Abstract

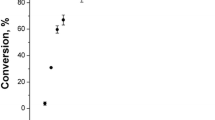

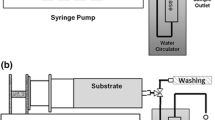

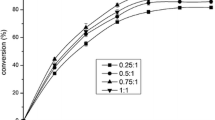

Candida antarctica lipase is inactivated in a mixture of vegetable oil and more than 1∶2 molar equivalent of methanol against the total fatty acids. We have revealed that the inactivation was eliminated by three successive additions of 1∶3 molar equivalent of methanol and have developed a three-step methanolysis by which over 95% of the oil triacylglycerols (TAG) were converted to their corresponding methyl esters (ME). In this study, the lipase was not inactivated even though 2∶3 molar equivalent of methanol was present in a mixture of acylglycerols (AG) and 33% ME (AG/ME33). This finding led to a two-step methanolysis of the oil TAG: The first-step was conducted at 30°C for 12 h with shaking in a mixture of the oil, 1∶3 molar equivalent of methanol, and 4% immobilized lipase; the second-step reaction was done for 24 h after adding 2∶3 molar equivalent of methanol (36 h in total). The two-step methanolysis achieved more than 95% of conversion. When two-step reaction was repeated by transferring the immobilized lipase to a fresh substrate mixture, the enzyme could be used 70 cycles (105 d) without any decrease in the conversion. From the viewpoint of the industrial production of biodiesel fuel production, the two-step reaction was conducted using a reactor with impeller. However, the enzyme carrier was easily destroyed, and the lipase could be used only several times. Thus, we attempted flow reaction using a column packed with immobilized Candida lipase. Because the lipase packed in the column was drastically inactivated by feeding a mixture of AG/ME33 and 2∶3 molar equivalent of methanol, three-step flow reaction was performed using three columns packed with 3.0 g immobilized lipase. A mixture of vegetable oil and 1∶3 molar equivalent of methanol was fed into the first column at a constant flow rate of 6.0 mL/h. The eluate and 1∶3 molar equivalent of methanol were mixed and then fed into the second column at the same flow rate. The final step reaction was done by feeding a mixture of eluate from the second column and 1∶3 molar equivalent of methanol at the same flow rate. The ME content in the final-step eluate reached 93%, and the lipase could be used for 100 d without any decrease in the conversion.

Similar content being viewed by others

References

Krawezyk, T., Biodiesel: Alternative Fuel Makes Inroads but Hurdles Remain, INFORM 7:800–815 (1996).

Cvengros, J. and Z. Cvengrosová, Quality Control of Rapeseed Oil Methyl Esters by Determination of Acyl Conversion, J. Am. Oil Chem. Soc. 71:1349–1352 (1994).

Mittelbach, M., Lipase-Catalyzed Alcoholysis of Sunflower Oil, Ibid. 67:168–170 (1990).

Linko, Y.-Y., M. Lämsä, A. Huhtala, and P. Linko, Lipase-Catalyzed Transesterification of Rapeseed Oil and 2-Ethyl-1-hexanol, Ibid. 71:1411–1414 (1994).

Linko, Y.-Y., M. Lämsä, X. Wu, E. Uosukainen, J. Seppälä, and P. Linko, Biodegradable Products by Lipase Biocatalysis, J. Biotechnol. 66:41–50 (1998).

Show, J.-F., and D.-L. Wang, Lipase-Catalyzed Ethanolysis and Isopropanolysis of Triglycerides with Long-Chain Fatty Acids, Enzyme Microb. Technol. 13:544–546 (1991).

Breivik, H., G.G. Haraldsson, and B. Kristinsson, Preparation of Highly Purified Concentrates of Eicosapentaenoic Acid and Docosahexaenoic Acid, J. Am. Oil Chem. Soc., 74:1425–1429 (1997).

Wu, W.H., T.A. Foglia, W.N. Marmer, and J.G. Phillips, Optimizing Production of Ethyl Esters of Grease Using 95% Ethanol by Response Surface Methodology, Ibid. 76:517–521 (1999).

Nelson, L.A., T.A. Foglia, and W.N. Marmer, Lipase-Catalyzed Production of Biodiesel, Ibid. 73:1191–1195 (1996).

Selmi, B., and D. Thomas, Immobilized Lipase-Catalyzed Ethanolysis of Sunflower Oil in a Solvent-Free Medium, Ibid. 75:691–695 (1998).

De, B.K., D.K. Bhattacharyya, and C. Bandhu, Enzymatic Synthesis of Fatty Alcohol Esters by Alcoholysis, Ibid. 76:451–453 (1999).

Shimada, Y., Y. Watanabe, T. Samukawa, A. Sugihara, H. Noda, H. Fukuda, and Y. Tominaga, Conversion of Vegetable Oil to Biodiesel Using Immobilized Candida antarctica Lipase, Ibid. 76:789–793 (1999).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Watanabe, Y., Shimada, Y., Sugihara, A. et al. Continuous production of biodiesel fuel from vegetable oil using immobilized Candida antarctica lipase. J Amer Oil Chem Soc 77, 355–360 (2000). https://doi.org/10.1007/s11746-000-0058-9

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11746-000-0058-9