Abstract

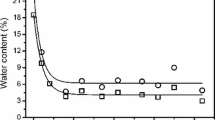

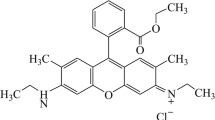

Three organoclays were prepared by mixing an Algerian halloysite with a solution of hexadecyltrimethylammonium bromide (HDTMA-Br) equivalent to six times the cation-exchange capacity of our clay. Unlike a majority of studies which were focused on the initial concentration of the intercalating agent, this paper investigates the influence of the reaction time for a given initial concentration. Three intercalation times were examined: 2, 7, and 14 days. The resulting organoclays were analyzed by XRD, FTIR, TG–DTA, TEM, and N2 adsorption–desorption. The intercalation of HDTMA+ cations begins by a latency period up to 2 days, during which these cations interact with the external surface of halloysite. From 2 to 7 days, they migrate into the interlayer spaces, leading to an expansion of the basal distance from 7.3 to 26.0 Å. Between 7 and 14 days, the expansion remains unchanged for an intercalation rate around 42%. FTIR analysis proved that the surfactant interacts with the inner surface hydroxyl groups. From 200 °C, thermal analysis highlighted a succession of stages linked to the removal of HDTMA+. The TEM images showed a decrease in the outer diameter of the intercalated nanotubes with an enlargement of lumen diameter up to 20 nm. The arrangement of HDTMA+ species into interlayer spaces reflected a paraffin-type monolayer configuration. Knowing that the intercalation of organic compounds into the clay minerals changes their behavior from hydrophilic to hydrophobic, a nanotubular organohalloysite with a basal expansion of 26.0 Å could be a highly effective adsorbent for wastewater decontamination.

Similar content being viewed by others

References

Abbas A, Sallam AS, Usman AA, Al-Wabel MI (2017) Organoclay-based nanoparticles from montmorillonite and natural clay deposits: synthesis, characteristics, and application for MTBE removal. Appl Clay Sci 142:21–29. https://doi.org/10.1016/j.clay.2016.11.028

Abdullayev E, Lvov Y (2016) Halloysite for controllable loading and release. In: Yuan P, Thill A, Bergaya F (eds) Nanosized tubular clay minerals: halloysite and imogolite. Chapter 22. Elsevier, Amsterdam

Belkassa K, Bessaha F, Marouf-Khelifa K, Batonneau-Gener I, Comparot JD, Khelifa A (2013) Physicochemical and adsorptive properties of a heat-treated and acid leached Algerian halloysite. Colloids Surf A 421:26–33. https://doi.org/10.1016/j.colsurfa.2012.12.048

Bessaha F, Marouf-Khelifa K, Batonneau-Gener I, Khelifa A (2016) Characterization and application of heat-treated and acid-leached halloysites in the removal of malachite green: adsorption, desorption, and regeneration studies. Desalin Water Treat 57:14609–14621. https://doi.org/10.1080/19443994.2015.1063090

Campbell RA, Parker SR, Day JPR, Bain CD (2004) External reflection FTIR spectroscopy of the cationic surfactant hexadecyltrimethylammonium bromide (CTAB) on an overflowing cylinder. Langmuir 20:8740–8753. https://doi.org/10.1021/la048680x

Chmielarz L, Kowalczyk A, Wojciechowska M, Boroń P, Dudek B, Michalik M (2014) Montmorillonite intercalated with SiO2, SiO2–Al2O3 or SiO2–TiO2 pillars by surfactant-directed method as catalytic supports for DeNOx process. Chem Pap 68:1219–1227. https://doi.org/10.2478/s11696-013-0463-0

Frost RL, Kristof J, Horvath E, Kloprogge JT (2000) Rehydration and phase changes of potassium acetate-intercalated halloysite at 298 K. J Colloid Interface Sci 226:318–327. https://doi.org/10.1006/jcis.2000.6807

Gammoudi S, Frini-Srasra N, Srasra E (2012) Influence of exchangeable cation of smectite on HDTMA adsorption: equilibrium, kinetic and thermodynamic studies. Appl Clay Sci 69:99–107. https://doi.org/10.1016/j.clay.2011.11.011

Gładysz-Płaska A, Majdan M, Pikus S, Sternik D (2012) Simultaneous adsorption of chromium (VI) and phenol on natural red clay modified by HDTMA. Chem Eng J 179:140–150. https://doi.org/10.1016/j.cej.2011.10.071

Gomdje VH, Rahman AN, Wahabou A (2017) Synthesis of organoclay and its applications in electrochemical detection of paracetamol. Der Chem Sin 8:206–217

