Abstract

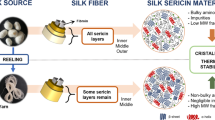

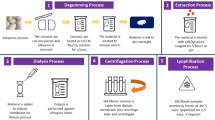

Silk sericin has been studied for application in the biomedical and cosmetic fields, given its good water retention and wound-healing properties. Although sericin can be obtained by extraction in hot water, this leads to molecular degradation. Recently, it was reported that raw silk can be used as a binder to prepare non-woven silk fabrics using character of sericin. Therefore, a better understanding of the characteristics of raw sericin is required for more effective utilization. In the present study, the effect of silkworm variety on the characteristics of raw sericin was examined. The amounts of sericin and non-protein materials were found to differ depending on the silkworm variety. The crystallinity indexes of the silk resulting from degumming and heat treatment varied slightly with the silkworm variety. The difference in the tensile strengths of silk yarns spun from raw and degummed silk filaments was found to be highly dependent on the silkworm variety, with the strength decreasing in the order N74 > Imbakgalwon > Baekokjam > Wonwon 126. The extent of increases in the tensile strength and elongation of the silk yarn after hot-press treatment was strongly influenced by the silkworm variety, given the amount of raw sericin differed with the silkworm variety. It is thought that the use of raw sericin from an appropriate silkworm variety will accelerate the development of sericin products in both the cosmetic and biomedical fields.

Similar content being viewed by others

References

M. J. Jang and I. C. Um, Eur. Polym. J., 93, 761 (2017).

M. N. Padamwar, A. P. Pawar, A. V. Daithankar, and K. R. Mahadik, J. Cosmet. Dermatol., 4, 250 (2005).

P. Aramwit, S. Kanokpanont, W. De-Eknamkul, and T. Srichana, J. Biosci. Bioeng., 107, 556 (2009).

N. Nagai, T. Murao, Y. Ito, N. Okamoto, and M. Sasaki, Biol. Pharm. Bull., 32, 933 (2009).

M. L. Gulrajani, K. P. Brahma, P. S. Kumar, and R. Purwar, J. Appl. Polym. Sci., 109, 314 (2008).

N. Suzuki, A. Fujimura, T. Nagai, I. Mizumoto, T. Itami, H. Hatate, T. Nozawa, N. Kato, T. Nomoto, and B. Yoda, Biofactors, 21, 329 (2004).

R. Dash, M. Mandal, S. K. Ghosh, and S. C. Kundu, Mol. Cell. Biochem., 311, 111 (2008).

X. Zhang, M. M. R. Khan, T. Yamamoto, M. Tsukada, and H. Morikawa, Int. J. Biol. Macromol., 50, 337 (2012).

R. Zhao, X. Li, B. Sun, Y. Zhang, D. Zhang, Z. Tang, X. Chen, and C. Wang, Int. J. Biol. Macromol. 68, 92 (2014).

H. Y. Kweon, J. H. Yeo, K. G. Lee, Y. W. Lee, Y. H. Park, J. H. Nahm, and C. S. Cho, Macromol. Rapid Commun., 21, 1302 (2000).

