Abstract

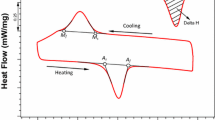

This experimental work reports the results of a study addressing tool wear, surface topography, and x-ray diffraction analysis for the finish cutting process of room-temperature austenitic NiTi alloy. Turning operation of NiTi alloy was conducted under dry, minimum quantity lubrication (MQL) and cryogenic cooling conditions at various cutting speeds. Findings revealed that cryogenic machining substantially reduced tool wear and improved surface topography and quality of the finished parts in comparison with the other two approaches. Phase transformation on the surface of work material was not observed after dry and MQL machining, but B19′ martensite phase was found on the surface of cryogenically machined samples.

Similar content being viewed by others

References

T. Duerig, A. Pelton, and D. Stockel, An Overview of Nitinol Medical Applications, Elsevier Science, Oxford, 1999, p 149–160

B. Thierry, M. Tabrizian, C. Trepanier, O. Savadogo, and L.H. Yahia, Effect of Surface Treatment and Sterilization Processes on the Corrosion Behavior of NiTi Shape Memory Alloy, J. Biomed. Mater. Res., 2000, 51, p 685–693

K. Weinert, V. Petzoldt, and D. Kotter, Turning and Drilling of NiTi Shape Memory Alloys, CIRP Ann. Manuf. Technol, 2004, 53, p 65–68

K. Weinert and V. Petzoldt, Machining of NiTi Based Shape Memory Alloys, Mater. Sci. Eng., 2004, A378, p 180–184

Y. Kaynak, H.E. Karaca, R.D. Noebe, and I.S. Jawahir, Tool-Wear Analysis in Cryogenic Machining of NiTi Shape Memory Alloys: A Comparison of Tool-Wear Performance with Dry and MQL Machining, Wear, 2013, 306, p 51–63

I.S. Jawahir, E. Brinksmeier, R. M’Saoubi, D.K. Aspinwall, J.C. Quteiro, D. Meyer, D. Umbrello, and A.D. Jayal, Surface Integrity in Material Removal Processes: Recent Advances, CIRP Ann. Manuf. Technol., 2011, 60, p 603–626

R. M’Saoubi, J. Outeiro, H. Chandrasekaran, O. Dillon, Jr., and I.S. Jawahir, A Review of Surface Integrity in Machining and its Impact on Functional Performance and Life of Machined Products, Int. J. Sustain. Manuf., 2008, 1, p 203–236

J. Outeiro, J. Pina, R. M’saoubi, F. Pusavec, and I.S. Jawahir, Analysis of Residual Stresses Induced by Dry Turning of Difficult-to-Machine Materials, CIRP Ann. Manuf. Technol., 2008, 57, p 77–80

A. Jayal, F. Badurdeen, O. Dillon, Jr., and I.S. Jawahir, Sustainable Manufacturing: Modeling and Optimization Challenges at the Product, Process and System Levels, CIRP J. Manuf. Sci. Technol., 2010, 2, p 144–152

Y. Guo, A. Klink, C. Fu, and J. Snyder, Machinability and Surface Integrity of Nitinol Shape Memory Alloy, CIRP Ann. Manuf. Technol., 2013, 62, p 83–86

Y. Kaynak, H. Tobe, R.D. Noebe, H. Karaca, and I.S. Jawahir, The Effects of Machining on Microstructure and Transformation Behavior of NiTi Alloy, Scr. Mater., 2014, 74, p 60–63

F. Pusavec, H. Hamdi, J. Kopac, and I.S. Jawahir, Surface Integrity in Cryogenic Machining of Nickel Based Alloy—Inconel 718, J. Mater. Process. Technol., 2011, 211, p 773–783

Y. Kaynak, H. Karaca, I.S. Jawahir, Cryogenic Machining of NiTi Shape Memory Alloy, 6th Int. Conference and Exhibition on Design and Production of Machines and Dies/Molds, 2011, p 23–26

Z.Y. Wang, K.P. Rajurkar, Cryogenic machining of hard-to-cut materials, Wear, 2000, 239, p 168–175

S.Y. Hong, I. Markus, W. Jeong, New cooling approach and tool life improvement in cryogenic machining of titanium alloy Ti-6Al-4V, Int. J. Mach. Tool. Manu., 2001, 41, p 2245–2260

H. Shahabi and M. Ratnam, Assessment of Flank Wear and Nose Radius Wear from Workpiece Roughness Profile in Turning Operation Using Machine Vision, Int. J. Adv. Manuf. Techol., 2009, 43, p 11–21

Y. Kaynak, Evaluation of Machining Performance in Cryogenic Machining of Inconel 718 and Comparison with Dry and MQL Machining, Int. J. Adv. Manuf. Techol., 2014, 72, p 919–933

Y. Kaynak, H.E. Karaca, R.D. Noebe, and I.S. Jawahir, Analysis of Tool-Wear and Cutting Force Components in Dry, Preheated, and Cryogenic Machining of NiTi Shape Memory Alloys, Proc. CIRP, 2013, 8, p 498–503

M. Bermingham, J. Kirsch, S. Sun, S. Palanisamy, and M. Dargusch, New Observations on Tool Life, Cutting Forces and Chip Morphology in Cryogenic Machining Ti-6Al-4V, Int. J. Mach. Tools Manuf., 2011, 51, p 500–511

K.A. Venugopal, S. Paul, and A.B. Chattopadhyay, Growth of Tool Wear in Turning of Ti-6Al-4V Alloy Under Cryogenic Cooling, Wear, 2007, 262, p 1071–1078

M.C. Shaw, Metal Cutting Principles, Oxford Series on Advanced Manufacturing, 2nd ed., Oxford University Press, New York, 2005

Y. Kaynak, Process-Induced Surface Integrity in Machining of NiTi Shape Memory Alloys, University of Kentucky, Ph.D. dissertation, 2013

A. Ramesh, S. Melkote, L. Allard, L. Riester, and T. Watkins, Analysis of White Layers Formed in Hard Turning of AISI, 52100 Steel, Mater. Sci. Eng., 2005, A390, p 88–97

M.E. Mitwally and M. Farag, Effect of Cold Work and Annealing on the Structure and Characteristics of NiTi Alloy, Mater. Sci. Eng., 2009, A519, p 155–166

T. Hu, C. Wen, J. Lu, S. Wu, Y. Xin, W. Zhang, C. Chu, J. Chung, K. Yeung, and D. Kwok, Surface Mechanical Attrition Treatment Induced Phase Transformation Behavior in NiTi Shape Memory Alloy, J. Alloys Compd., 2009, 482, p 298–301

M. Szafarczyk and J. Chrzanowski, Tool Probe for Measuring Dimensional Wear and X-Coordinate of Turning Edge, Int. J. Adv. Manuf. Techol., 2004, 23, p 272–278

Acknowledgments

The author would like to offer sincere thanks to Prof. I.S. Jawahir and the Institute for Sustainable Manufacturing (ISM) for providing test equipments for this study. The author would like to thank Dr. S.W. Robertson from Nitinol Devices & Components, Inc. for providing work materials for this study. Additionally, gratitude is extended to Doc. Dr. M. Kemal Ozturk from Gazi University for providing XRD equipment.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaynak, Y. Machining and Phase Transformation Response of Room-Temperature Austenitic NiTi Shape Memory Alloy. J. of Materi Eng and Perform 23, 3354–3360 (2014). https://doi.org/10.1007/s11665-014-1058-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1058-9