Guessoum M, Nekkaa S, Fenouillot-Rimlinger F, Haddaoui N (2012) Effects of kaolin surface treatments on the thermomechanical properties and on the degradation of polypropylene. Int J Polym Sci . https://doi.org/10.1155/2012/549154 (Article ID 549154)

He H, Ding Z, Zhu J, Yuan P, Xu Y, Yang D, Frost R (2005a) Thermal characterization of surfactant-modified montmorillonites. Clays Clay Miner 53:287–293. https://doi.org/10.1346/CCMN.2005.0530308

He H, Galy J, Gerard JF (2005b) Molecular simulation of the interlayer structure and the mobility of alkyl chains in HDTMA+/montmorillonite hybrids. J Phys Chem B 109:13301–13306. https://doi.org/10.1021/jp0517495

Hundáková M, Tokarský J, Valášková M, Slobodian P, Pazdziora E, Kimmer D (2015) Structure and antibacterial properties of polyethylene/organo-vermiculite composites. Solid State Sci 48:197–204. https://doi.org/10.1016/j.solidstatesciences.2015.08.011

Kannan C, Sundaram T, Palvannan T (2008) Environmentally stable adsorbent of tetrahedral silica and non-tetrahedral alumina for removal and recovery of malachite green dye from aqueous solution. J Hazard Mater 157:137–145. https://doi.org/10.1016/j.jhazmat.2007.12.116

Lagaly G (1986) Smectitic clays as ionic macromolecules. In: Wilson AD, Prosser HJ (eds) Developments of ionic polymers, vol 2. Elsevier, London, pp 77–140

Lagaly G, Ogawa M, Dékány I (2013) Clay mineral–organic interactions. In: Bergaya F, Lagaly G (eds) Handbook of clay science: fundamentals. Chapter 10.3. Elsevier, Amsterdam, p 435

Lapides I, Borisover M, Yariv S (2011) Thermal analysis of hexadecyltrimethylammonium–montmorillonites. J Therm Anal Calorim 105:921–929. https://doi.org/10.1007/s10973-011-1304-4

Li Z, Gallus L (2005) Surface configuration of sorbed hexadecyltrimethylammonium on kaolinite as indicated by surfactant and counterion, sorption cation, desorption, and FTIR. Colloids Surf A 264:61–67. https://doi.org/10.1016/j.colsurfa.2005.05.016

Liang Y, Ding H, Wang Y, Liang N, Wang G (2013) Intercalation of cetyl trimethylammonium ion into sericite in the solvent of dimethyl sulfoxide. Appl Clay Sci 74(2013):109–114. https://doi.org/10.1016/j.clay.2013.01.009

Madejová J (2003) FTIR techniques in clay mineral studies. Vib Spectrosc 31:1–10. https://doi.org/10.1016/S0924-2031(02)00065-6

Madejová J, Pentrák M, Pálková H, Komadel P (2010) IR spectroscopy of clay minerals and clay nanocomposites Spectrosc. Prop Inorg Organomet Compd 41:22–71. https://doi.org/10.1039/9781849730853-00022

Mahrez N, Bendenia S, Marouf-Khelifa K, Batonneau-Gener I, Khelifa A (2015) Improving of the adsorption capacity of halloysite nanotubes intercalated with dimethyl sulfoxide. Compos Interfaces 22:403–417. https://doi.org/10.1080/09276440.2015.1036581

Manikandan D, Divakar D, Sivakumar T (2007) Utilization of clay minerals for developing Pt nanoparticles and their catalytic activity in the selective hydrogenation of cinnamaldehyde. Catal Commun 8:1781–1786. https://doi.org/10.1016/j.catcom.2007.02.007

Mellouk S, Cherifi S, Sassi M, Marouf-Khelifa K, Bengueddach A, Schott J, Khelifa A (2009) Intercalation of halloysite from Djebel Debagh (Algeria) and adsorption of copper ions. Appl Clay Sci 44:230–236. https://doi.org/10.1016/j.clay.2009.02.008

Naranjo PM, Molina J, Sham EL, Farfán Torres EM (2015) Synthesis and characterization of HDTMA-organoclays: insights into their structural properties. Quim Nova 38:166–171. https://doi.org/10.5935/0100-4042.20140302

Nunes AR, Araújo KO, Moura AO, Prado AS (2018) Magadiite as a support for the controlled release of herbicides. Chem Pap 72:479–486. https://doi.org/10.1007/s11696-017-0300-y

Park Y, Ayoko GA, Kristof J, Horváth E, Frost RL (2012) Thermal stability of organoclays with mono-and di-alkyl cationic surfactants. J Therm Anal Calorim 110:1087–1093. https://doi.org/10.1007/s10973-011-2025-4