L. J. Zhu, M. Arai, and K. Hirabayashi, J. Seric. Sci. Jpn. 64, 415 (1995).

L. J. Zhu, M. Arai, and K. Hirabayashi, J. Seric. Sci. Jpn. 65, 270 (1996).

Y. N. Jo, B. D. Park, and I. C. Um, Int. J. Biol. Macromol., 81, 936 (2015).

A. Nishida, M. Yamada, T. Kanazawa, Y. Takashima, K. Ouchi, and H. Okada, Int. J. Pharm., 407, 44 (2011).

Y. N. Jo and I. C. Um, Int. J. Biol. Macromol., 78, 287 (2015).

H. Yun, M. K. Kim, H. W. Kwak, J. Y. Lee, M. H. Kim, and K. H. Lee, Int. J. Biol. Macromol., 82, 945 (2016).

H. Oh, J. Y. Lee, A. Kim, C. S. Ki, J. W. Kim, Y. H. Park, and K. H. Lee, Fiber. Polym., 8, 470 (2007).

Y. Q. Zhang, M. L. Tao, W. D. Shen, Y. Z. Zhou, Y. Ding, Y. Ma, and W. L. Zhou, Biomaterials, 25, 3751 (2004).

S. K. Das, T. Dey, and S. C. Kundu, RSC Adv., 4, 2137 (2014).

K. Y. Cho, J. Y. Moon, Y. W. Lee, K. G. Lee, J. H. Yeo, H. Y. Kweon, K. H. Kim, and C. S. Cho, Int. J. Biol. Macromol., 32, 36 (2003).

Y. Zhang, Biotechnol. Adv., 20, 91 (2002).

T. Siritientong, A. Angspatt, J. Ratanavaraporn, and P. Aramwit, Pharm. Res., 31, 104 (2014).

P. Aramwit, O. Keongamaroon, T. Siritientong, N. Bang, and O. Supasyndh, BMC Nephrol., 13, 119 (2012).

C. J. Park, J. Ryoo, C. S. Ki, J. W. Kim, I. S. Kim, and I. C. Um, Int. J. Biol. Macromol., 119, 821 (2018).

J. H. Lee, Y. S. Bae, S. J. Kim, D. W. Song, Y. H. Park, D. G. Bae, J. H. Choi, and I. C. Um, Int. J. Biol. Macromol., 106, 39 (2018).

D. E. Chung, H. H. Kim, M. K. Kim, K. H. Lee, Y. H. Park, and I. C. Um, Int. J. Biol. Macromol., 79, 943 (2015).

D. E. Chung, J. H. Lee, H. Kweon, K. G. Lee, and I. C. Um, Int. J. Indust. Entomol., 30, 81 (2015).

B. K. Park and I. C. Um, Fiber. Polym., 16, 1935 (2015).

M. J. Jang and I. C. Um, Int. J. Indust. Entomol., 30, 75 (2015).

J. H. Lee, D. W. Song, Y. H. Park, and I. C. Um, Int. J. Biol. Macromol., 89, 273 (2016).

I. C. Um, H. Y. Kweon, Y. H. Park, and S. Hudson, Int. J. Biol. Macromol., 29, 91 (2001).

H. J. Kim and I. C. Um, Int. J. Biol. Macromol., 67, 387 (2014).

J. S. Ko, C. S. Ki, and I. C. Um, Fiber. Polym., 19, 507 (2018).

B. K. Park and I. C. Um, Int. J. Biol. Macromol., 95, 8 (2017).

Y. N. Jo, B. D. Park, and I. C. Um, Int. J. Biol. Macromol., 81, 936 (2015).

H. J. Kim, M. K. Kim, K. H. Lee, S. K. Nho, M. S. Han, and I. C. Um, Int. J. Biol. Macromol., 104, 294 (2017).

M. L. Gulrajani, “Degumming of Silk” (M. L. Gulrajani Ed.), Silk Dyeing Printing and Finishing, pp.63-95. Department of Textile Technology Indian Institute of Technology, New Delhi, 1988.

C. Chung, M. Lee, and E. K. Choe, Carbohydr. Polym., 58, 417 (2004).

B. K. Park and I. C. Um, Int. J. Biol. Macromol., 106, 1166 (2018).

D. E. Chung and I. C. Um, Fiber. Polym., 15, 153 (2014).

M. M. R. Khan, M. Tsukada, Y. Gotoh, H. Morikawa, G. Freddi, and H. Shiozaki, Bioresour. Technol., 101, 8439 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, S.J., Um, I.C. Effect of Silkworm Variety on Characteristics of Raw Sericin in Silk. Fibers Polym 20, 271–279 (2019). https://doi.org/10.1007/s12221-019-8715-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-019-8715-4