Abstract

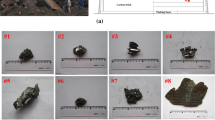

The abnormal erosion of hearth refractories is widely recognized as the main limiting factor for a long blast furnace life. In this paper, the embrittlement phenomenon of the hearth lining found in the blast furnace dissection has been described. Combining the migration figure of the thermocouple temperature in the blast furnace hearth, the evolution process of the carbon brick erosion and the heat transfer were analyzed. The results show that the embrittlement layer contains a large amount of ZnO, which accounts for more than 40%, and the thermal conductivity of the embrittled carbon brick is about 4.9 W/(m K). Moreover, due to the detachment of the embrittlement layer, the erosion evolution process of the hearth carbon brick exists as a cyclically periodic rising phenomenon together with the thermocouple temperature. Thereafter, the residual thickness of the carbon bricks and the temperature of the thermocouples during the formation of the embrittlement layer and the protective layer were calculated quantitatively.

Similar content being viewed by others

References

T.J. Yang, J.L. Zhang, Z.J. Liu, and K.X. Jiao, Ironmaking 37, 1 (2018).

X.L. Wang, Metallurgy of iron and steel (Part I: ironmaking) (Beijing: Metallurgical Industry Press, 2019).

S.R. Zhang and Z.J. Yu, Abnormal conditions and accident treatments of blast furnace (Beijing: Metallurgical Industry Press, 2012).

X.Y. Fan, K.X. Jiao, J.L. Zhang, K.D. Wang, and Z.Y. Chang, ISIJ Int. 58, 1775 (2018).

Z.J. Liu, J.L. Zhang, and T.J. Yang, ISIJ Int. 52, 1713 (2012).

C. Zhou, G.W. Tang, J.C. Wang, D. Fu, T. Okosun, A. Silaen, and B. Wu, JOM. 68, 1353 (2016).

K. Takatani, T. Inada, and K. Takata, ISIJ Int. 41, 1139 (2001).

T. Inada, A. Kasai, K. Nakano, S. Komatsu, and A. Ogawa, ISIJ Int. 49, 470 (2009).

V. Panjkovic, J.S. Truelove, and P. Zulli, Ironmak Steelmak 18, 390 (2013).

L. Shao and H. Saxén, Steel Res. Int. 83, 878 (2012).

K.X. Jiao, J.L. Zhang, Z.J. Liu, F. Liu, and L.S. Liang, Int. J. Miner. Met. Mater. 23, 16 (2016).

K.X. Jiao, J.L. Zhang, Z.J. Liu, S.B. Kuang, and Y.X. Liu, ISIJ Int. 57, 48 (2017).

K.X. Jiao, J.L. Zhang, Z.J. Liu, C.L. Chen, and Y.X. Liu, ISIJ Int. 56, 1956 (2016).

K.X. Jiao, J.L. Zhang, Z.J. Liu, M. Xu, and F. Liu, Int. J. Miner. Met. Mater. 22, 1017 (2015).

K.X. Jiao, J.L. Zhang, Q.F. Hou, Z.J. Liu, and G.W. Wang, Steel Res. Int. 88, 1 (2017).

K.X. Jiao, X.Y. Fan, J.L. Zhang, K.D. Wang, and Y.A. Zhao, Ceramic Int. 44, 19981 (2018).

L.S. Liang, Y.M. Chen, and G. Wei, China Metall. 6, 14 (2013).

R.L. Zhu, G.J. Sun, C.C. Lin, in AISTech Proceedings (2015) p. 298.

S. Gupta, D. French, R. Sakurovs, M. Grigore, H. Sun, T. Cham, T. Hilding, M. Hallin, B. Hindblom, and V. Sahajwalla, Prog. Energy Combust. Sci. 34, 155 (2008).

Z.Y. Chang, K.X. Jiao, and J.L. Zhang, Metall. Mater. Trans. B 49, 2956 (2018).

K. Kazuberns, S. Gupta, M. Grigore, D. French, R. Sakurovs, and M. Hallin, Energy Fuels 22, 3407 (2008).

K.X. Jiao, J.L. Zhang, Z.J. Liu, Z.Z. Liu, Y. Deng, and X.Y. Fan, Metall. Res. Technol. 115, 109 (2018).

Acknowledgements

This work was financially supported by the National Science Foundation of China (51704019) and the Young Elite Scientists Sponsorship Program by CAST (2018QNRC001). We are very grateful to anonymous reviewers for their warm work and suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiao, KX., Wang, C., Zhang, JL. et al. Heat Transfer Evolution Process in Hearth Based on Blast Furnace Dissection. JOM 72, 1935–1942 (2020). https://doi.org/10.1007/s11837-020-04090-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04090-y