Pei Y, Wang M, Tian D, Xu X, Yuan L (2015) Synthesis of core–shell SiO2@ MgO with flower like morphology for removal of crystal violet in water. J Colloid Interface Sci 453:194–201. https://doi.org/10.1016/j.jcis.2015.05.003

Plachá D, Martynková GS, Rümmeli MH (2008) Preparation of organovermiculites using HDTMA: structure and sorptive properties using naphthalene. J Colloid Interface Sci 327:341–347. https://doi.org/10.1016/j.jcis.2008.08.026

Rouquerol F, Rouquerol J, Sing K (1999) Adsorption by powders & porous solids, principles, methodology and applications. Academic Press, London

Salazar-Camacho C, Villalobos M, Rivas-Sánchez M, Arenas-Alatorre J, Alcaraz-Cienfuegos J, Gutiérrez-Ruiz ME (2013) Characterization and surface reactivity of natural and synthetic magnetites. Chem Geol 347:233–245. https://doi.org/10.1016/j.chemgeo.2013.03.017

Senoussi H, Osmani H, Courtois C, Bourahli MeH (2016) Mineralogical and chemical characterization of DD3 kaolin from the east of Algeria. Bol Soc Esp Ceram Vidr 55:121–126. https://doi.org/10.1016/j.bsecv.2015.12.001

Shirzad-Siboni M, Khataee A, Hassani A, Karaca S (2015) Preparation, characterization and application of a CTAB-modified nanoclay for the adsorption of an herbicide from aqueous solutions: kinetic and equilibrium studies. C R Chim 18:204–214. https://doi.org/10.1016/j.crci.2014.06.004

Špírková M, Bober P, Kotek J, Stejskal J (2013) Bi-hybrid coatings: polyaniline-montmorillonite filler in organic–inorganic polymer matrix. Chem Pap 67:1020–1027. https://doi.org/10.2478/s11696-012-0299-z

Sun Z, Park Y, Zheng S, Ayoko GA, Frost RL (2013) Thermal stability and hot-stage Raman spectroscopic study of Ca-montmorillonite modified with different surfactants: a comparative study. Thermochim Acta 569:151–160. https://doi.org/10.1016/j.tca.2013.07.022

Vaia RA, Teukolsky RK, Giannelis EP (1994) Interlayer structure and molecular environment of alkylammonium layered silicates. Chem Mater 6:1017–1022. https://doi.org/10.1021/cm00043a025

Wang L, Chen Z, Wang X, Yan S, Wang J, Fan Y (2011) Preparations of organo-vermiculite with large interlayer space by hot solution and ball milling methods: a comparative study. Appl Clay Sci 51:151–157. https://doi.org/10.1016/j.clay.2010.11.023

Weiss A, Choy JH, Meyer H, Becker HO (1981) Hydrogen reorientation, a primary step of intercalation reactions into kaolinite. In: Proceedings of the international clay conference, Bologna, Pavia, Abstracts 331

Wiewióra A, Brindley GW (1969) Potassium acetate intercalation in kaolinites and its removal: effect of material characteristics. In: Heller L (ed) Proceedings of the international clay conference, Tokyo. Israel University Press, Jerusalem, pp 723–733

Xi Y, Mallavarapu M, Naidu R (2010) Preparation, characterization of surfactants modified clay minerals and nitrate adsorption. Appl Clay Sci 48:92–96. https://doi.org/10.1016/j.clay.2009.11.047

Yah WO, Takahara A, Lvov Y (2012) Selective modification of halloysite lumen with octadecylphosphonic acid: new inorganic tubular micelle. J Am Chem Soc 134:1853–1859. https://doi.org/10.1021/ja210258y

Yu WH, Ren QQ, Tong DS, Zhou CH, Wang H (2014) Clean production of CTAB-montmorillonite: formation mechanism and swelling behavior in xylene. Appl Clay Sci 97–98:222–234. https://doi.org/10.1016/j.clay.2014.06.007

Yuan P, Southon PD, Liu Z, Green MER, Hook JM, Antill SJ, Kepert CJ (2008) Functionalization of halloysite clay nanotubes by grafting with γ-aminopropyltriethoxysilane. J Phys Chem C 112:15742–15751. https://doi.org/10.1021/jp805657t

Zaghouane-Boudiaf H, Boutahala M (2011) Preparation and characterization of organo- montmorillonites. Application in adsorption of the 2,4,5-trichlorophenol from aqueous solution. Adv Powder Technol 22:735–740. https://doi.org/10.1016/j.apt.2010.10.014

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mehdi, K., Bendenia, S., Lecomte-Nana, G.L. et al. A new approach about the intercalation of hexadecyltrimethylammonium into halloysite: preparation, characterization, and mechanism. Chem. Pap. 73, 131–139 (2019). https://doi.org/10.1007/s11696-018-0558-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-018-0558-8