Abstract

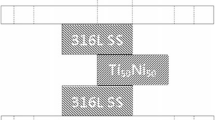

Filler metal of a low-melting-point (917 °C) Ti-21Ni-14Cu was brazed onto the substrate of Ti-6Al-4V alloy at 960 °C for 2,4, and 8 h to investigate the microstructural evolution and electrochemical characteristics of the brazed metal as a function of the period of brazing time. Optical microscopy, scanning and transmission electron microscopy, and x-ray diffractometry were used to characterize the microstructure and phase of the brazed metal; also, the potentiostat was used for corrosion study. Experimental results indicate that diffusion of copper and nickel from the filler metal into the equiaxed a plus intergranular β structure of Ti-6Al-4V substrate causes the lamellar Widmanstätten structure to form. The intermetallic Ti2Ni phase existing in the prior filler metal diminishes, while the Ti2Cu phase can be identified for the metal brazed at 960 °C for 2 h, but the latter phase decreases with time. Advantage might be taken from the evidence of faster diffusion of nickel than copper along the β phase to the substrate. In deaerated Hank’s solution, corrosion potential, corrosion current density, and critical potential for active-to-passive transition decrease while the passivation range broadens with the period of brazing time. However, all the brazed metals, immersed for different periods in oxygen-saturated Hank’s solution, show similar corrosion behavior, irrespective of the brazing time.

Similar content being viewed by others

References

D.G. Howden and R.W. Monroe, Suitable Alloys for Brazing Titanium Heat Exchangers, Weld J., Vol 51 (No. 1), 1972, p 31–36

S.W. Lan, Laminated Brazing Filler Metals for Titanium Assemblies, Weld. J., Vol 61 (No. 10), 1982, p 23–28

R.R. Well, Low Temperature Large-Area Brazing of Damage Tolerant Titanium Structures, Weld. Res. Suppl, Vol 54 (No. 10), 1975, p 348–356

T. Onzawa, A. Suzumura, and M.W. Ko, Brazing of Titanium Using Low-Melting-Point Ti-Based Filler Metals, Weld. Res. sSuppl., Vol 69 (No. 12), 1990, p 462–467

E. Chang and C.H. Chen, Low-Melting-Point Titanium-Base Alloys—Part 1: Characteristics of Two-, Three-and Four-Component Filler Metals, J. Maler. Eng. Perform., Vol 6 (No. 6), 1997, p 792–796

I. Tuah-Poku, M. Dollar, and T.B. Massalski, A Study of the Transient Liquid Phase Bonding Process Applied to a Ag/Cu/Ag Sandwich Joint, Metall. Trans. A, Vol 19 (No. 3), 1988, p 675–686

S.R. Seagle and L.J. Bartlo, Physical Metallurgy and Metallography of Titanium Alloys, Titanium and Titanium Alloys Source Book, M.J. Donachie, Jr., Ed., American Society for Metals, 1982, p 23–32

C.G. Rhodes, A.K. Ghosh, and R.A. Spurling, Ti-6Al-4V-2Ni as a Matrix Material for a SiC-Reinforced Composite, Metall. Trans.A.Vol 18(No. 12), 1987, p 2151–2156

M. Pourbaix, Atlas of Electrochemical Equilibria in Aqueous Solutions, Pergamon Press, 1966

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chang, E., Chen, C.H. Low-melting-point titanium-base brazing alloys—part 2: Characteristics of brazing Ti-21Ni-14Cu on Ti-6Al-4v substrate. J. of Materi Eng and Perform 6, 797–803 (1997). https://doi.org/10.1007/s11665-997-0084-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-997-0084-2