Abstract

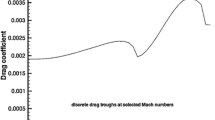

As the supporting supplier of the main engine plant, the general air filter manufacturers have insufficient technical reserves. The structural optimization of air filter is often based on the bench experiment, which has high implementation cost and poor performance. In view of this, taking computational fluid dynamics (CFD) as the basic technical means, an optimization design method based on parametric sensitivity combined with equidistant search was proposed. Specifically, the sensitivity of local structure parameters to pressure loss was analyzed by taking local structure of air filter as the object. According to the sensitivity, the method of equidistant search was used to optimize the parameters in order, so as to achieve the goal of overall optimization. After optimization, the pressure loss decreased by 45.13% and the effect was remarkable.

Similar content being viewed by others

References

Zhao S E, Jiang A L. A engine air filter of CFD optimization design [J]. Journal of Mechanical Design and Manufacturing, 2015, (8): 163–166(Ch).

Kang N, Cao Y. A car air filter structure modification based on CFD [J]. Journal of Automotive Technology, 2015, (4): 1–5(Ch).

Zeng P Y, Du A M, Du Y B, et al. Performance analysis and optimization of automotive air filter assembly [J]. Journal of Automotive Engine, 2012, (2): 41–45(Ch).

Li C Y, Wang W C, Ma Y. Structural performance optimization based on parameter sensitivity [J]. China Mechanical Engineering, 2011, 22(4): 397–402(Ch).

Chai G Y, Huang S, Yue W Z, et al. Optimization design of crankshaft torsional vibration damper based on sensitivity analysis [J]. Journal of Agricultural Engineering, 2009, 25(5): 105–108(Ch).

Yuan Z Q, Huang F J, Liu J W, et al. Car air filter inlet resistance analysis [J]. Journal of Huaqiao University (Natural Science Edition), 2016, 5(3): 268–272(Ch).

Meng M, Ye F Q, Zhou X. Structure analysis and optimization of automotive air filter [J]. Journal of Jiangsu University of Science and Technology (Natural Science Edition), 2016, 30(4): 344–348(Ch).

Guan Y J, Zhang L F, Li X, et al. Modal analysis and structure optimization of the car air filter [J]. Computer Simulation, 2015, 32(4): 124–128(Ch).

Ren A Y, Sun H O, Wang Z Y, et al. Multi-stage optimization method for air-intake system of hovercraft based on autonomous optimization [J]. Journal of the Chinese Institute of Engineers, 2017, (8): 1–10.

Al-Sarkhi A, Chambers F W. Optimization technique for design of automotive air filter housings with improved fluid dynamic performance and filtration [J]. Particulate Science and Technology, 2004, 22: 235–252.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Supported by the General Plan Projects of Science and Technology of Jiangxi Provincial Department of Education (GJJ151161, GJJ180976), the Plan Projects of Science and Technology of Jiangxi Provincial Department of Science and Technology (20161BBE50053), and the Foundation of the Center of Collaboration and Innovation (18XTKFYB03)

Rights and permissions

About this article

Cite this article

Xiang, F., Xiang, Z. & Cheng, W. Structure Optimization of Air Filter Based on Parametric Sensitivity. Wuhan Univ. J. Nat. Sci. 24, 271–276 (2019). https://doi.org/10.1007/s11859-019-1396-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11859-019-1396-4

Key words

- air filter

- parametric sensitivity

- computational fluid dynamics (CFD)

- equidistant search method

- structure optimization design