taheri A, Nejati M, Izadi J, Fattahi M (2002) An investigation on strain inhomogeneity in hot strip rolling process. J Mater Process Technol 128(1-3):88–99. https://doi.org/10.1016/S0924-0136(02)00276-5

Shahani AR, Setayeshi S, Nodamaie SA, Asadi MA, Rezaie S (2009) Prediction of influence parameters on the hot rolling process using finite element method and neural network. J Mater Process Technol 209(4):1920–1935. https://doi.org/10.1016/j.jmatprotec.2008.04.055

Frommert M, Gottstein G (2009) Mechanical behavior and microstructure evolution during steady-state dynamic recrystallization in the austenitic steel 800H. Mater Sci Eng A 506(1-2):101–110. https://doi.org/10.1016/j.msea.2008.11.035

Fang X, Zhang K, Guo H, Wang W, Zhou B (2008) Twin-induced grain boundary engineering in 304 stainless steel. Mater Sci Eng A 487(1-2):7–13. https://doi.org/10.1016/j.msea.2007.09.075

Chowdhury SG, Das S, De PK (2005) Cold rolling behaviour and textural evolution in AISI 316L austenitic stainless steel. Acta Mater 53(14):3951–3959. https://doi.org/10.1016/j.actamat.2005.05.006

Mirzadeh H, Parsa MH, Ohadi D (2013) Hot deformation behavior of austenitic stainless steel for a wide range of initial grain size. Mater Sci Eng A 569:54–60. https://doi.org/10.1016/j.msea.2013.01.050

Mirzadeh H, Cabrera JM, Najafizadeh A, Calvillo PR (2012) EBSD study of a hot deformed austenitic stainless steel. Mater Sci Eng A 538:236–245. https://doi.org/10.1016/j.msea.2012.01.037

Dehghan-Manshadi A, Barnett MR, Hodgson PD (2008) Hot deformation and recrystallization of austenitic stainless steel: part I. dynamic recrystallization. Metall Mater Trans A 39(6):1359–1370. https://doi.org/10.1007/s11661-008-9513-6

Wahabi M, Gavard L, Cabrera JM et al (2005) EBSD study of purity effects during hot working in austenitic stainless steels. Mater Sci Eng A 393(1-2):83–90. https://doi.org/10.1016/j.msea.2004.09.064

Belyakov A, Miura H, Sakai T (2000) Dynamic recrystallization in ultra fine-grained 304 stainless steel. Scr Mater 43(1):21–26. https://doi.org/10.1016/S1359-6462(00)00373-0

Belyakov A, Miura H, Sakai T (1998) Dynamic recrystallization under warm deformation of a 304 type austenitic stainless steel. Mater Sci Eng A 255(1-2):139–147. https://doi.org/10.1016/S0921-5093(98)00784-9

Wahabi M, Cabrera JM, Prado JM (2003) Hot working of two AISI 304 steels: a comparative study. Mater Sci Eng A 343(1-2):116–125. https://doi.org/10.1016/S0921-5093(02)00357-X

Sun H, Sun Y, Zhang R, Wang M, Tang R, Zhou Z (2014) Hot deformation behavior and microstructural evolution of a modified 310 austenitic steel. Mater Des 64:374–380. https://doi.org/10.1016/j.matdes.2014.08.001

Han Y, Shi J, Xu L, Cao WQ, Dong H (2012) Effect of hot rolling temperature on grain size and precipitation hardening in a Ti-microalloyed low-carbon martensitic steel. Mater Sci Eng A 553:192–199. https://doi.org/10.1016/j.msea.2012.06.015

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena, 2nd edn. Elsevier Ltd, Oxford

Dehghan-Manshadi A, Barnett MR, Hodgson PD (2008) Recrystallization in AISI 304 austenitic stainless steel during and after hot deformation. Mater Sci Eng A 485(1-2):664–672. https://doi.org/10.1016/j.msea.2007.08.026

Sakai T, Belyakov A, Kaibyshev R, Miura H, Jonas JJ (2014) Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog Mater Sci 60:130–207. https://doi.org/10.1016/j.pmatsci.2013.09.002

Yanushkevich Z, Belyakov A, Kaibyshev R (2015) Microstructural evolution of a 304-type austenitic stainless steel during rolling at temperatures of 773-1273 K. Acta Mater 82:244–254. https://doi.org/10.1016/j.actamat.2014.09.023

Taylor AS, Hodgson PD (2011) Dynamic behaviour of 304 stainless steel during high Z deformation. Mater Sci Eng A 528(9):3310–3320. https://doi.org/10.1016/j.msea.2010.12.093

Kim S-I, Yoo Y-C (2001) Dynamic recrystallization behavior of AISI 304 stainless steel. Mater Sci Eng A 311(1-2):108–113. https://doi.org/10.1016/S0921-5093(01)00917-0

Dehghan-Manshadi A, Barnett MR, Hodgson PD (2008) Hot deformation and recrystallization of austenitic stainless steel: part II. Post-deformation recrystallization. Metall Mater Trans A 39(6):1371–1381. https://doi.org/10.1007/s11661-008-9513-6

Sakai BT, Saito Y, Kato K (1987) Recrystallization and texture formation in high speed hot rolling of austenitic stainless steel. Trans Iron Steel Inst Jpn 27(6):520–525

Raabe D (1995) Inhomogeneity of the crystallographic texture in a hot-rolled austenitic stainless steel. J Mater Sci 30(1):47–52

Prasad YVRK, Rao KP, Sasidhar S (2015) Hot working guide a compendium of processing map, second Edi. ASM International, Ohio

Rout M, Pal SK, Singh SB (2016) Finite element simulation of a cross rolling process. J Manuf Process 24:283–292. https://doi.org/10.1016/j.jmapro.2016.09.012

Kobayashi S, Oh S-I, Altan T (1989) Metal forming and the finite element method. Oxford University Press, New York

Mandal S, Bhaduri AK, Subramanya Sarma V (2011) A study on microstructural evolution and dynamic recrystallization during isothermal deformation of a Ti-modified austenitic stainless steel. Metall Mater Trans A Phys Metall Mater Sci 42(4):1062–1072. https://doi.org/10.1007/s11661-010-0517-7

Wang SR, Tseng AA (1995) Macro- and micro-modelling of hot rolling of steel coupled by a micro-constitutive relationship. Mater Des 16(6):315–336. https://doi.org/10.1016/0261-3069(96)00005-2

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rout, M., Singh, S.B. & Pal, S.K. Microstructure and texture evolution in austenitic stainless steel during low strain rate deformation at elevated temperature. Int J Mater Form 13, 605–621 (2020). https://doi.org/10.1007/s12289-019-01500-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-019-01500-8